Swelling machine and manufacturing method of swelling machine floating body

A wave machine and floating body technology, applied in the field of aquaculture equipment, can solve the problems of insufficient diffusion capacity of water bodies and insufficient diffusion capacity of impeller-type aerators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-27 :

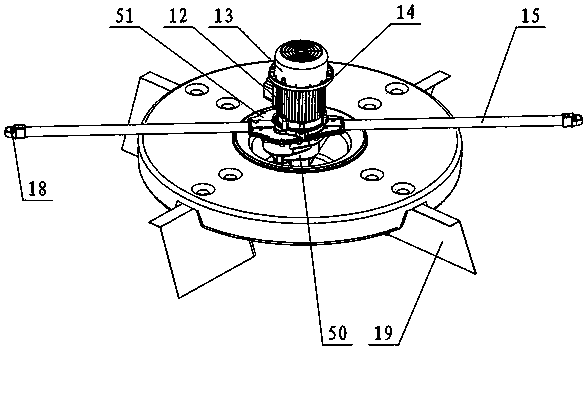

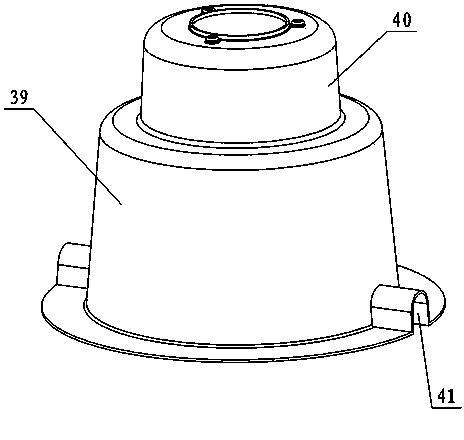

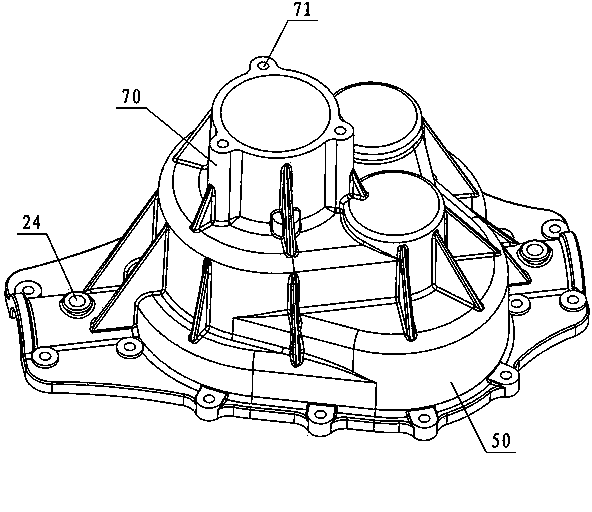

[0055] A surge machine mainly includes: a motor 12, a reduction box 20, a floating body 1, blades 19, and a fixed rod 15. The motor 12 is a vertical motor, and the motor 12 is vertically installed on the reduction box 20. The floating body 1 can be A hollow shell, the floating body 1 has an installation position 10 for installing blades on the periphery of the lower part, and the blades 19 are installed in the installation position 10; the middle part of the floating body 1 has a connection position 4 matching the flange, and the upper and lower shells of the connection position 4 are integrated . The upper and lower shells can be processed and formed separately and fixed into a whole. The two layers in the middle are combined as the connection position 4 of the flange. The output shaft 36 of the reduction box 20 drives the floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com