Hole pitch error correction system for numerical control multi-spindle deep hole drilling machine

A technology of error correction and deep hole drilling machine, which is applied in drilling/drilling equipment, parts of boring machine/drilling machine, measurement of positioning in boring machine/drilling machine, etc. Accuracy and cumulative accuracy, multi-axis deep hole drilling machine hole spacing accuracy is not high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

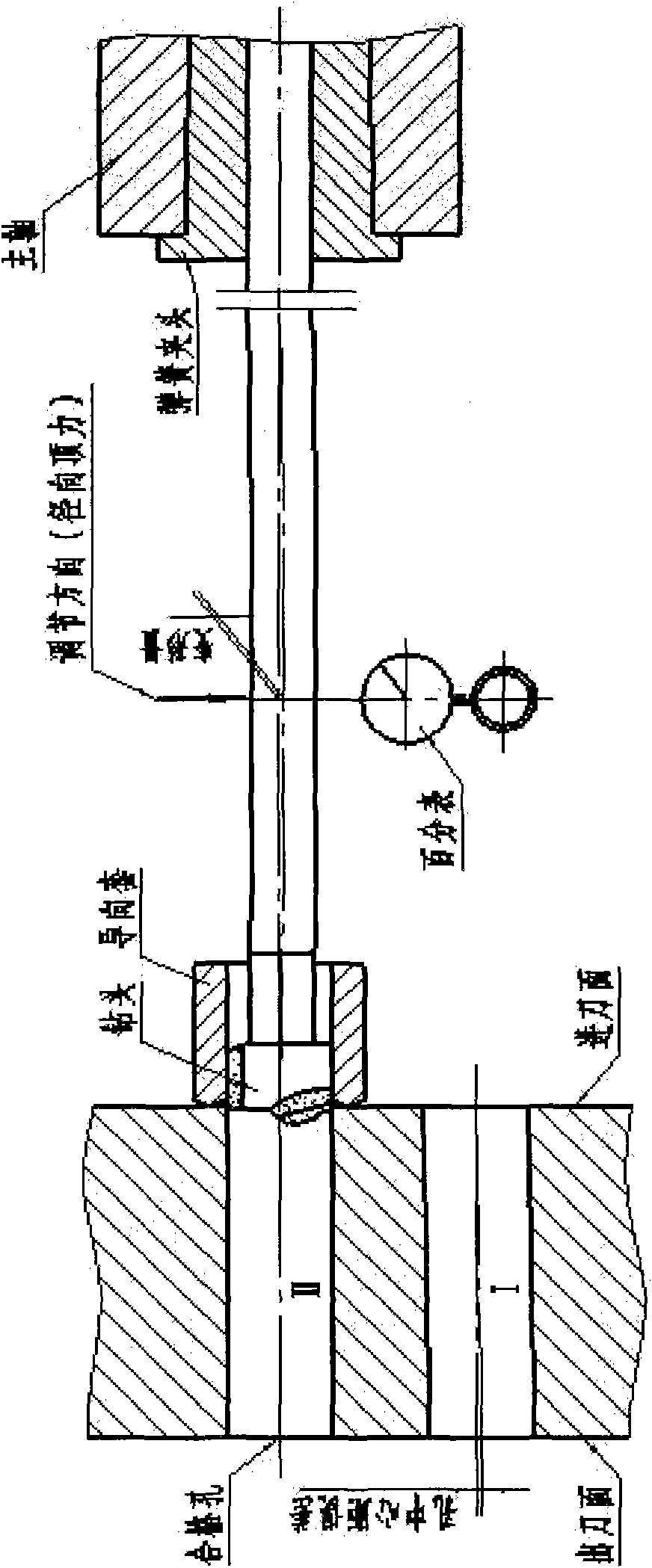

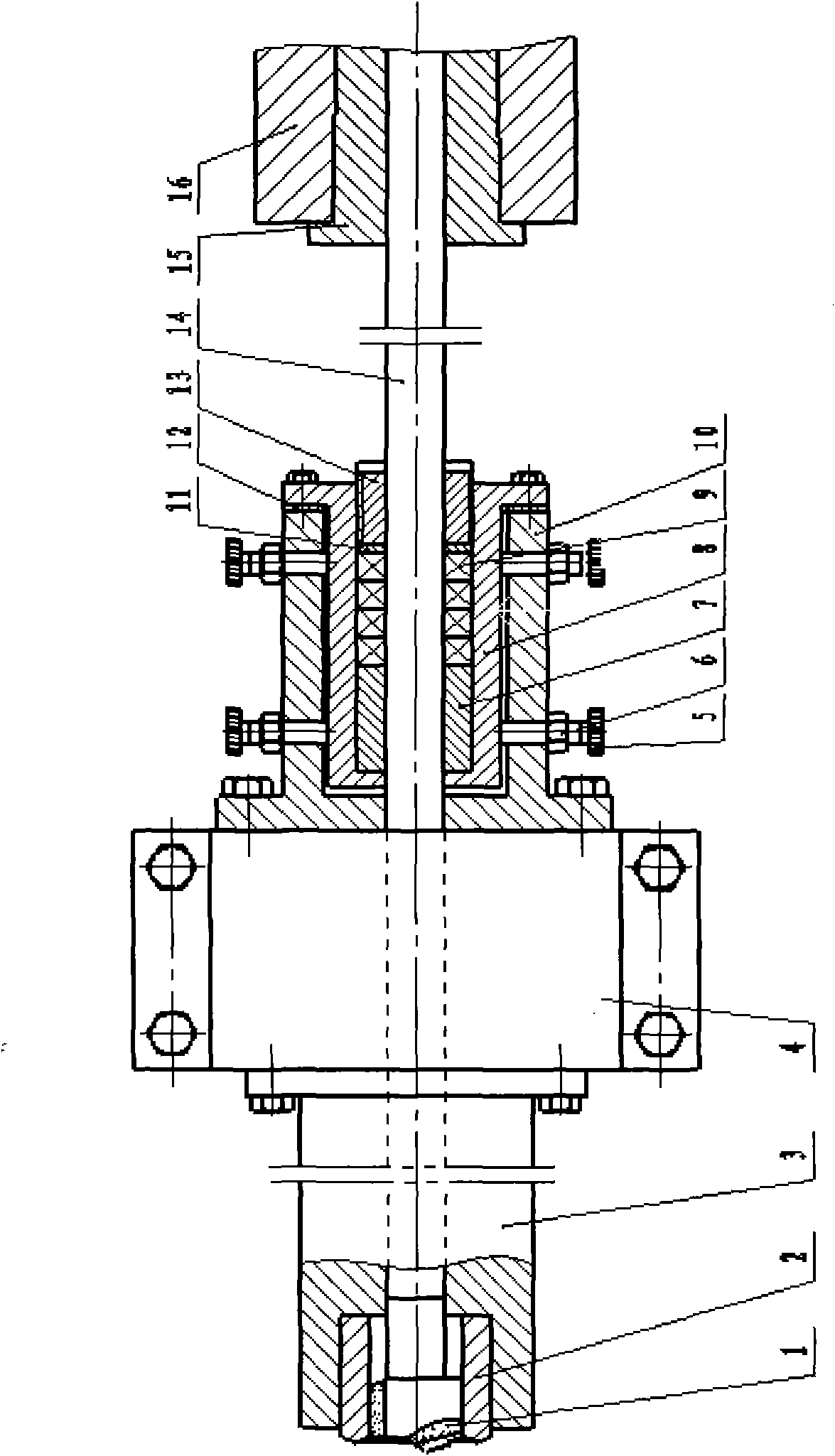

