Hydraulic shield machine segment assembly device

A technology for segment assembly and shield machine, which is used in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of vibration of the rotary system, broken piston rod, reduced stability, etc., and achieves high fine-tuning accuracy, stable rotation, Grab convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

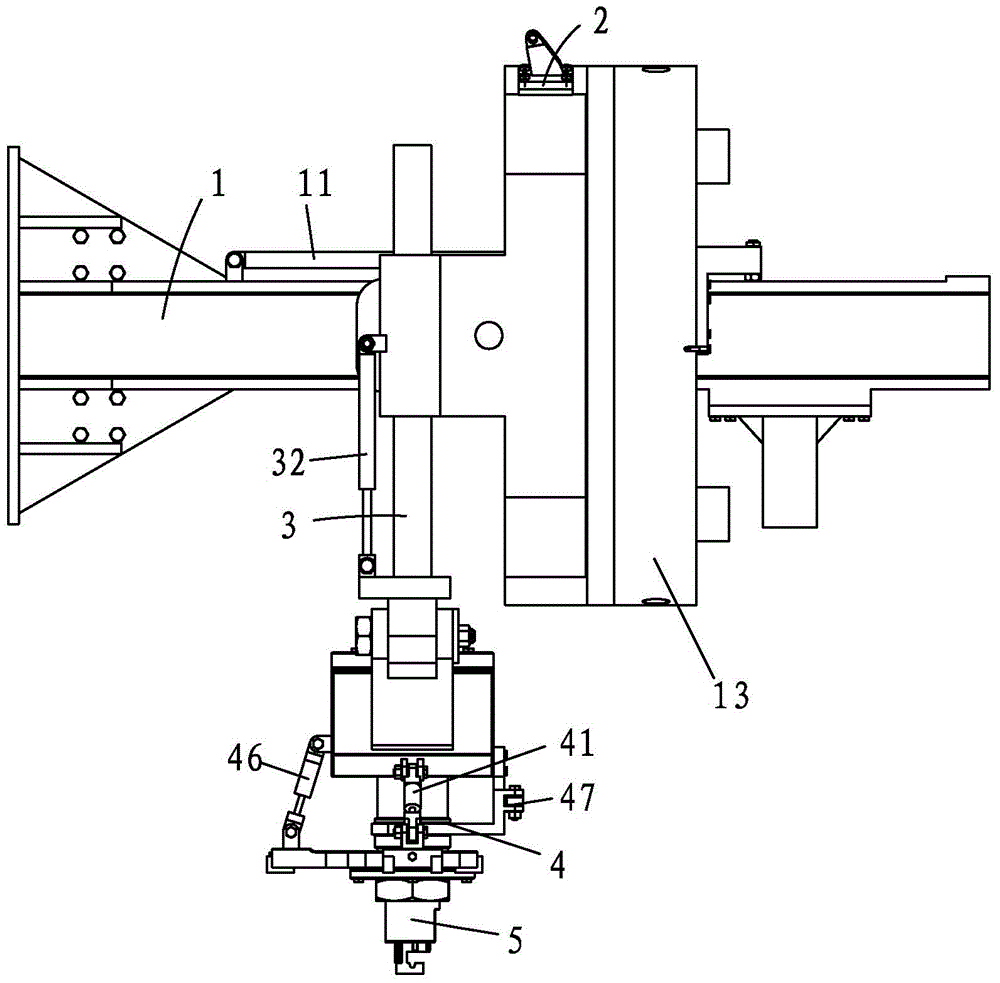

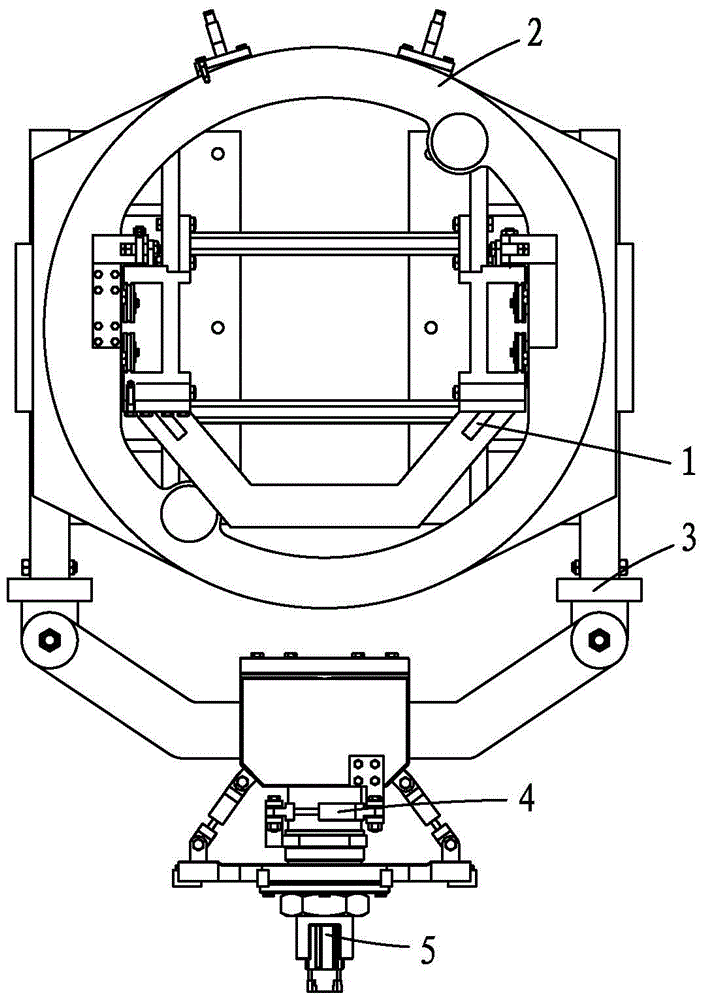

[0020] Please refer to figure 1 and figure 2 As shown, the hydraulic shield machine segment assembly device of the present invention includes a translation system 1, a rotation system 2, a lifting system 3, a fine-tuning system 4 and a gripping system 5;

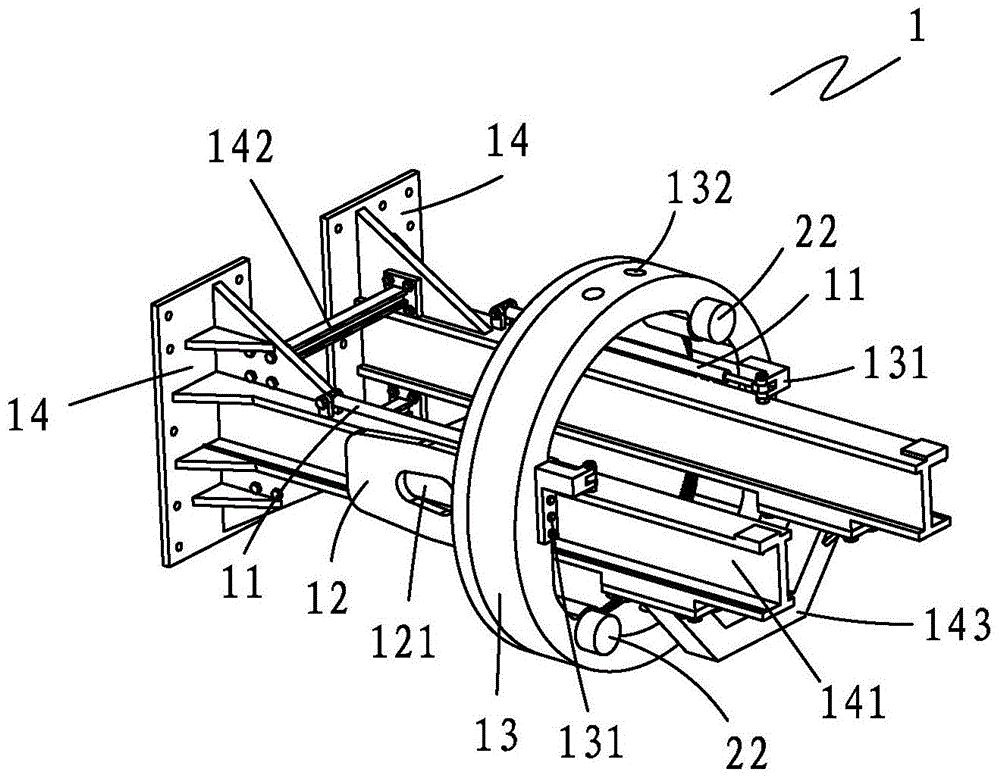

[0021] Such as image 3 As shown, the translation system 1 includes two translation cylinders 11, two roller groups 12, a moving disc body 13 and two walking beams 14; the two traveling beams 14 are arranged in parallel in a direction perpendicular to the moving disc body 13, so The two side surfaces of the walking beam 14 are provided with a walking beam guide rail 141 along a direction parallel to the walking beam 14; The moving disc body 13 is fixedly connected; the moving disc body 13 is provided with two fixed blocks 131, and the two fixed blocks 131 are L-shaped fixed blocks, and one end of the two translation oil cylinders 11 is hinged on the walking beam 14, and the other One end is hinged on the fixed block 131,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com