Pneumatic conveying installation

A technology of pneumatic conveying and conveying equipment, which can be used in applications, tobacco, cigarette manufacturing, etc., and can solve the problem of high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

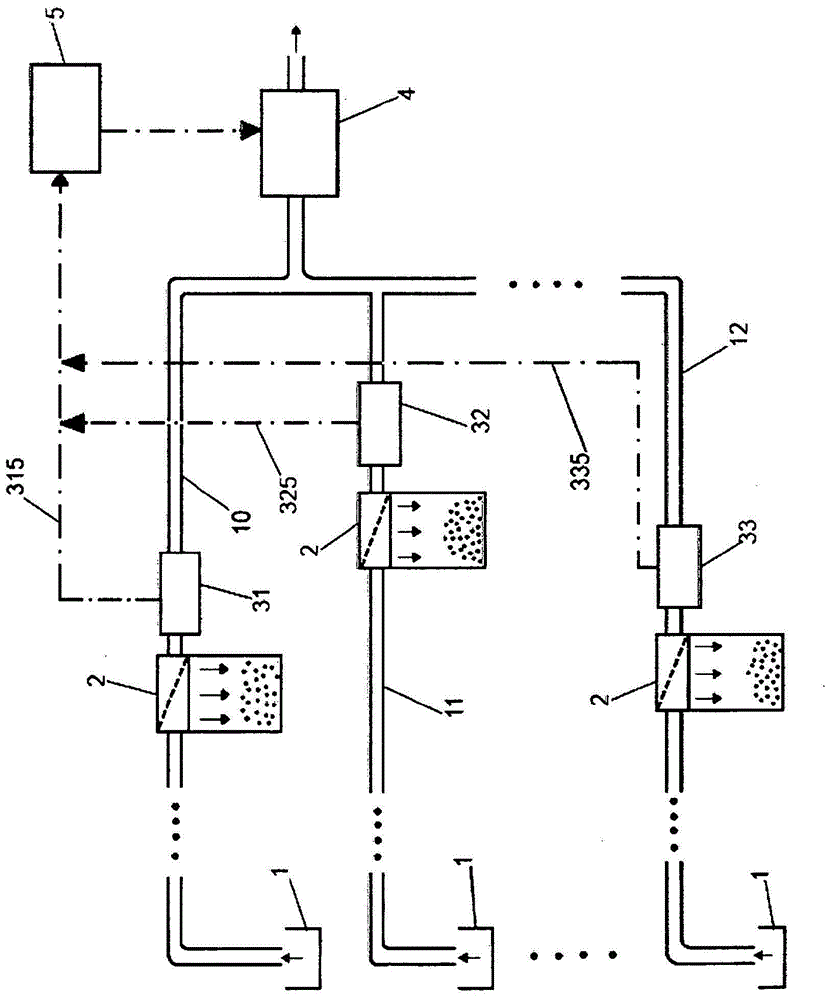

[0015] The drawing shows in a block diagram the essential components of a pneumatic conveying device according to the invention, in particular a shredded tobacco conveying device.

[0016] A plurality of conveying lines 10 , 11 , 12 are provided, which are each supplied with conveying material in the supply region 1 . Integrated in the conveying lines 10 , 11 , 12 are separating devices 2 which separate the conveying material, in particular shredded tobacco, from the conveying air. In order to generate a pressure drop, a common compressor (collectively referred to as a conveying device) 4 is arranged downstream of the conveying lines 10 , 11 , 12 . The device shown is designed as a suction conveyor device, but a pressure conveyor arranged upstream of the separating device 2 can also be operated according to the invention.

[0017] Downstream of the separating devices 2 , a regulating unit 31 , 32 , 33 is arranged in each case, which regulates a throttle device (not shown in d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com