Support tools for equipment assemble

A technology of equipment and tools, applied in the field of tools that play a supporting role in the assembly process of mechanical equipment, can solve problems such as inability to guarantee installation, instability, and unreliability, and achieve the effects of improving work efficiency, fine-tuning precision, and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

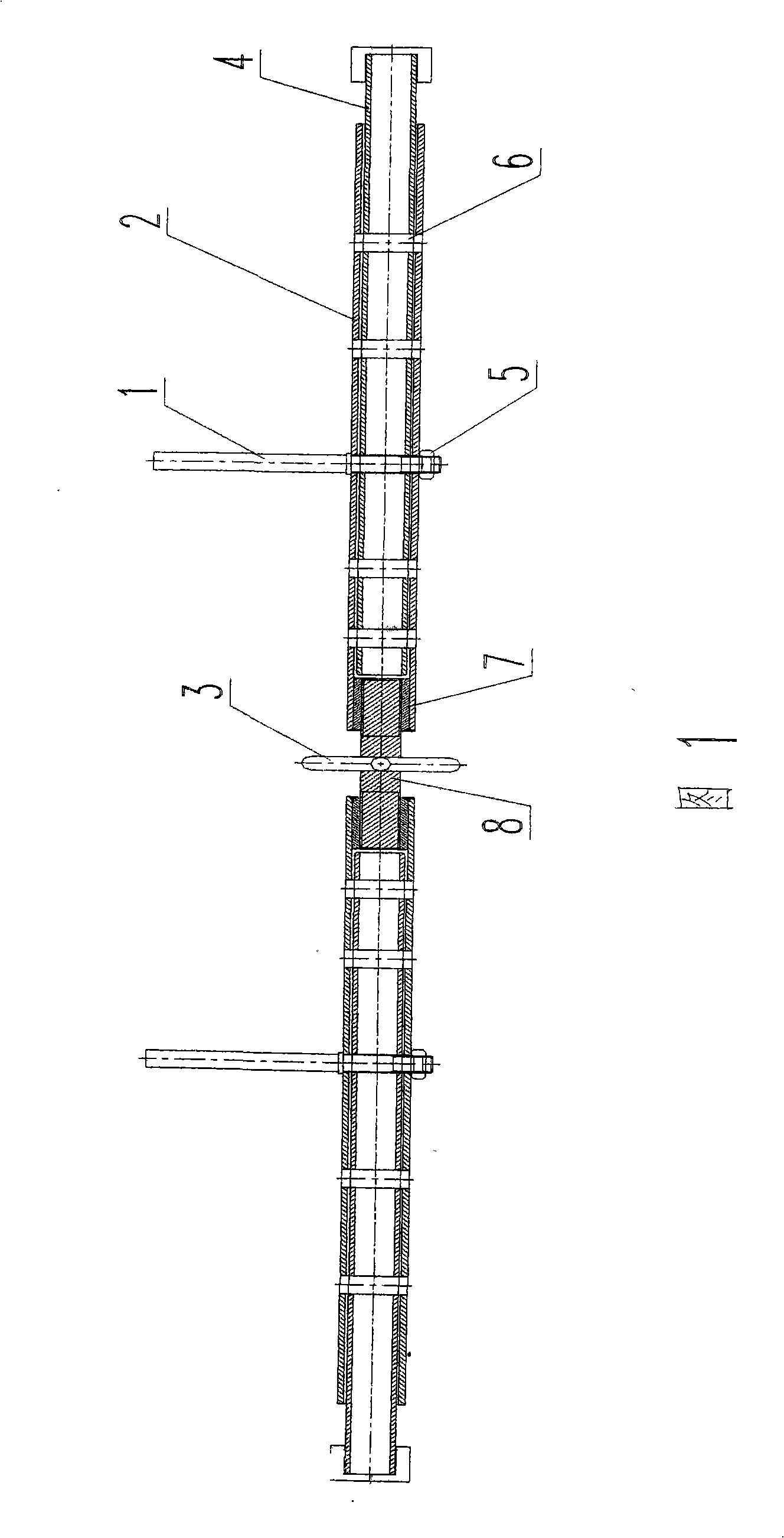

[0009] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

[0010] One embodiment of the present invention is used in the assembly work of the calender with the specification of ∮20″X600″, and is assembled according to the structure shown in the accompanying drawing. The diameter of the support tube 4 is ∮50mm, and the length is 900mm. The ends of the support tubes 4 on both sides of the whole tool are each covered with a wooden sleeve with a diameter of ∮80mm and a length of 50mm, and two steel sleeves on the left and right. The inner hole of 2 is ∮50mm, and the ends of the two sleeves 2 near the middle handwheel 3 are respectively welded with an 80mm-long threaded screw adjustment nut 7 with an internal turning M40mm and a pitch of 2mm, and are connected with the handwheel respectively. 3 The adjusting screw rods 8 in the same direction of rotation on both sides are connected in a threaded manner, and 5 pairs of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com