Yarn Winder

A winding device, a technology for sliver, used in transportation and packaging, folding thin materials, transporting filamentous materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the present invention will be described in detail with reference to the drawings illustrating a first embodiment of the present invention.

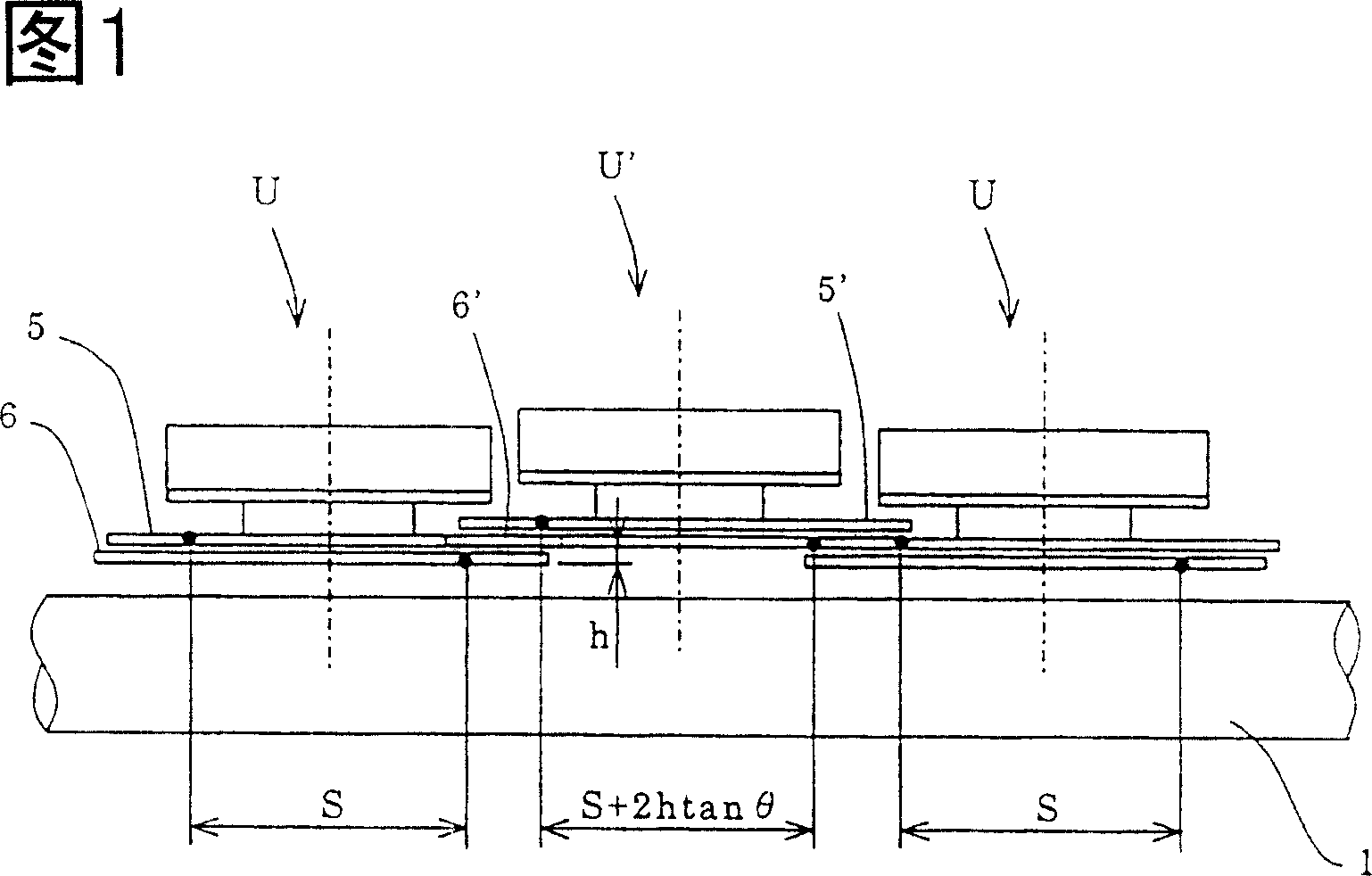

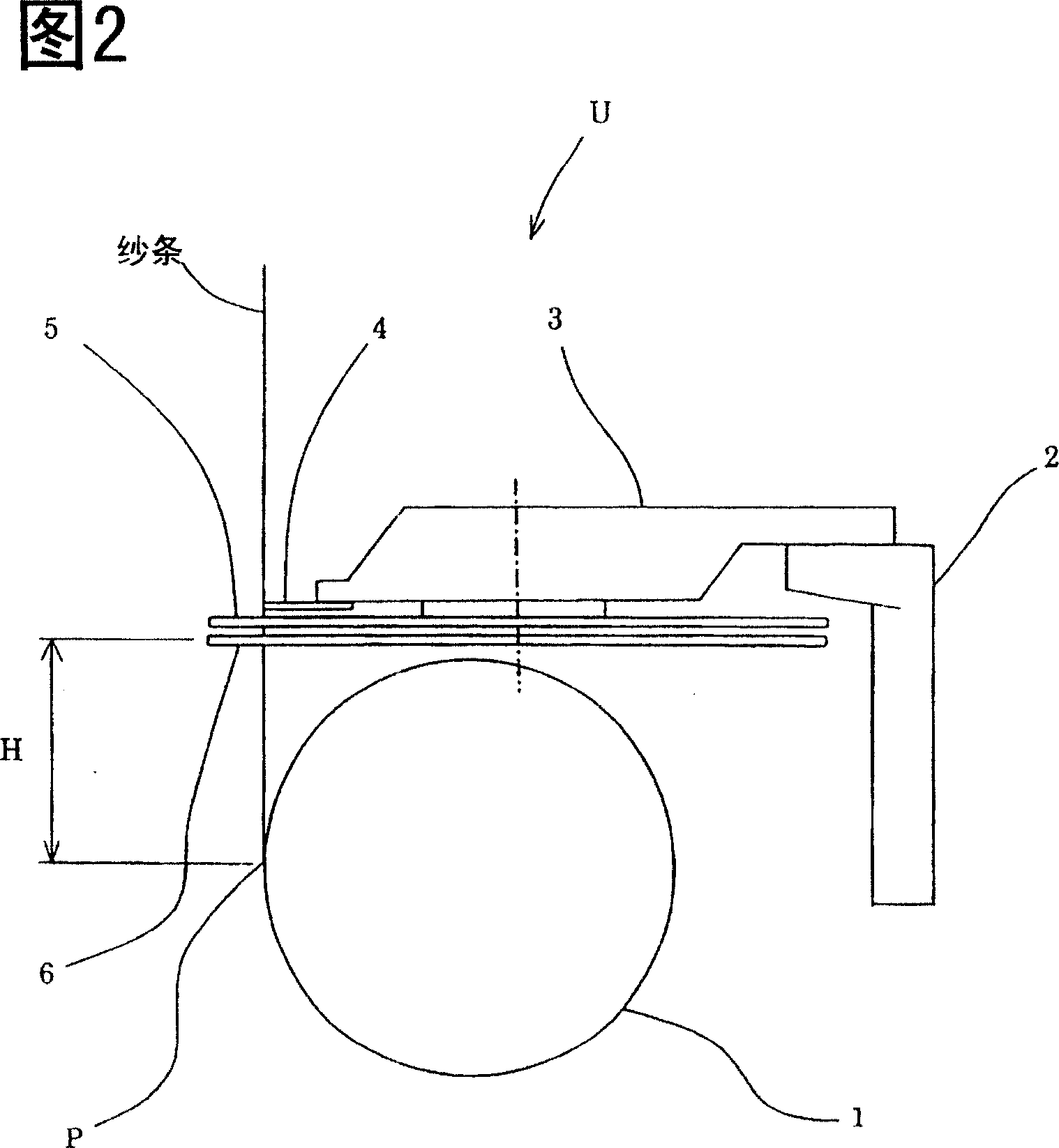

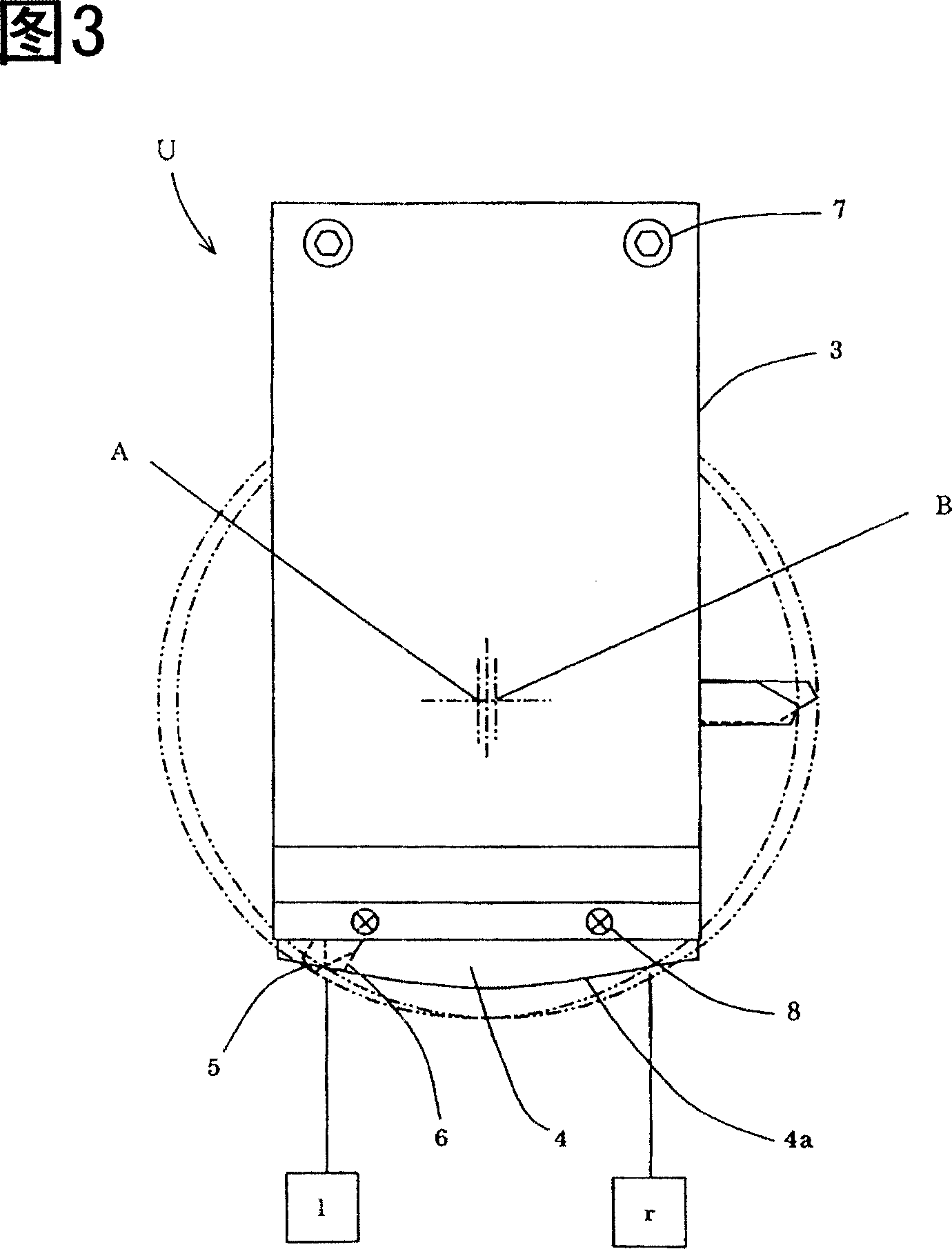

