Annular speed-increasing cyclone for vertical well

A cyclone and annulus technology, which is applied in the field of annular speed-increasing cyclones for vertical wells, can solve the problems of reducing drilling timeliness, prolonging the construction period, encountering obstacles and jamming, etc., achieving simple and fast maintenance and realizing environmental protection. The effect of speeding up the air swirl and increasing the radius of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

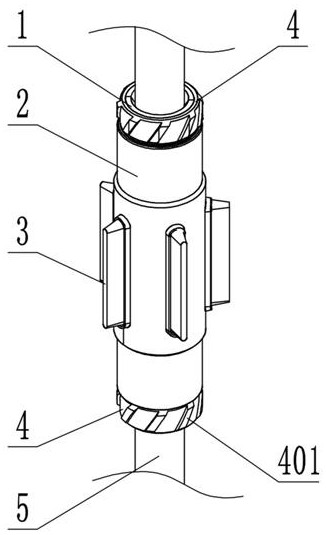

[0036] see Figure 1 to Figure 6 As shown, an annular speed-increasing cyclone for vertical wells includes an inner cylinder 1 , a rubber impeller 3 and an outer cylinder 2 .

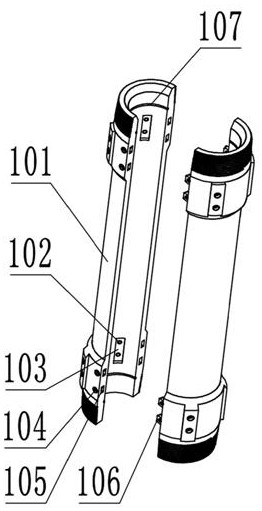

[0037] The inner cylinder 1 is composed of two detachably connected half cylinders 101. The structure of the detachable connection can be that on the opposite end faces of the two half cylinders 101, a group of mutually matching key protrusions 106 and The keyway 105 , the key protrusion 106 and the keyway 105 are correspondingly provided with a pin hole 104 , and a pin is installed in the pin hole 104 .

[0038] In addition, an internal thread can also be provided in the pin hole 104, and the pin is provided with an external thread that matches the pin hole 104. After the pin is matched with the pin hole 104, the assembled inner cylinder 1 is more firm.

[0039] The middle part of the inner cylinder body 1 is waist-shaped and forms a groove for a rubber bucket 301. The upper and lower ends of the inne...

Embodiment 2

[0049] This embodiment is further optimized on the basis of Embodiment 1, specifically:

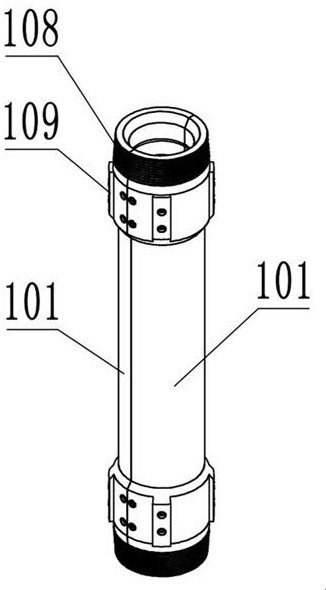

[0050] The outer wall of the inner cylinder 1 is provided with a positioning protrusion 109, and the inner wall of the outer cylinder is provided with a longitudinal positioning groove 202 adapted to the positioning protrusion 109, wherein there can be two positioning protrusions 109, and they are distributed on the outer wall of the inner cylinder 1. Upper and lower ends.

[0051] Through the cooperation of the positioning protrusion 109 and the positioning groove 202, the stability of the synchronous rotation after the assembly of the outer cylinder 2, the inner cylinder 1, and the rubber impeller 3 is further improved, thereby changing the fluid flow state of the annular space during work and increasing the fluid flow rate , to realize the speed-up of annular swirl.

Embodiment 3

[0053] This embodiment is further optimized on the basis of Embodiment 1, specifically:

[0054] A threaded hole 102 penetrating through the inner cylinder 1 is provided in the jaw groove 103 of the pliers, and a top screw is threaded in the threaded hole 102 .

[0055] By rotating and adjusting the jackscrew, the jaws 110 can be forced to stick more tightly to the drill pipe 5, so that the inner cylinder body 1 and the drill pipe 5 can be fixed more firmly by using the inner tooth surface of the jaws 110 to bite the drill pipe 5 together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com