Convenient-to-move diameter-variable flat-mouth suction pipe cover equipment for efficient dust collection

A straw cover and flat nozzle technology, which is applied in the field of variable-diameter flat nozzle straw cover equipment, can solve problems such as inconvenient maintenance, affecting suction, energy consumption, and pipe wall wear, so as to reduce labor costs and safety hazards, and prolong service life , Increase the effect of friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

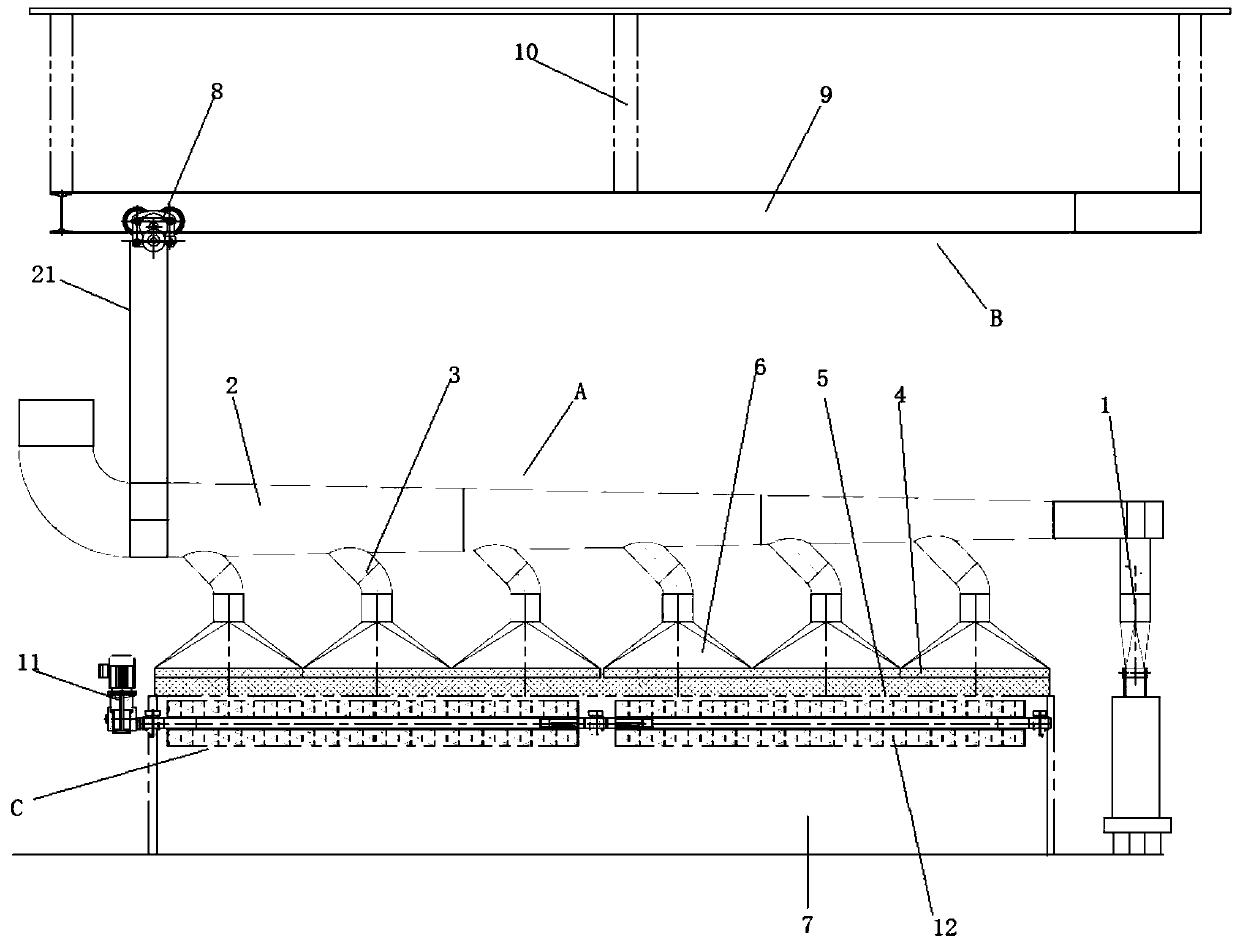

[0037] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, thereby making a clearer definition of the protection scope of the present invention;

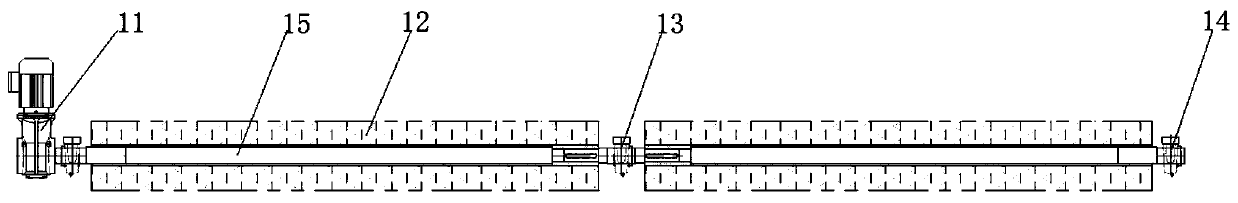

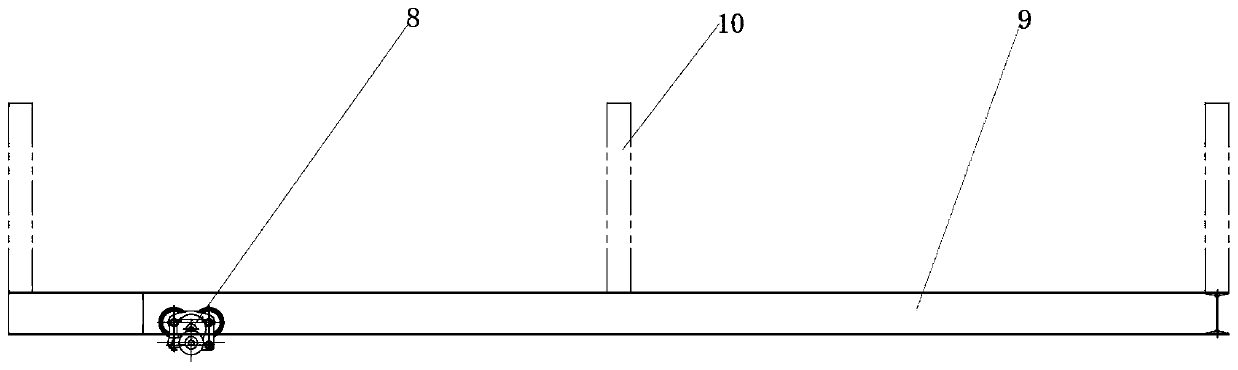

[0038] like Figure 1-6 As shown, the technical solution of the present invention is a highly efficient dust-absorbing and easy-to-move variable-diameter flat-mouth suction pipe cover equipment including a variable-diameter flat-mouth suction pipe cover A, a suction cover hanging walking track B, an electric roller brush C and a kiln car 7;

[0039] Reduced-diameter flat-mouth straw cover A includes a mobile swivel 1, a reduced-diameter suction pipe 2, a suction hood bend 3, a suction hood flat suction nozzle 4 and a suction hood 6, and the right end of the variable-diameter suction pipe 2 is rotated and installed on the mobile swivel 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com