[0036] Fig. 1 is a front view of a first embodiment of the present invention. FIG. 2 is a side view of FIG. 1 . FIG. 3 shows a plan view of FIG. 1 .

[0037]接触辊1被图中未示出的公知装置可旋转地支撑在框架2上,在相对于纱条行走路径的接触辊1的上游,用于使纱条往复运动的横移装置U、U’交替的水平配置。

[0038] 另外,在本申请文件中,“对于各个线轴……具有接触辊”,不仅限于对应于每个线轴具有多个接触辊,而且还包括象本实施例那样,对于横移装置U、U’采用共用的接触辊1的情况。

[0039] 在横移装置U中,在壳体3中配置可以以中心A(图3)作为旋转中心逆时针旋转的中空旋转轴(图中未示出)三片上侧旋转叶片5分别具有120度相位差地固定在该中空旋转轴上。导纱器

[0040] (图中未示出)固定在各旋转叶片5的前端上,利用该导纱器向一个方向(图3中是从l侧到r侧)运送纱条。

[0041] 另一方面,以相对于上述中心A偏心的B为中心,可向与上述中空旋转轴相反的方向同时旋转的实心轴(图中未示出),配置在上述中空旋转轴的中空部内,三片下侧旋转叶片6分别具有120度相位差地固定在该实心轴上。在各旋转叶片6的前端固定导纱线(图中未示出),利用该导纱器向另一个方向(图3是从r侧到l侧)运送纱条。由于这些导纱器和其驱动系统的结构是公知的,所以省略对其的说明。

[0042] 另外,在本实施例中,虽然直接接触纱条的导纱器(图中未示出)分别固定在旋转叶片5、6的前端,但是也可以不安装导纱器,直接由旋转叶片运送纱 strip.

[0043] 旋转叶片5和6相互向相反方向旋转,其一个旋状叶片按照向反向旋转的另一个旋状叶片与导轨4上的纱条行程端l、r(图3)按照以几何学相遇...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com