Extractor hood with commutated plate and control method

A range hood and rectifier plate technology, which is applied in the fields of oil fume removal, heating method, household heating, etc., can solve the problems of easy vibration and falling off, unpleasant sound, inability to remove or close the rectifier plate, etc., so as to improve the user experience, The effect of reducing the clicking sound and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

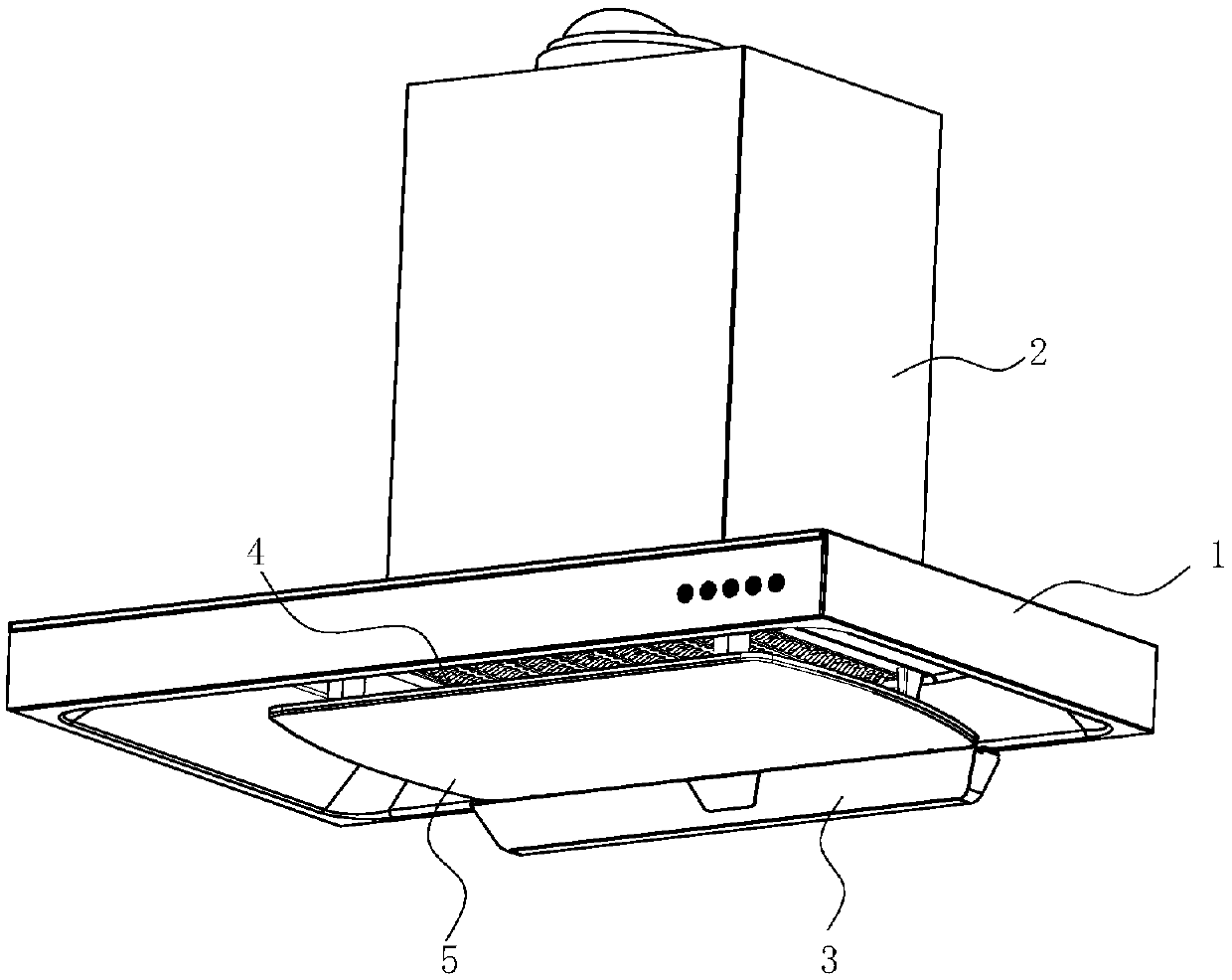

