Machine core for rowing machine

A rowing machine and movement technology, applied in gymnastics equipment, sports accessories, training equipment for adjusting the cardiovascular system, etc., can solve the problems of easy knotting and arrangement, easy danger, and uncontrollable resistance, so as to avoid rope out The effects of direction deviation, stable winding and winding, and consistent moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

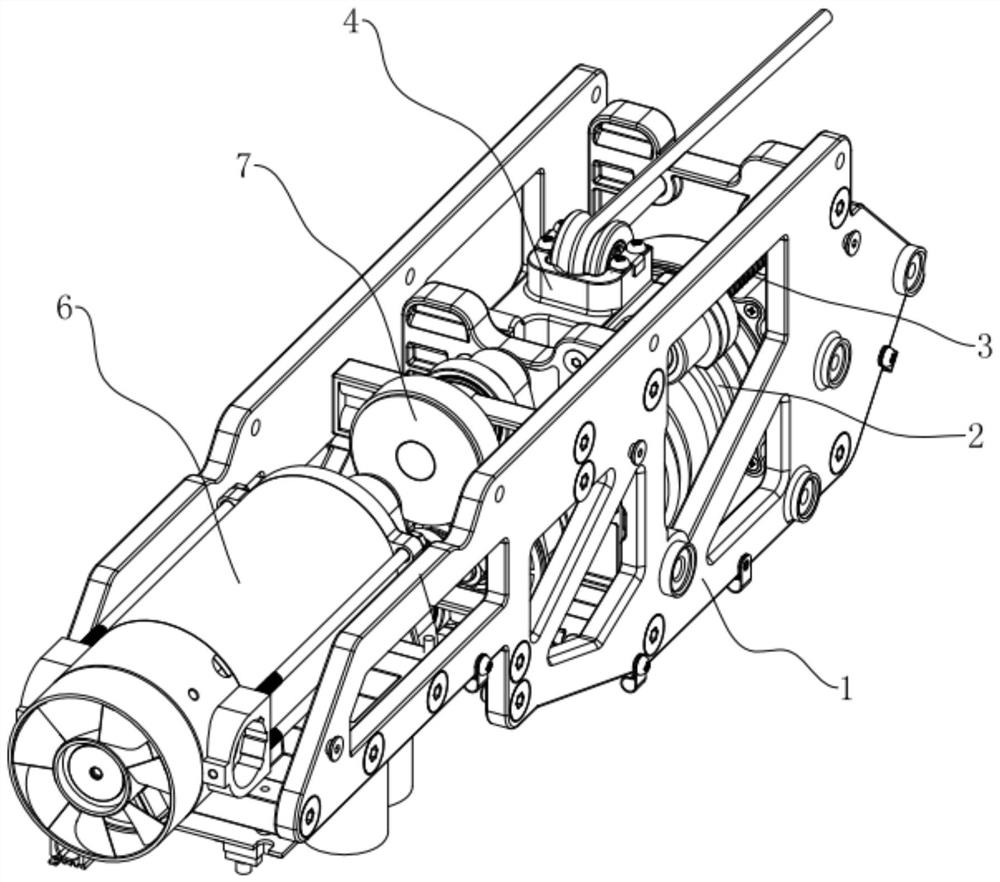

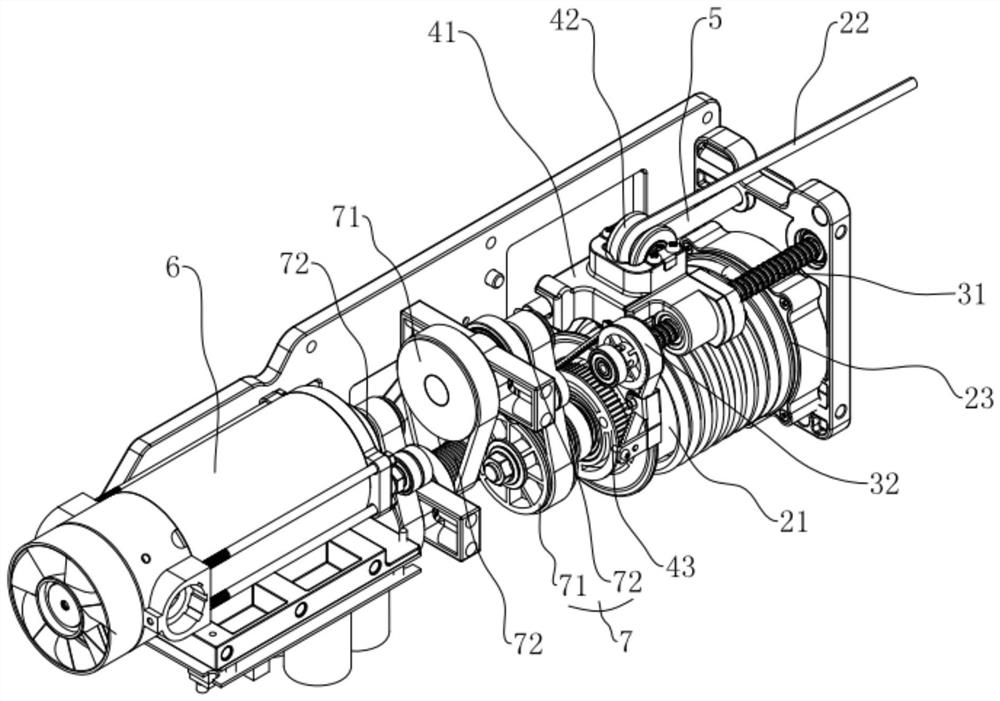

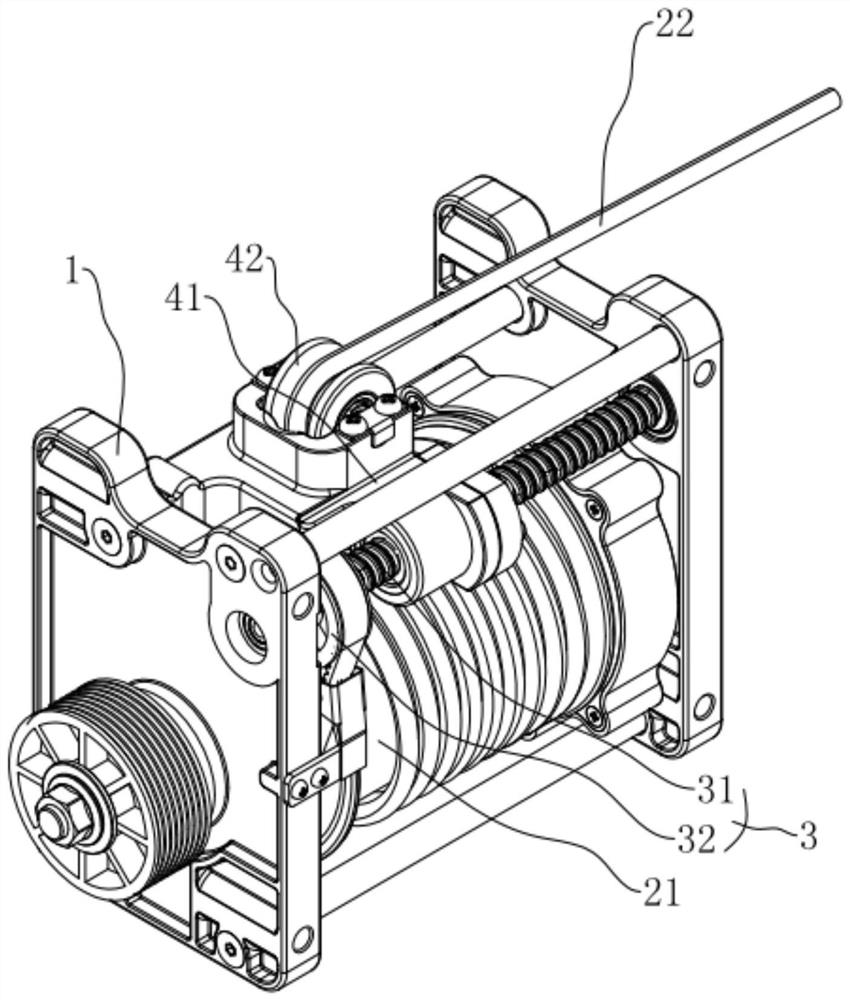

[0038] refer to Figure 1 to Figure 4 The movement for the rowing machine will be further explained.

[0039] A movement for a rowing machine, such as figure 1As shown, it includes a frame 1, a damping member 6, several groups of transmission wheel groups 7 and a winding group 2, and the damping member 6, several groups of transmission wheel groups 7 and the winding group 2 are sequentially installed on the machine along the length direction of the frame 1. on the frame 1, and the damping member 6 and the reel group 2 are respectively connected with the transmission wheel group 7 at both ends of the frame 1, so as to reduce the volume to reduce the space occupied, and make the reel group 2 rotate to drive the transmission wheel group 7 to rotate. The rotating shaft of the transmission wheel set 7 linked with the damper 6 rotates, and provides the rotation resistance of the winding group 2 through the damper 6, so that the athlete can achieve the exercise effect. In the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com