Inside and outside flange connecting apparatus for wheel hub bearing and manufacturing method thereof

A connecting device and hub bearing technology, which is applied in the field of hub bearings, can solve problems such as difficulty in product quality assurance, axial gap, and difficult processing, and achieve the effects of easy processing, elimination of connection gaps, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

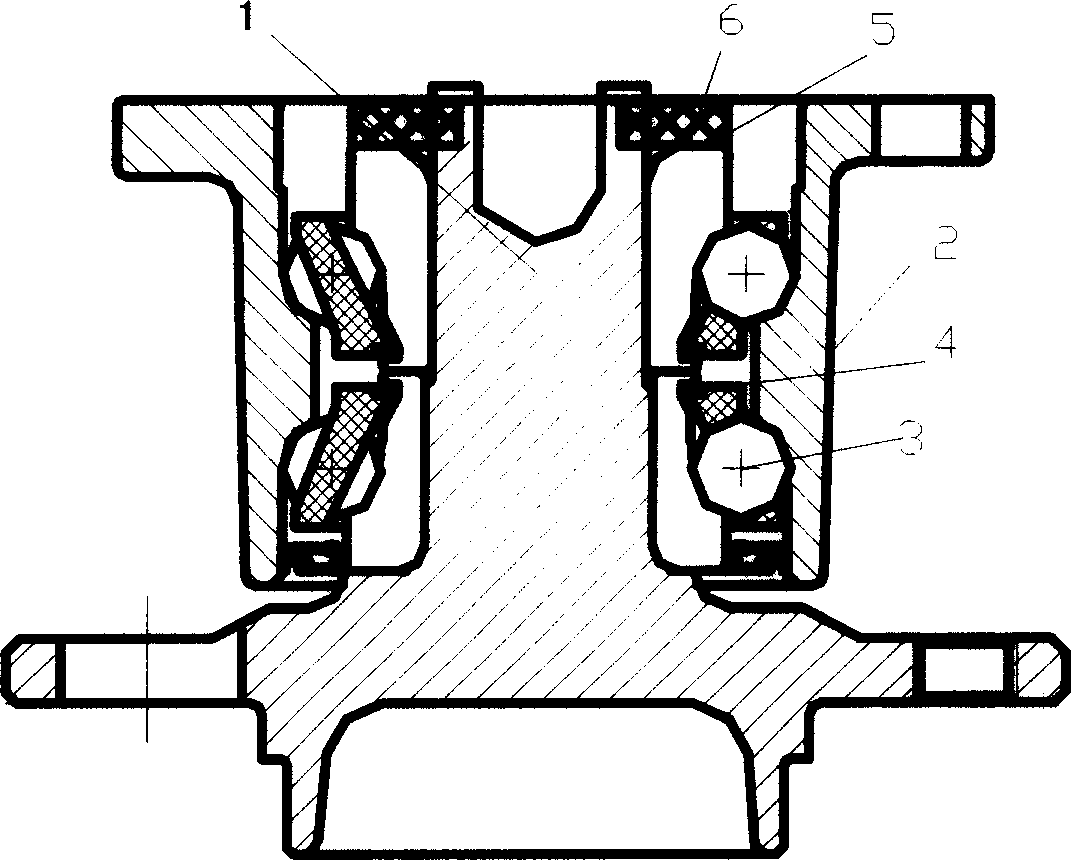

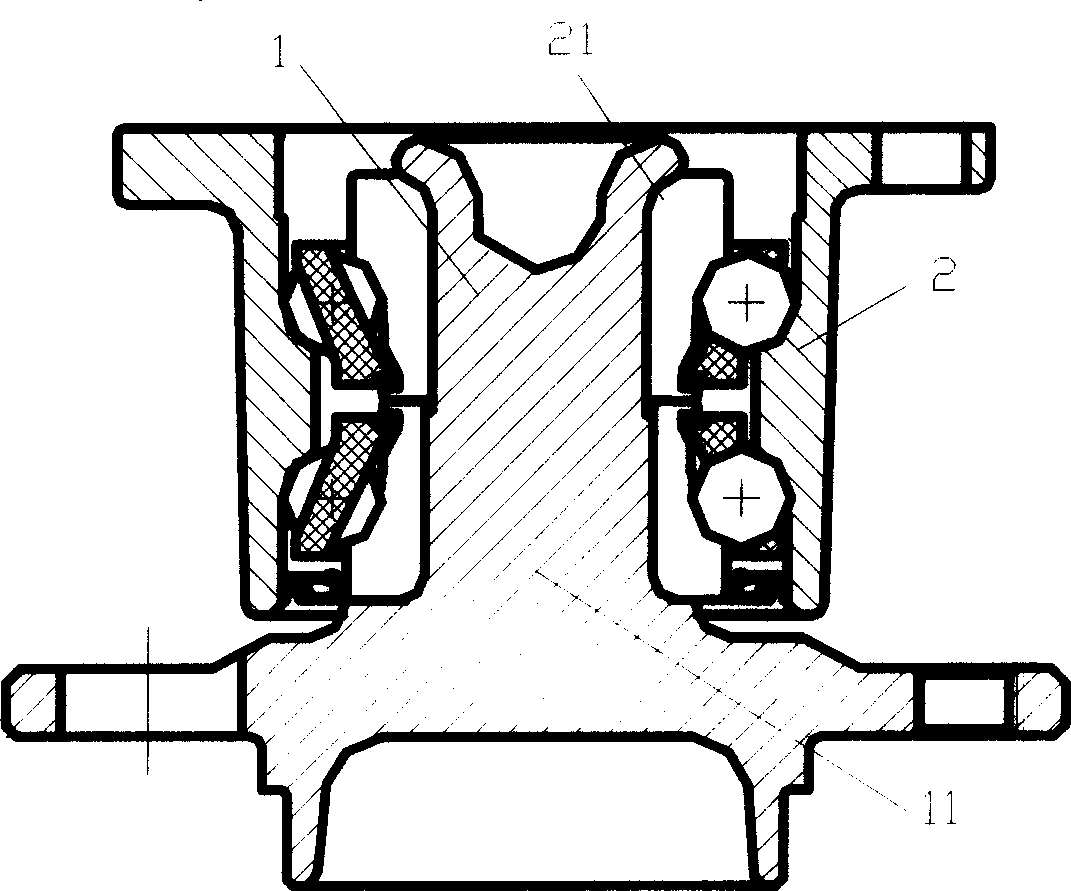

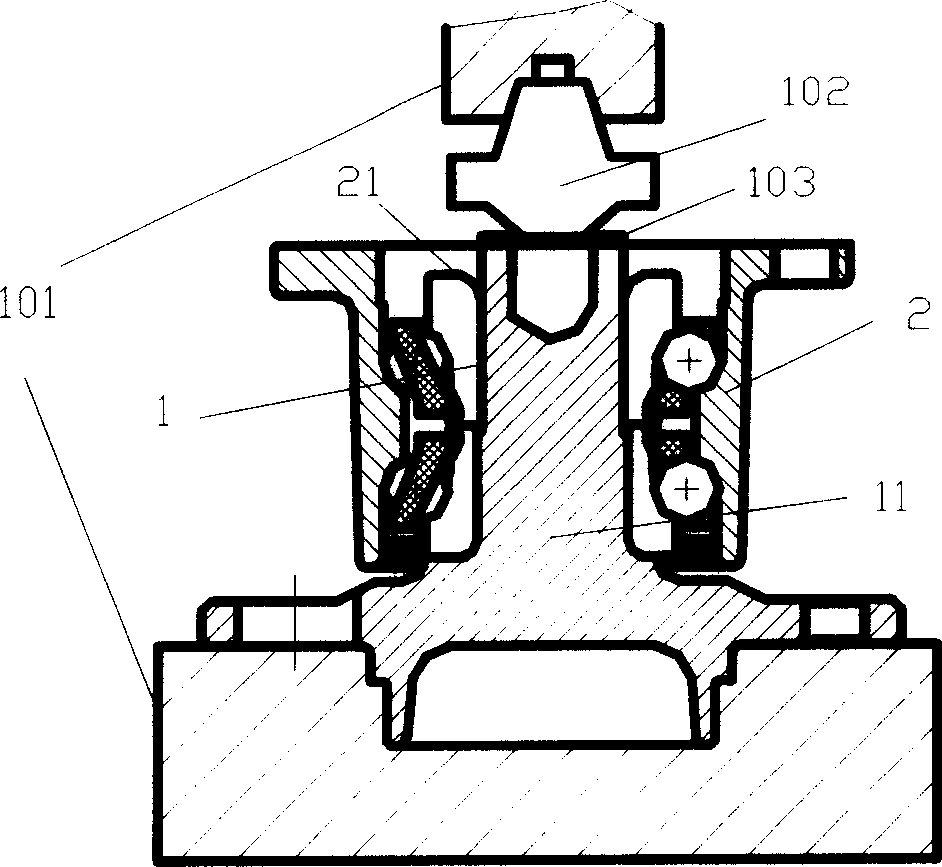

[0017] Depend on figure 2 It can be seen that the connection device of the inner and outer flanges of the hub bearing of the present invention includes an inner flange 1 and an outer flange 2 with double channels; the contact point between the outer flange 2 with double channels and the inner flange 1 It includes an inner small ring 21; the shaft 11 of the inner flange 1 is fixedly rolled with the inner small ring 21 under the action of external force;

[0018] Manufacturing method of the present invention is realized through the following steps:

[0019] Place the riveting die matching the inner flange on the inner flange;

[0020] add grease;

[0021] The pressure oscillating head of the pressure oscillating rolling machine swings around its own axis and presses down, so that the axial direction of the oscillating rolling mold gradually co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com