Fine adjustment device for slide block of four-column overhead oil cylinder press

A technology of fine-tuning devices and presses, applied to presses, manufacturing tools, etc., can solve problems such as troublesome adjustments, and achieve the effects of simple and convenient adjustments, high fine-tuning precision, and reduced peak deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

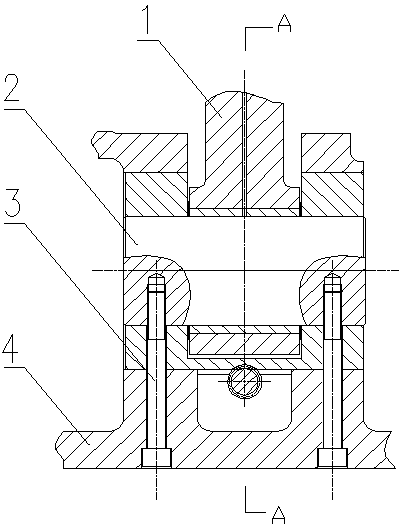

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings.

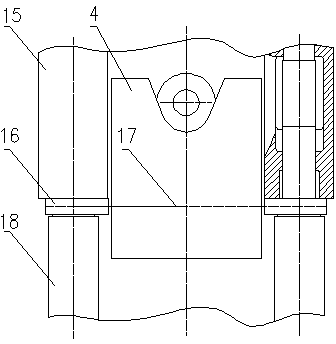

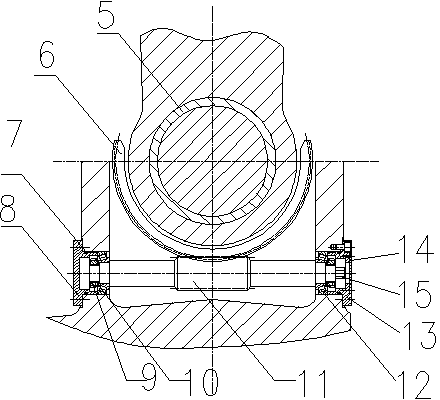

[0018] Such as figure 2 , 3 As shown in the figure, in the slider fine-tuning device of the four-column overhead oil cylinder press, two single-row tapered roller bearings 12 are installed at both ends of the worm 11 and locked with round nuts 9 and stop washers 10 respectively, and the two single-row tapered roller bearings The sub-bearing 12 is installed on the slide block 4, and the two ends are fixed with the first gland 8 and the second gland 13 respectively.

[0019] O-rings 7 are respectively embedded on the cylindrical surfaces of the first gland 8 and the second gland 13 to prevent the leakage of bearing lubricating oil.

[0020] The outside of the second gland 13 is equipped with a protective cover 14 to prevent misoperation at ordinary times, and can be removed when fine-tuning is required.

[0021] The eccentric worm gear 6 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com