Belt conveyor signal transmission control device and method used for ship unloader

A control device and signal transmission technology, applied in conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of excessive dust, reduced working time, and the belt speed detector does not work, and achieves low failure rate, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

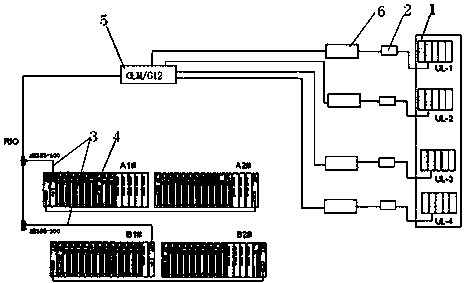

[0014] Such as figure 1 As shown, the belt conveyor signal transmission control device and method for ship unloaders provided by the present invention include wireless communication equipment and switching devices, and the wireless communication equipment refers to matching wireless transmitters 5 and wireless receivers 6, The belt conveyor PLC 4 is connected to the wireless transmitter 5 through the signal transmission line 3, the wireless receiver 6 is connected to the switching device 2 through the signal transmission line, and the switching device is connected to the PLC 1 of the ship unloader.

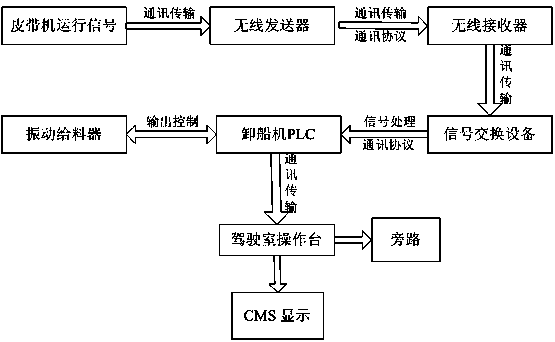

[0015] Such as figure 2 As shown, the present invention controls the operation of the belt conveyor in the substation by the PLC of the belt conveyor, and connects it to the wireless transmitter through the signal transmission line, and the wireless transmitter transmits the collected belt conveyor operation signal to the wireless receiver on the ship unloader, wireless After re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com