Voltage Dividers for High Voltage Energy Metering Devices

A metering device, high-voltage electric energy technology, applied in the direction of the voltage divider, etc., can solve the problems that the high-voltage voltage divider cannot adjust the measurement accuracy of the heat source, the influence of the linear distribution of the electric field of the two plates, and the difference in the precision of the voltage divider. Uniformity, ensuring linear distribution, and improving the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

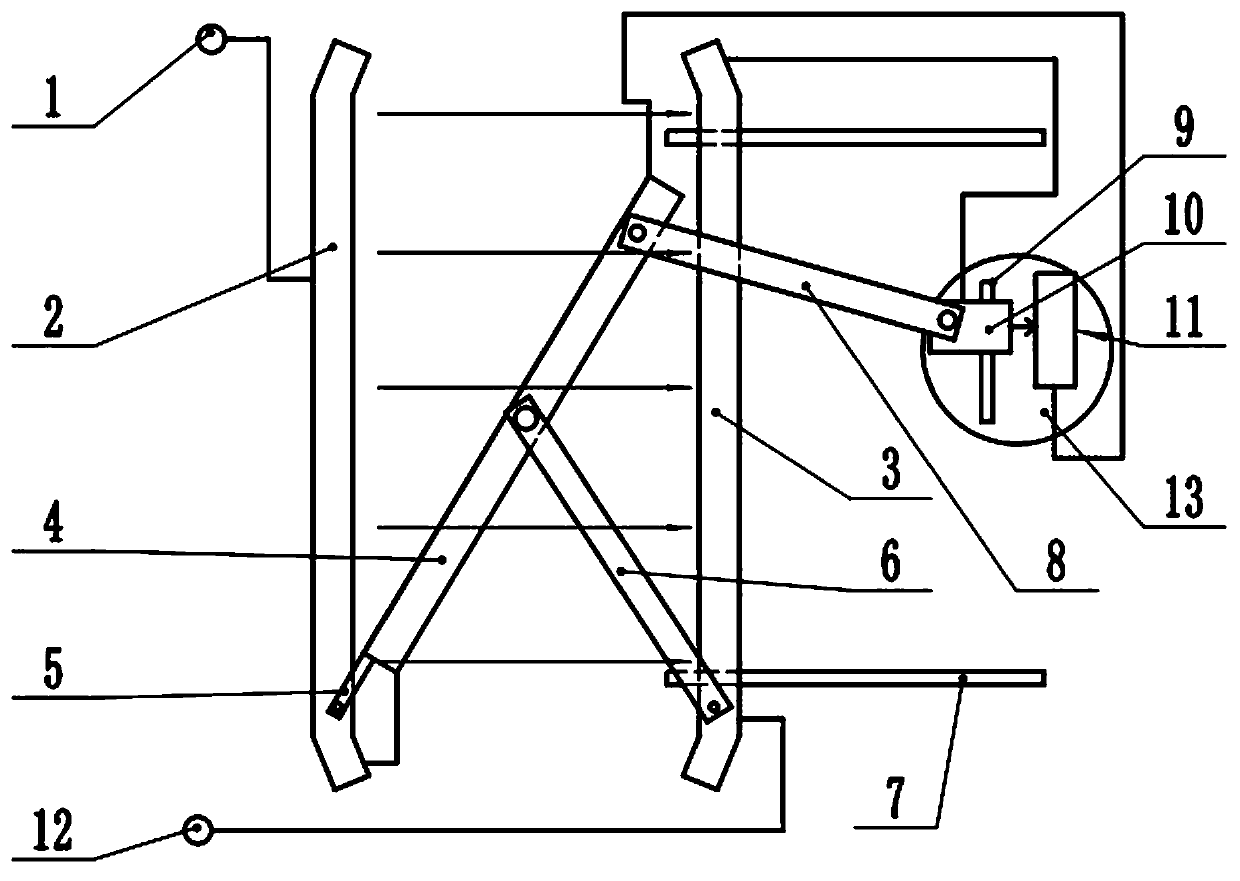

[0030] Embodiment Voltage divider for high-voltage electric energy metering device

[0031] like figure 1 As shown, this embodiment includes a first connecting terminal 1, a left pole plate 2, a right pole plate 3, a high-voltage arm resistor 4, a low-voltage arm resistor 11 and a second connecting terminal 12, and also includes a horizontal slide rail 7, a rotating bracket 5 and The strut 6 also includes a connecting rod 8 made of insulating material.

[0032] The left pole plate 2 and the right pole plate 3 are set relatively parallel, the high-voltage arm resistor 4 is plate-shaped, placed obliquely between the left pole plate 2 and the right pole plate 3, and the lower end is close to the left pole plate 2, and the upper end is close to the right pole plate 3, The lower end of the high-voltage arm resistor 4 is connected to the left pole plate 2 through a lead wire, the low-voltage arm resistor 11 includes a first pin and a second pin, the first pin is connected to the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com