Sensor beam lifting device used for deflectograph

A sensor and deflection meter technology, applied in the direction of supporting machines, balance weights, mechanical equipment, etc., can solve problems such as out-of-synchronization and easy wear of wire ropes, and achieve the effect of ensuring the adjustment effect and improving the fine-tuning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

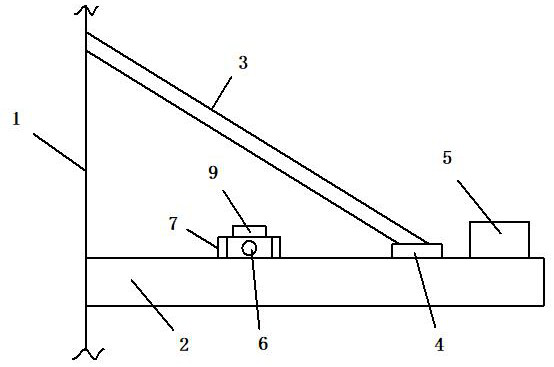

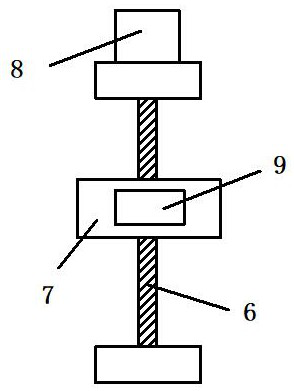

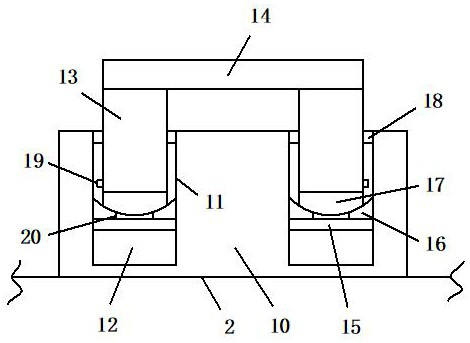

[0015] refer to Figure 1-3 , a specific embodiment of the present invention includes a bearing mechanism 1, one end of the sensor beam 2 is axially connected to the bearing mechanism 1, and a first hydraulic cylinder 3 is axially connected to the bearing mechanism 1, and the piston end of the first hydraulic cylinder 3 is connected to The device 4 is connected to the other end of the sensor beam 2, the first hydraulic cylinder 3 is located above the sensor beam 2, a three-axis gyroscope 5 is installed on the sensor beam 2, and a lead screw 6 is installed on the top surface of the sensor beam 2, and the lead screw 6 is connected to the sensor beam 2. The first hydraulic cylinder 3 is vertical, the screw 6 is equipped with a nut seat 7, the servo motor 8 is connected with the rotating nut (not shown in the figure) in the nut seat 7, and the counterweight 9 is installed on the surface of the nut seat 7, connected The device 4 includes a base 10, on which two sleeves 11 are symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com