A connection structure between constant velocity universal joint and wheel hub and automobile

A constant velocity universal joint and connection structure technology, applied in the direction of axles, wheels, vehicle parts, etc., can solve problems such as the connection gap between the wheel hub and the constant velocity universal joint, vehicle vibration, transmission torque fluctuations, etc., to reduce production costs, Eliminates fluctuations, reduces the effect of transmitted vibration and wheel vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

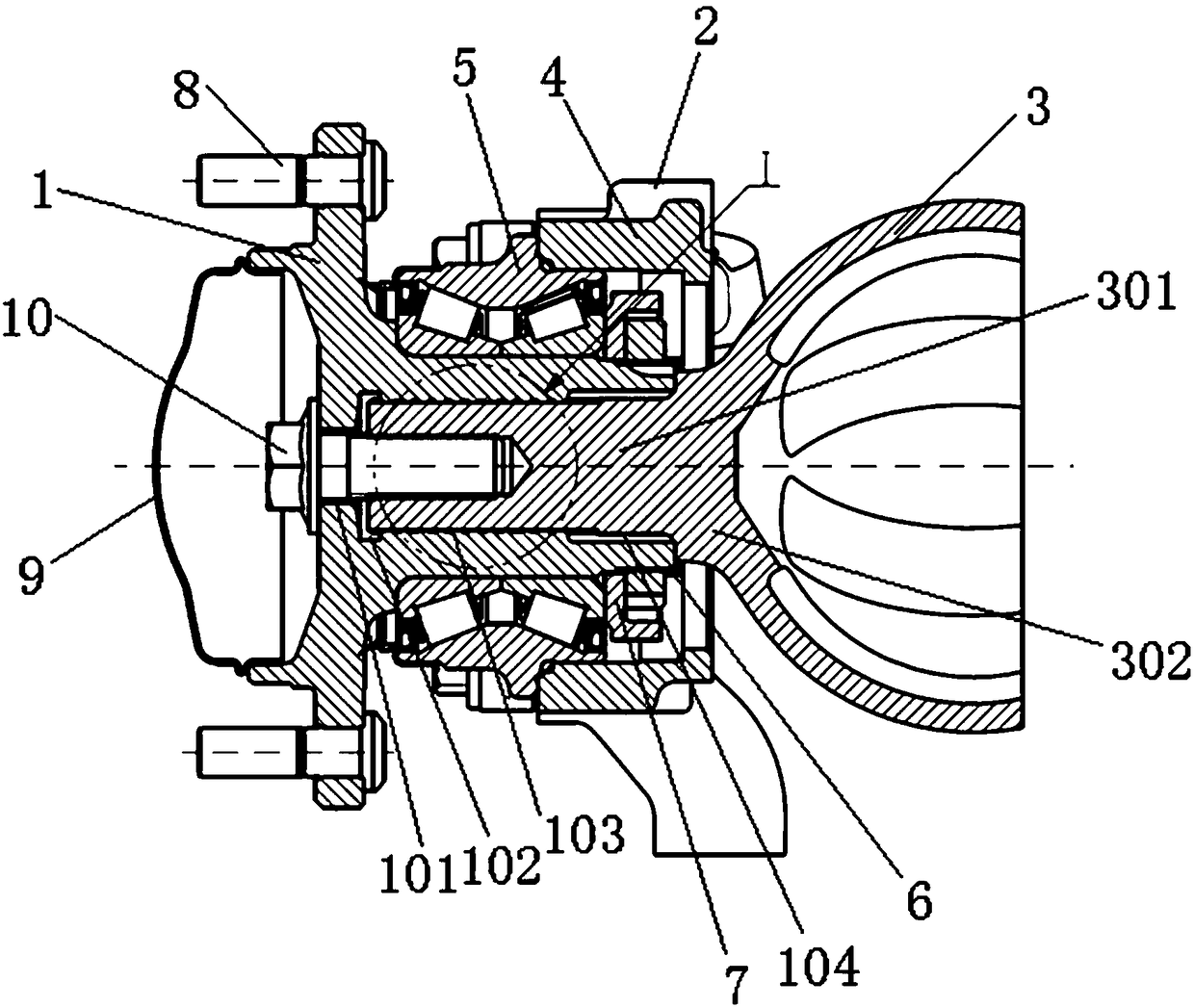

[0034] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

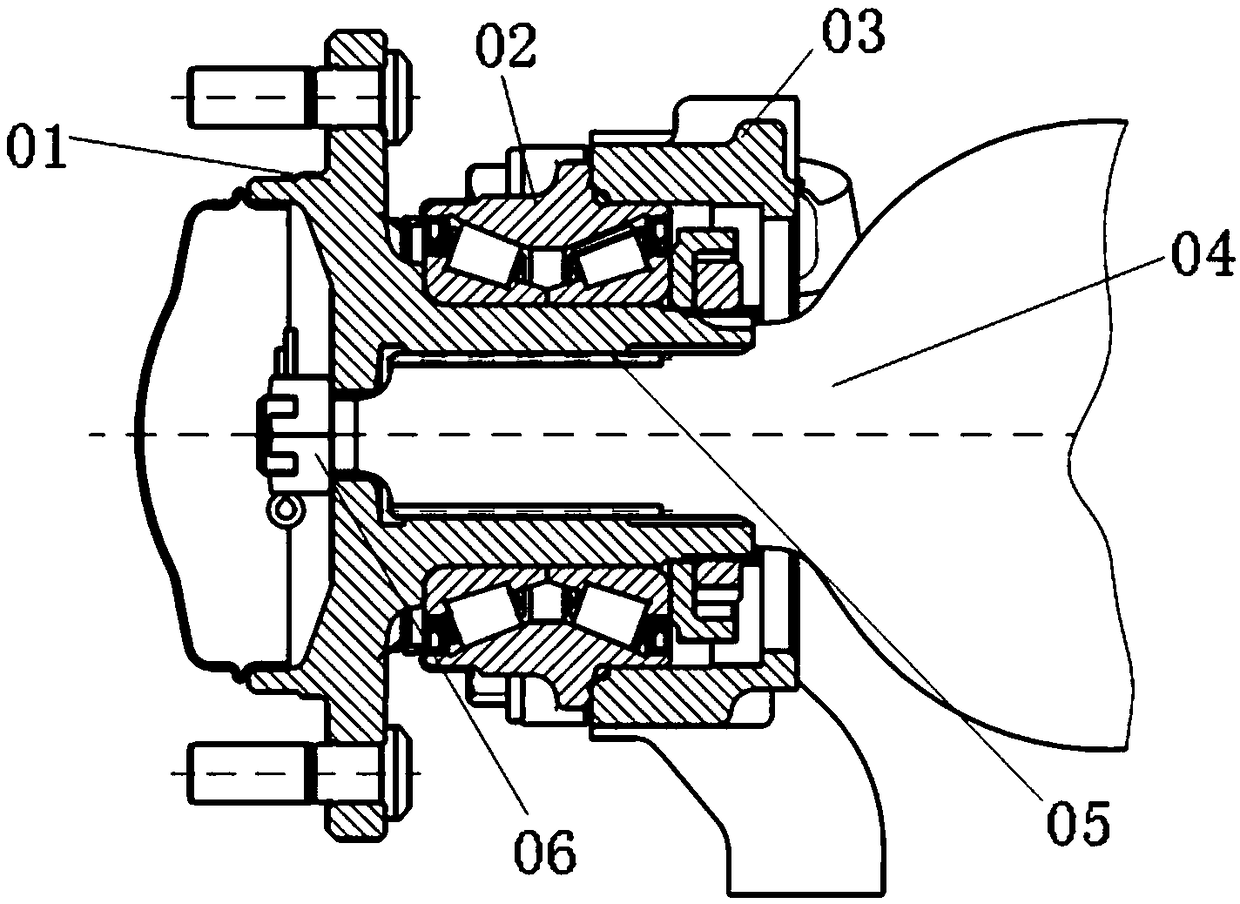

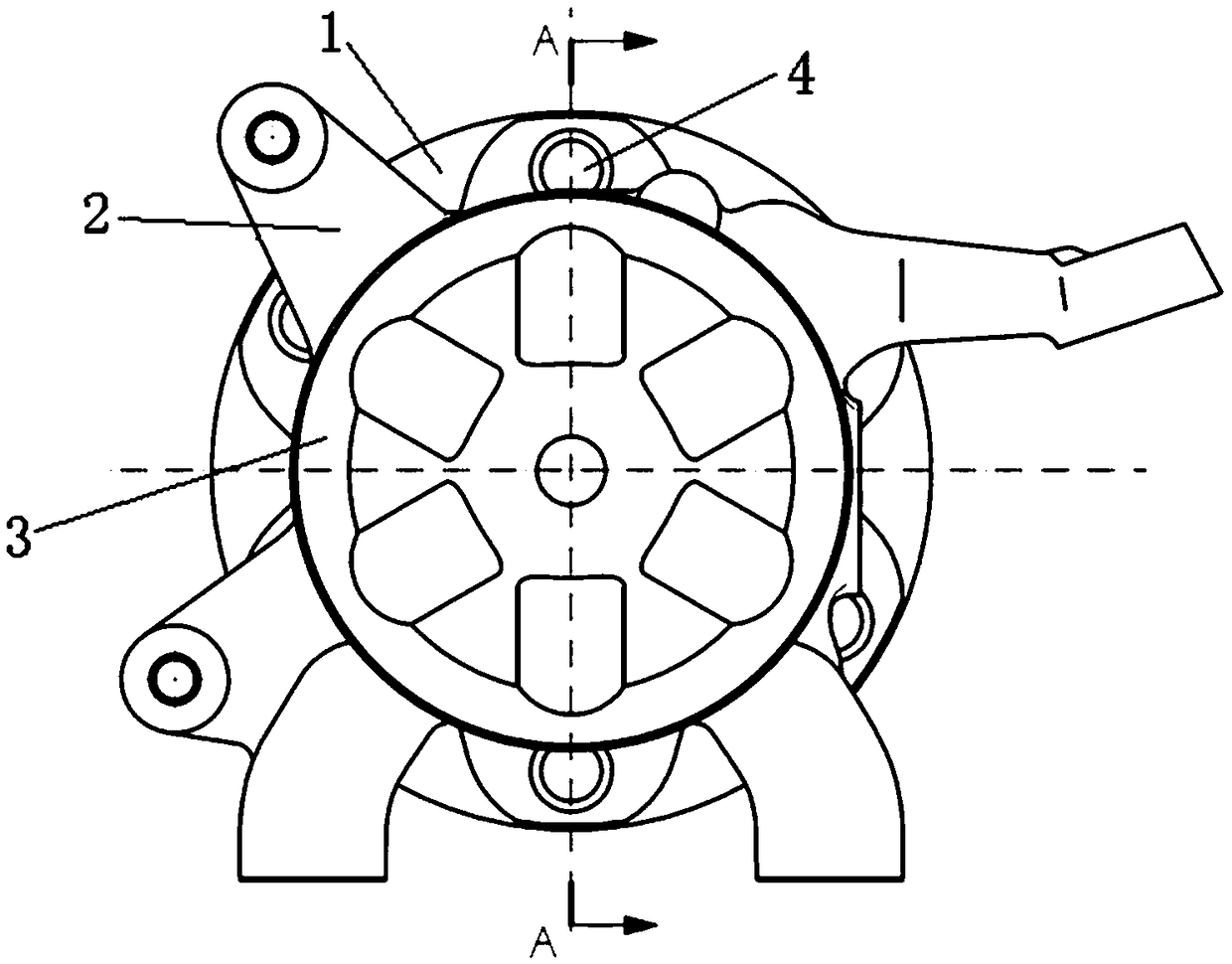

[0035] This application provides a connection structure between a constant velocity universal joint and a hub, such as Figure 2 to Figure 5 As shown, it includes hub 1, steering knuckle 2, constant velocity universal joint 3, bearing 5, bearing bolt 4, lock nut 6 and self-locking bolt 10; it also includes ABS ring gear 7 and hub cover 9.

[0036] In the technical solution, the materials used for each component are the same as those of the prior art. In this application, the so-called outer end or outer side refers to the end near the wheel, and the inner or inner end is the end opposite to the outer side or outer end.

[0037] The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com