Frame integration type multi-rod guiding continuous zooming device

A frame and screw technology, applied in the field of precision instruments, can solve problems such as image shaking, achieve the effect of eliminating connection gaps, improving the accuracy of assembly and adjustment, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

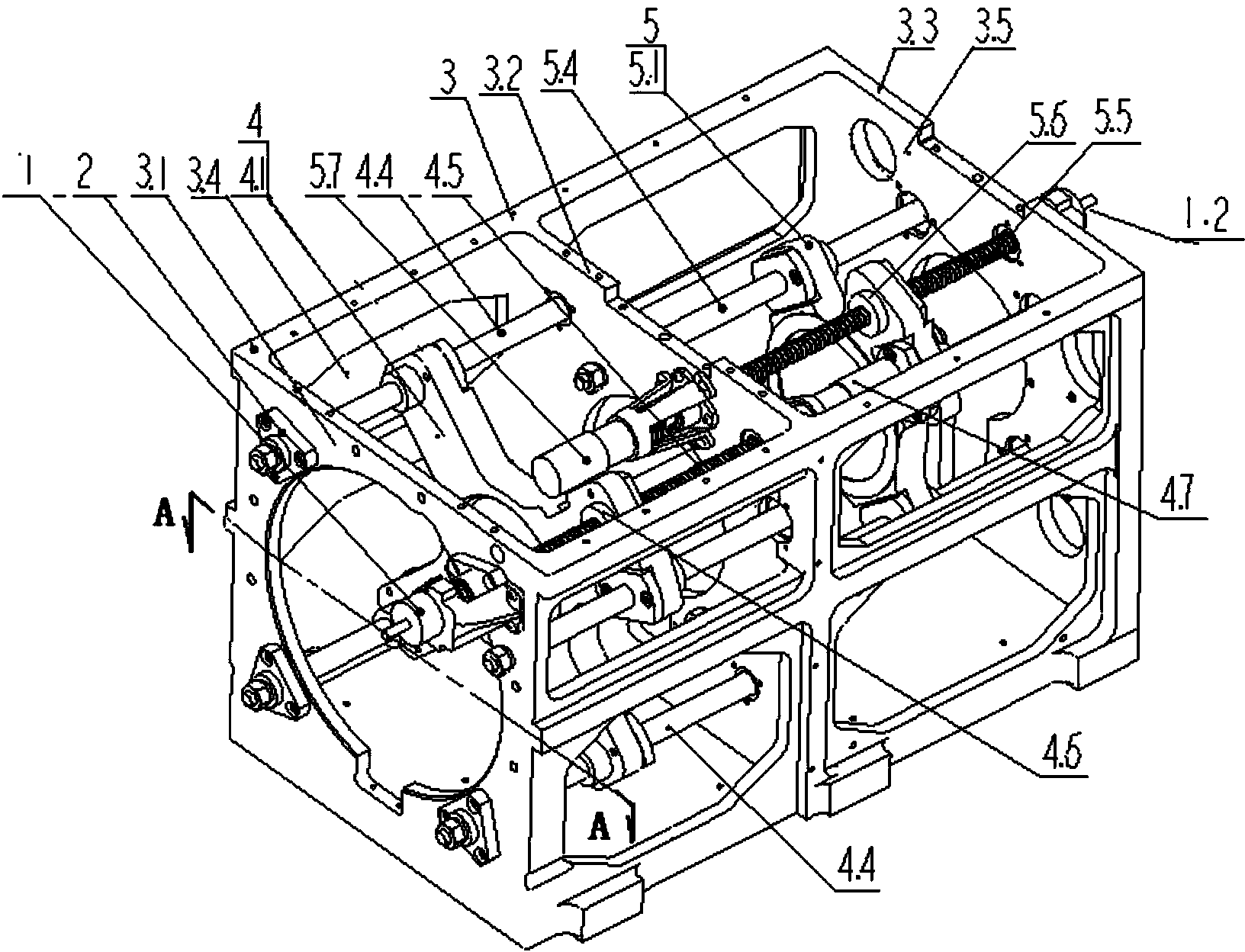

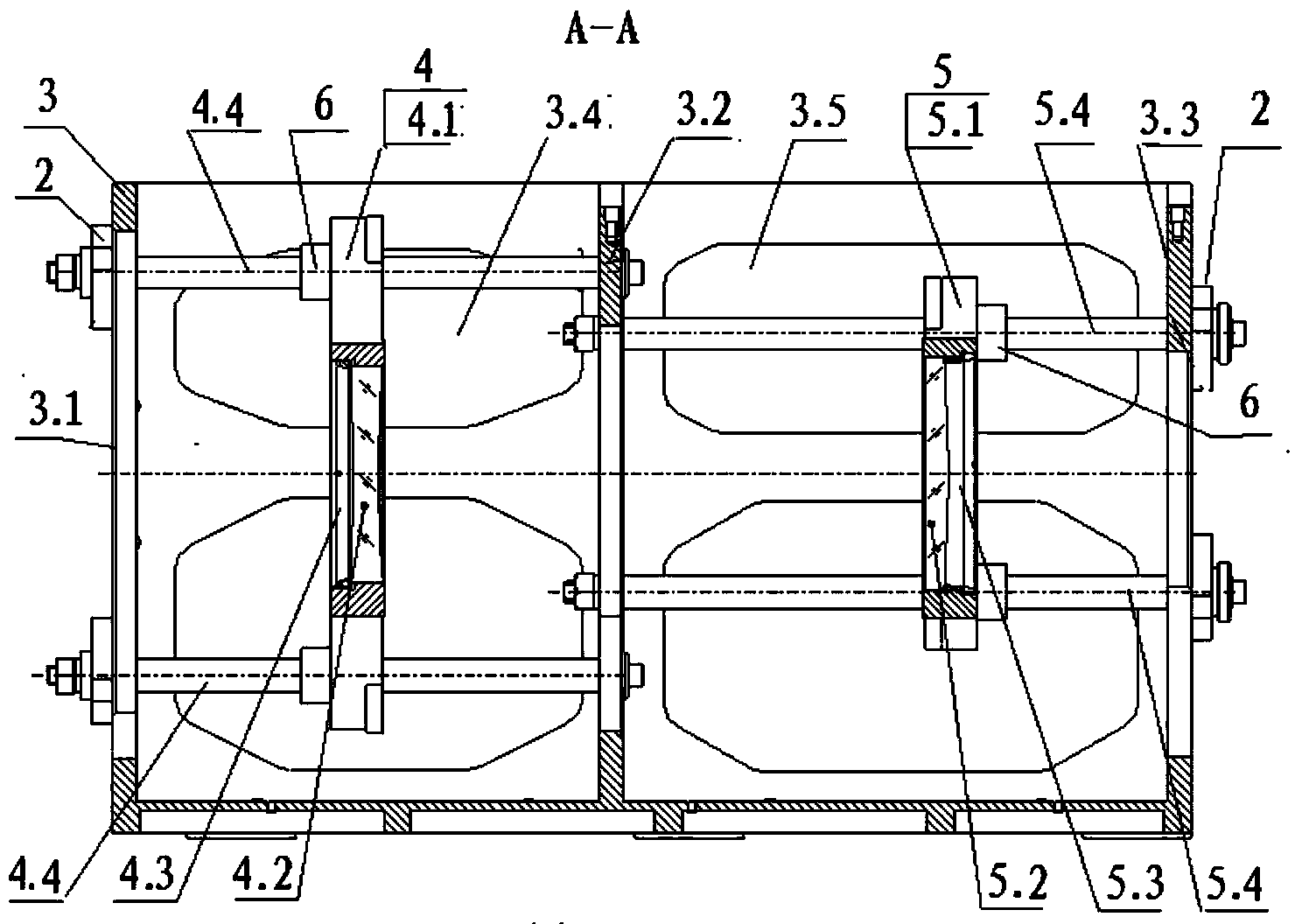

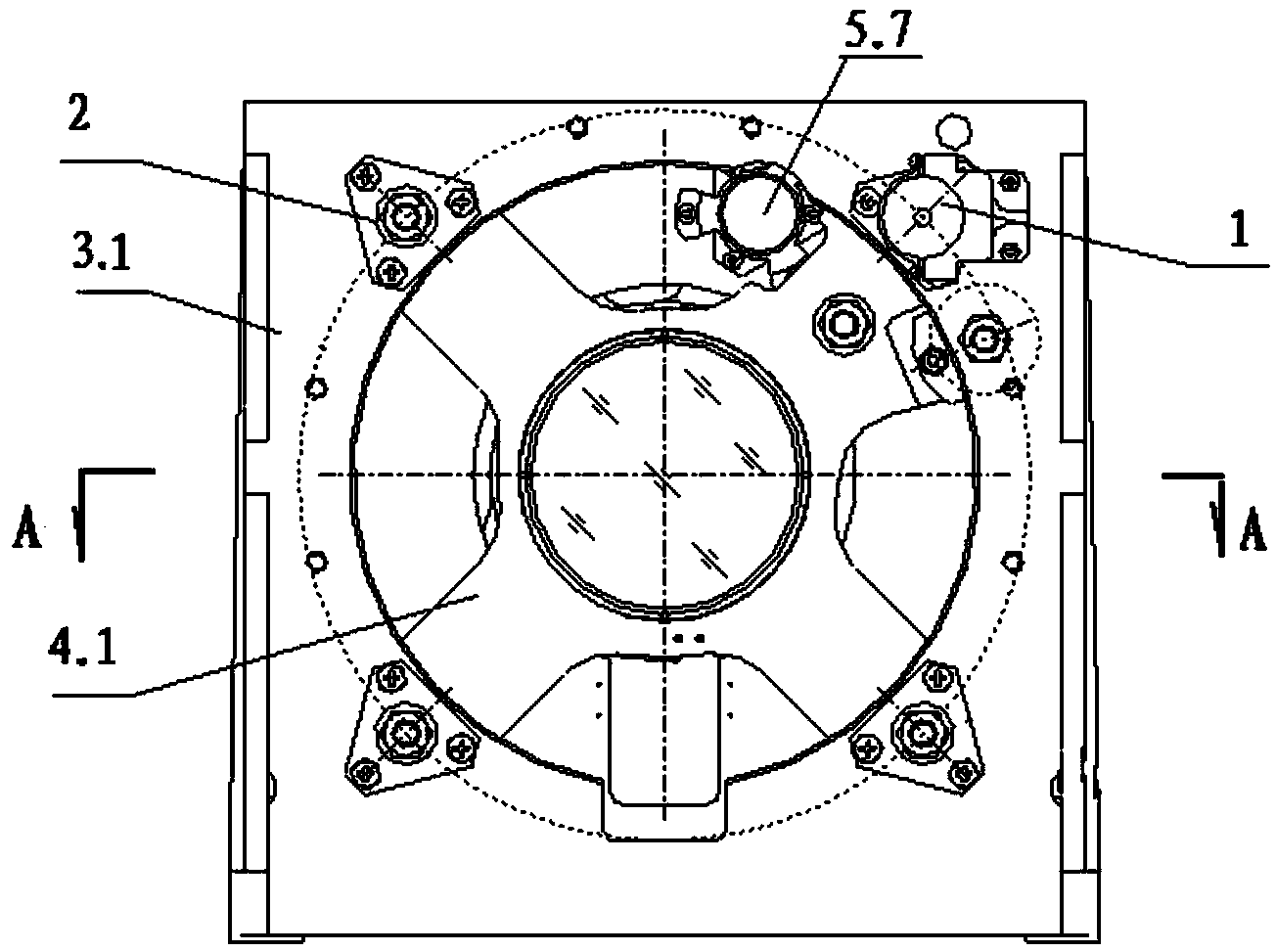

[0024] Example 1: for the basic example. Such as Figure 1-6 As shown, a frame-integrated multi-rod guiding continuous zoom device includes a frame 3 with two chambers, the frame 3 is a whole, and the chamber on one side of the middle vertical wall 3.2 is a zoom lens chamber 3.4, which is installed Comprising a zoom lens group 4 of a zoom lens 4.2, the chamber on the