Photocatalytic internal recycle integrated MBR (Membrane Biological Reactor) reactor

A photocatalytic reactor, photocatalytic technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. Convenience and the effect of improving degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

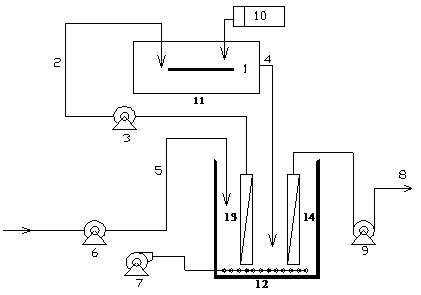

[0026] The structure of the present invention includes an ultraviolet lamp, a circulation pipe, a photocatalytic circulation pump, an overflow pipe, a water inlet pipe, a water inlet pump, a fan, a water production pipe, a water production pump, a hydrogen peroxide dosing and metering device, a photocatalytic reactor, a biochemical reactor, Photocatalytic cycle membrane module, water production membrane module.

[0027] The specific implementation process is: the sewage enters the biochemical reactor (12) through the water inlet pump (6) for biochemical degradation, the fan (7) supplies oxygen and makes the activated sludge fully contact with the wastewater, and the air bubbles generated by the aeration head The photocatalytic circulation membrane module (13) and the water production membrane module (14) are scoured to slow down membrane fouling; the photocatalysis circulation membrane module (13) is used as an internal circulation water production membrane module, which produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com