Semiconductor structure and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of product performance impact, easy oxidation of conductive pillars, etc., and shorten the manufacturing cycle and process time. , to avoid the effect of air voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

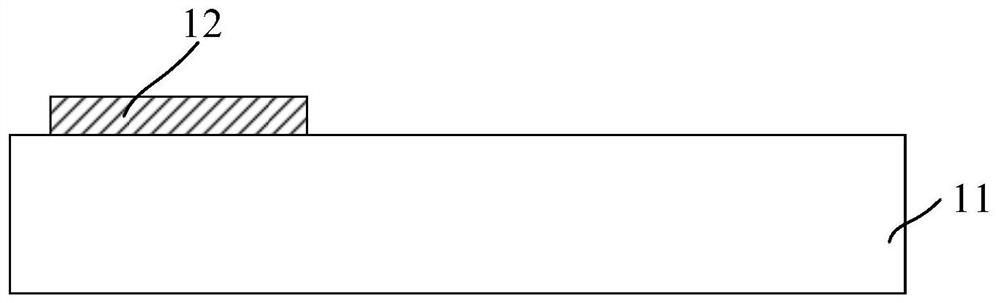

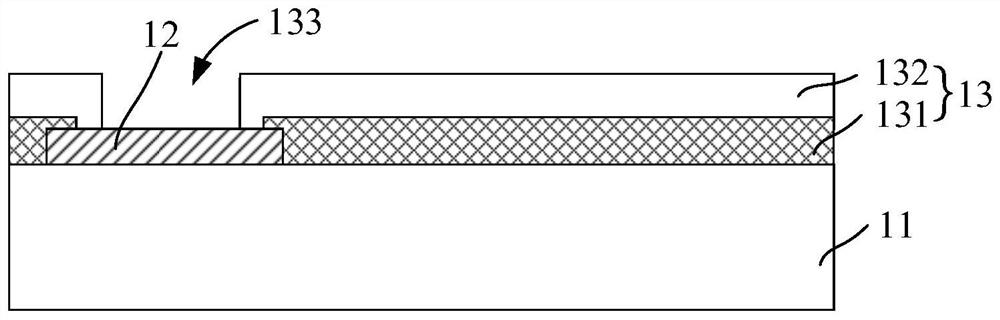

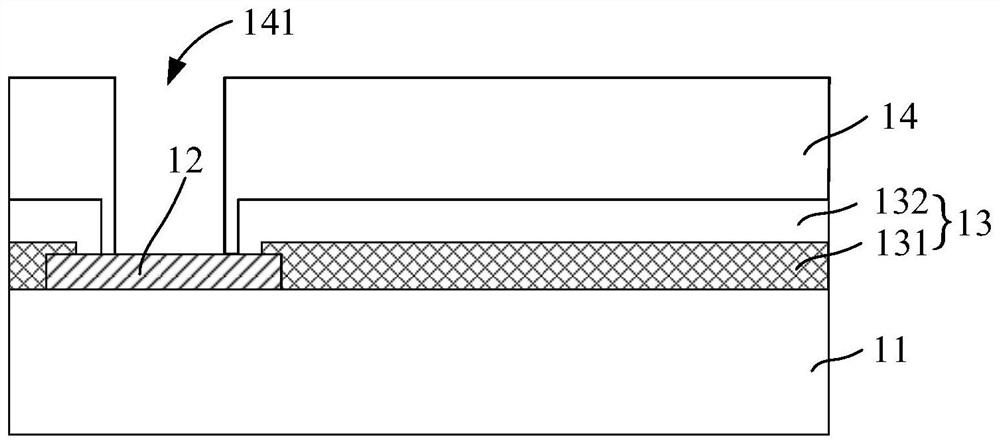

[0020] It can be seen from the background art that there is a need to provide a semiconductor structure and a manufacturing method thereof, and the semiconductor structure manufacturing method can manufacture a semiconductor structure with oxidation resistance.

[0021] In order to solve the above technical problems, an embodiment of the present invention provides a method for manufacturing a semiconductor structure, which melts the second conductive layer formed on the first conductive layer through a reflow process, so that the second conductive layer simultaneously covers the side of the first conductive layer The walls and top, in this way, help to reduce process steps and shorten the manufacturing cycle.

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, those skilled in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com