other side is a compensation lens chamber 3.5, which is installed with a compensation lens group 5 including a compensation lens 5.2; the zoom lens group 4 includes a zoom lens The seat 4.1 is installed with at least three linear bearings 6 for supporting the variable power lens seat 4.1 and one variable power lens seat screw nut 4.6 for driving the variable power lens seat 4.1 to move linearly; The variable power lens group guide rod 4.4 and the variable power lens group screw rod 4.5 passing through the variable power lens seat screw nut 4.6 are respectively connected to the variable power lens chamber wall 3...

Embodiment 2

[0025] Example 2:as a further example. The difference from Embodiment 1 is that the variable magnification encoder 1 is fixed on the variable magnification lens chamber wall 3.1 with its outer casing through an encoder pressure ring 9 and an encoder bracket 10; the compensation encoder 1.2 is fixed with its outer casing The body is fixed on the compensation lens chamber wall 3.3 via an encoder pressure ring 9 and an encoder holder 10. The linear bearing 6 and the screw nut 4.6 of the zoom lens holder are fixedly connected to the zoom lens holder 4.1 by screws; the linear bearing 6 and the compensation lens holder screw nut 5.6 are fixedly connected to the compensation lens holder 5.1 by screws. The zoom lens 4.2 is fixed in the middle of the zoom lens seat 4.1 through the zoom lens ring 4.3; the compensation lens 5.2 is fixed in the middle of the compensation lens seat 5.1 through the compensation lens ring 5.3. There are 4 linear bearings 6 installed on the zoom lens holde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com