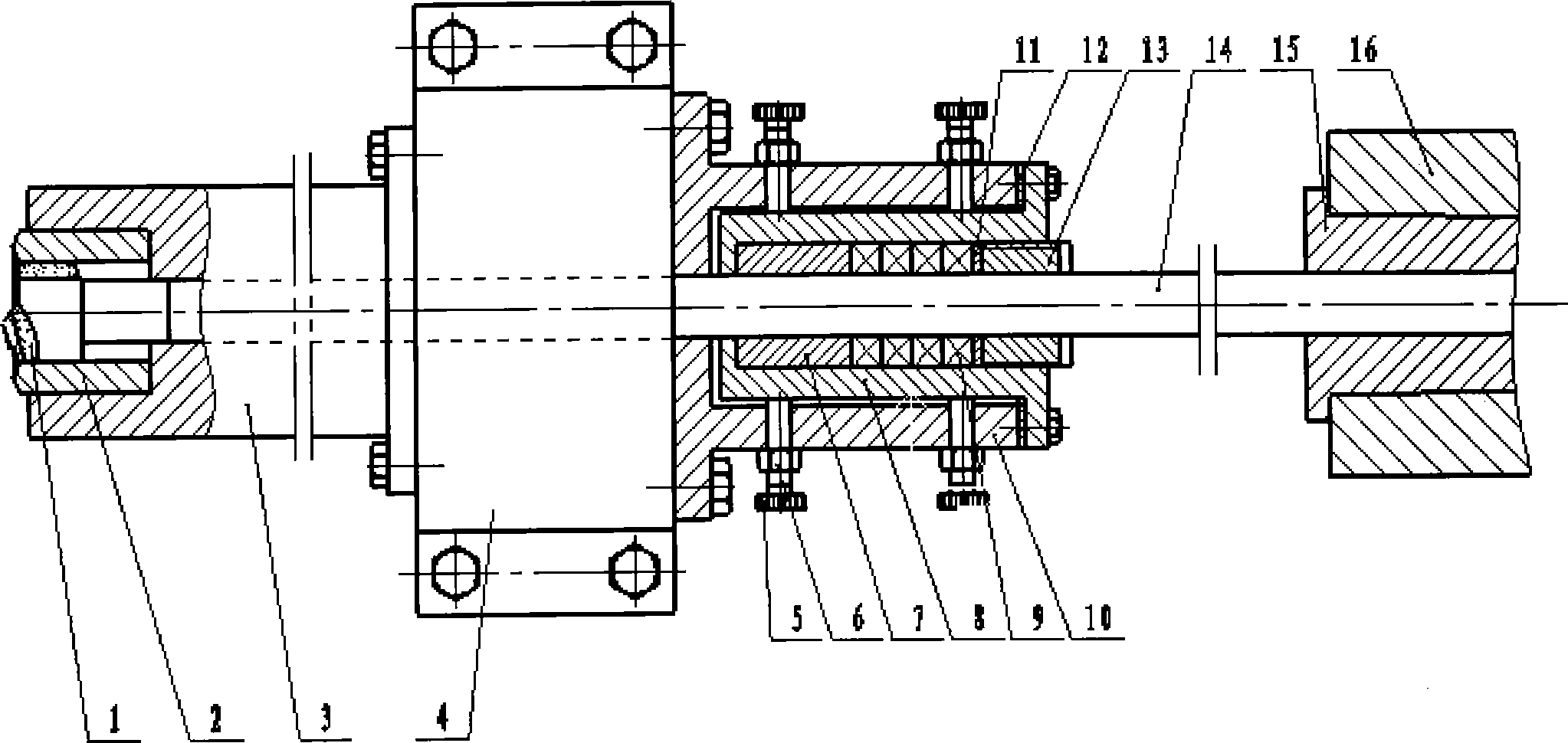

[0007] like figure 1 Shown: When the force of the fine-tuning screw acts on the drill pipe, the drill pipe will produce a slight downward bending elastic deformation. The position inside the sleeve should have a slight offset from the original position. When the drill moves axially to the exit surface of the workpiece, the offset just compensates the error value of the distance between the exit surface and the hole. In fixed jacket 10 [see figure 2 〕There are 4 or 8 fine-tuning screws evenly distributed on the circumference, and one or two rows are arranged according to the size of the drill pipe (that is, the aperture). The use of any fine-tuning screw and its force should be based on the hole distance error and the offset direction To decide.

[0008] like figure 2 As shown, the clamp body 4 fixed on the guide rail of the machine tool is fixed on the left end of the long sleeve 3 and the guide sleeve 2; the right end is fixed on the outer sleeve 10, 4 or 8 fine-tuning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com