Fixing structure for automotive headlamp xenon bulb

A car headlight and fixed structure technology, which is applied in the field of vehicle lighting, can solve problems such as astigmatism, loose or rotating reflectors, and poor light concentrating, and achieve stable and reliable connection, convenient installation and replacement of lamp holders, and solve astigmatism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

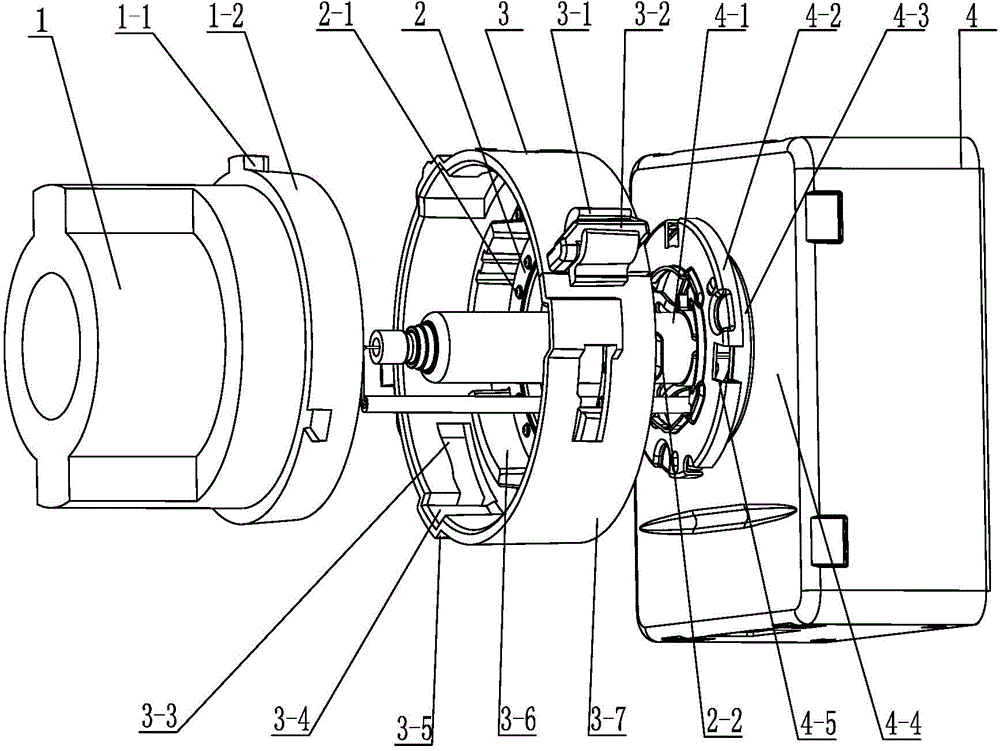

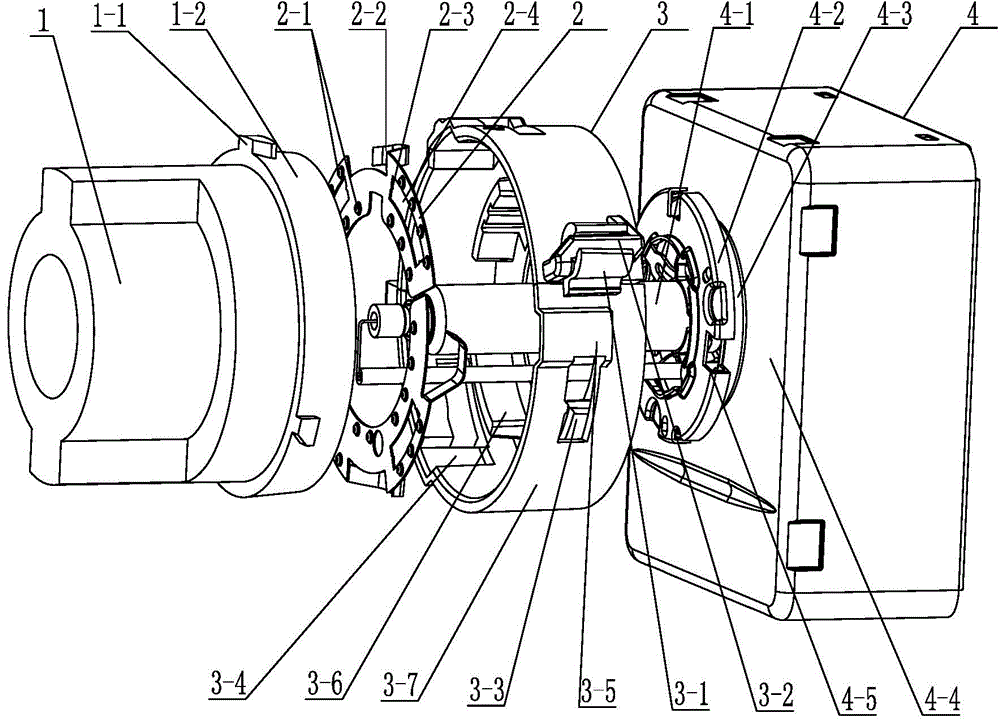

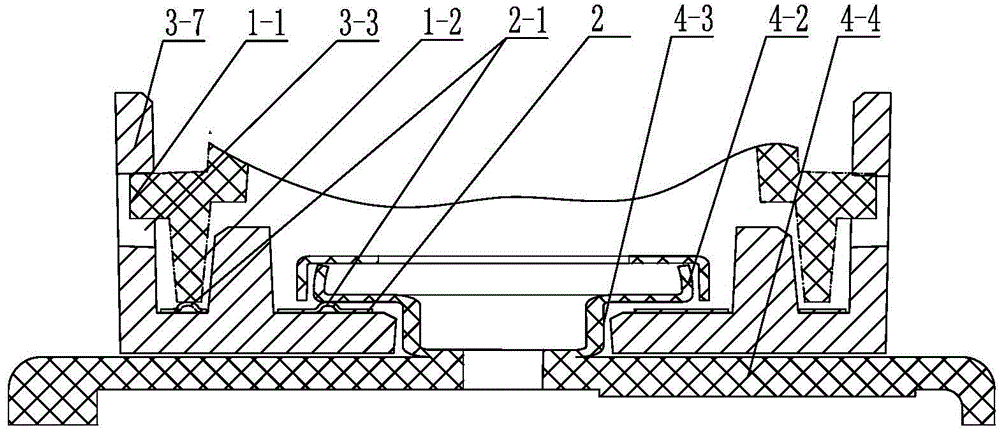

[0017] See Figure 1~3 As shown, the automobile headlamp xenon bulb fixing structure of the present invention includes a reflector 1, a bulb fixing seat 3 and a lamp holder 4 connected from top to bottom.

[0018] See Figure 1~3 As shown, the lamp holder 4 of the present invention includes a lamp housing 4-4 and a bulb 4-1 installed on the lamp housing 4-4. The upper part of the lamp housing 4-4 has a neck 4-3, and the upper part of the neck 4-3 has a The limit plate 4-2 that is greater than the size of the neck 4-3, and the limit plate 4-2 is provided with at least two limit notches 4-5, and the bulb holder 3 is pivoted by the limit plate 4-2. To limit and circumferentially.

[0019] See Figure 1~4 As shown, the bulb holder 3 of the present invention includes a semicircular seat body 3-7, each seat body 3-7 has a base plate at the bottom, and the upper part of the base plate is provided with a boss 3-6 for positioning the spring leaf 2 and a The matching limit post ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com