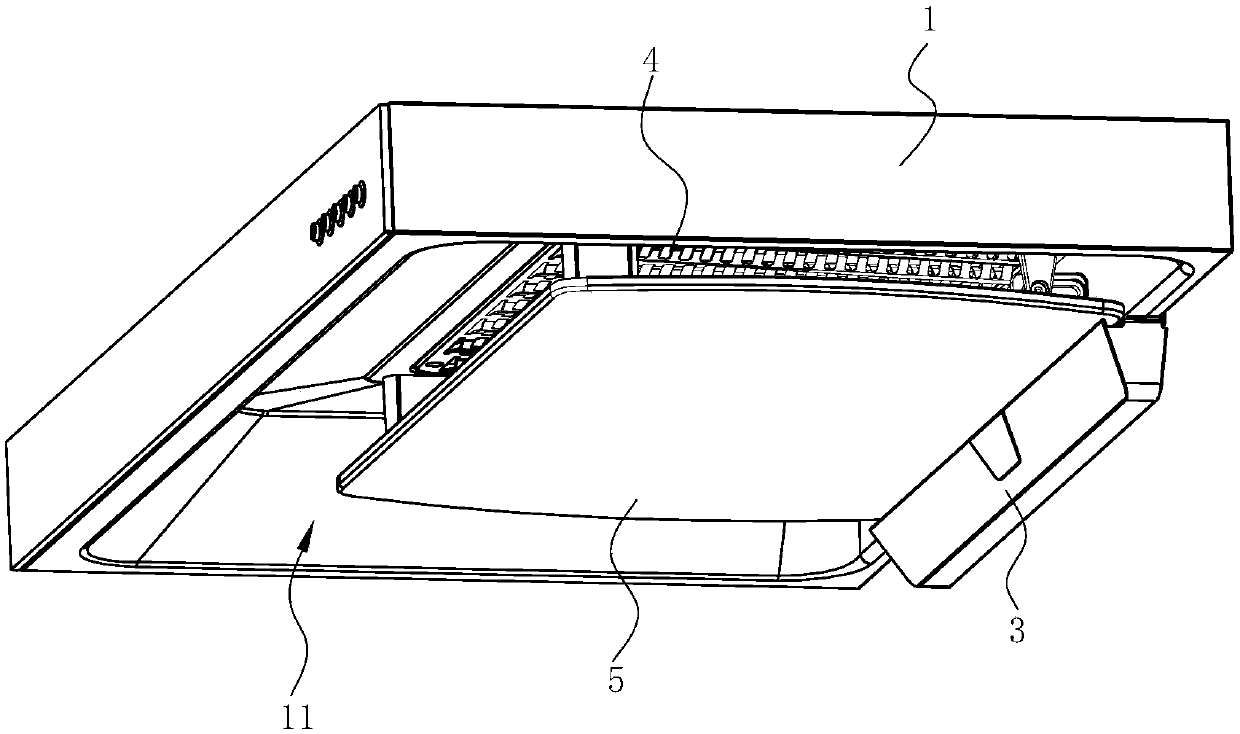

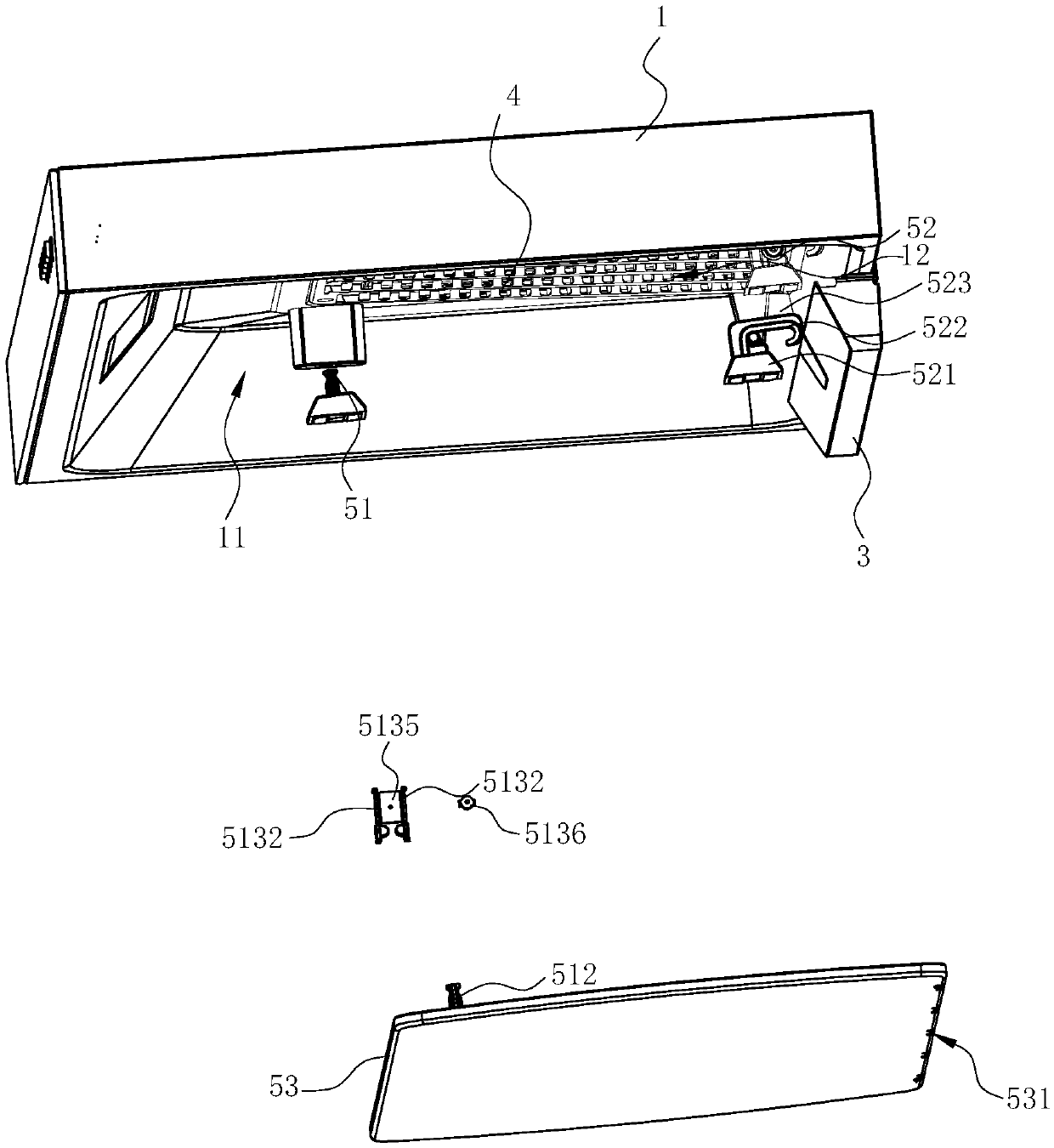

[0028] see Figure 1 to Figure 7 , a range hood, comprising a fume collection hood 1, a box 2 arranged above the fume collection hood 1, and a strip-shaped oil cup 3 arranged below the rear side of the fume collection hood 1. An upwardly concave smoke collection chamber 11 is formed in the smoke collection hood 1, and an air inlet 12 is opened on the smoke collection hood 1 to connect the smoke collection chamber 11 with the inside of the box body 2, so that oil fume can enter the box body 2 through the air inlet 12 and discharged through the fan system (not shown) in the box 2. The air inlet 12 is provided with a filter screen 4 .

[0029] A rectifying plate 5 is arranged in the smoke collecting chamber 11 below the air inlet 12 . The rear edge of the rectifying plate 5 is located above the oil cup 3 , and the edge of the rectifying plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com