A fine-tuning device for the head of a single-point forming manipulator

A technology of a fine-tuning device and a robotic arm, which is applied in the field of sheet metal forming, can solve the problems affecting the forming quality of metal sheets and the inaccurate fine-tuning of forming tools, and achieve the effect of ensuring the forming quality and improving the fine-tuning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

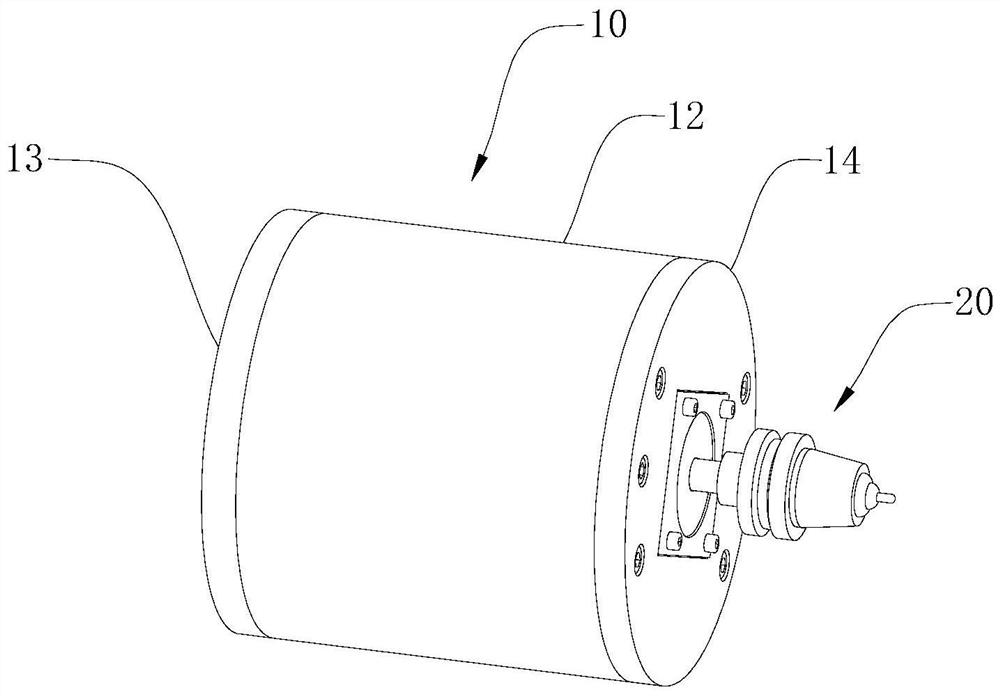

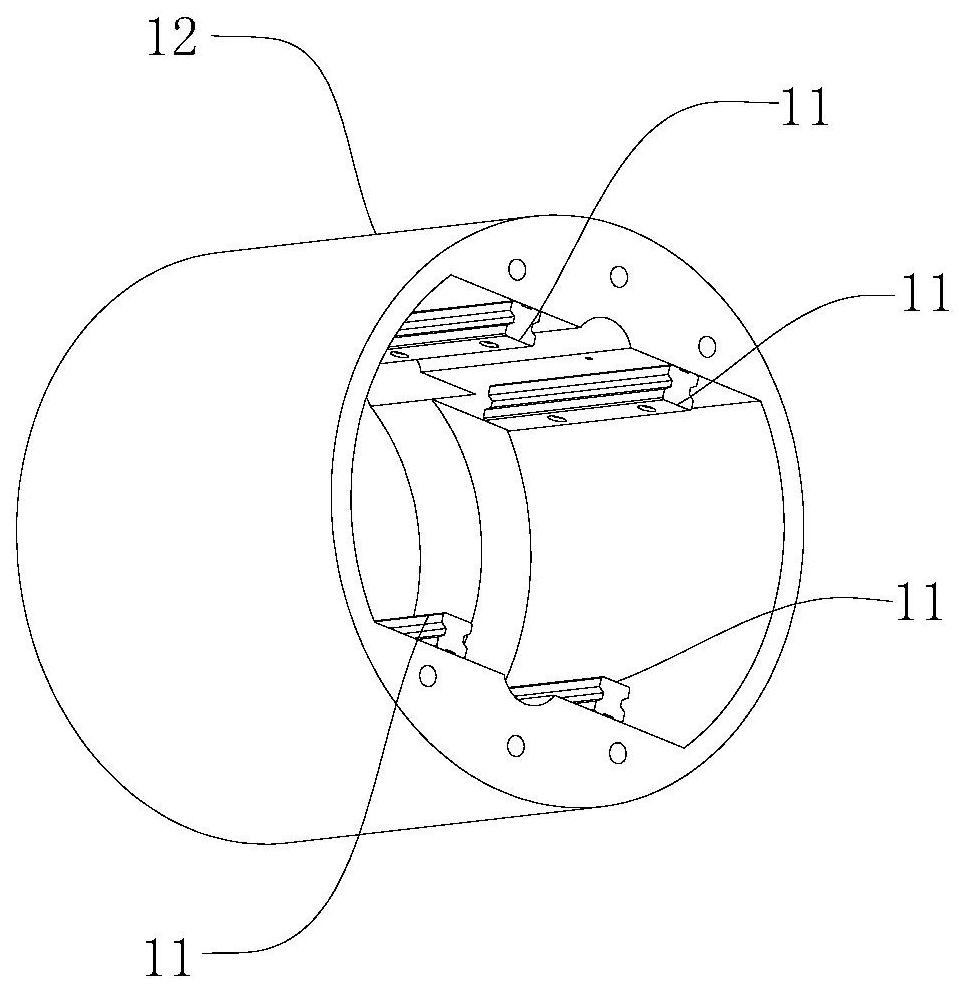

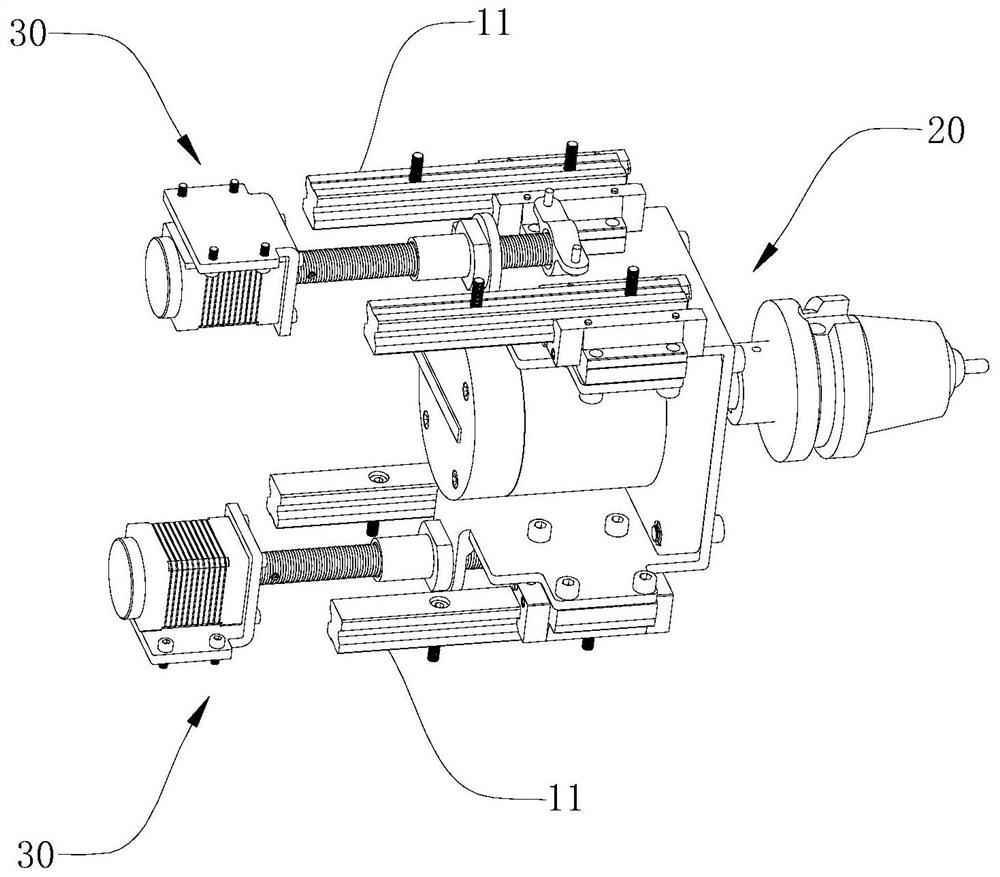

[0032] Please refer to figure 1 and 2 , a single-point forming mechanical arm head fine-tuning device, including a housing 10. The casing 10 includes a cylinder body 12 , and flanges 13 and end caps 14 respectively disposed at two ends of the cylinder body 12 . Four guide blocks 11 are installed on the inner side wall of the cylinder body 12 through bolts. The four guide blocks 11 extend in the same direction and are evenly spaced along the circumference of the cylinder body 12 . The flange 13 is connected to the barrel 12 through bolts, and is used for connecting with the mechanical arm.

[0033] Please refer to image 3 , the fine-tuning device for the head of the single-point forming mechanical arm, also includes a pressing assembly 20 and two sliding assemblies 30 . The pressing assembly 20 passes through the end cover 14 and is slidably fitted with the cylinder body 12. The two pressing assemblies 20 are connected to the corresponding two sides of the sliding assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com