A novel ultra-high pressure pressure sensor and pressure detection method

A pressure sensor, ultra-high pressure technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through mechanical components, instruments, etc., can solve the problems that affect the pressure measurement accuracy, temperature drift and measurement error, so as to improve the versatility and reduce the influence of temperature , the effect of meeting the pressure measurement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

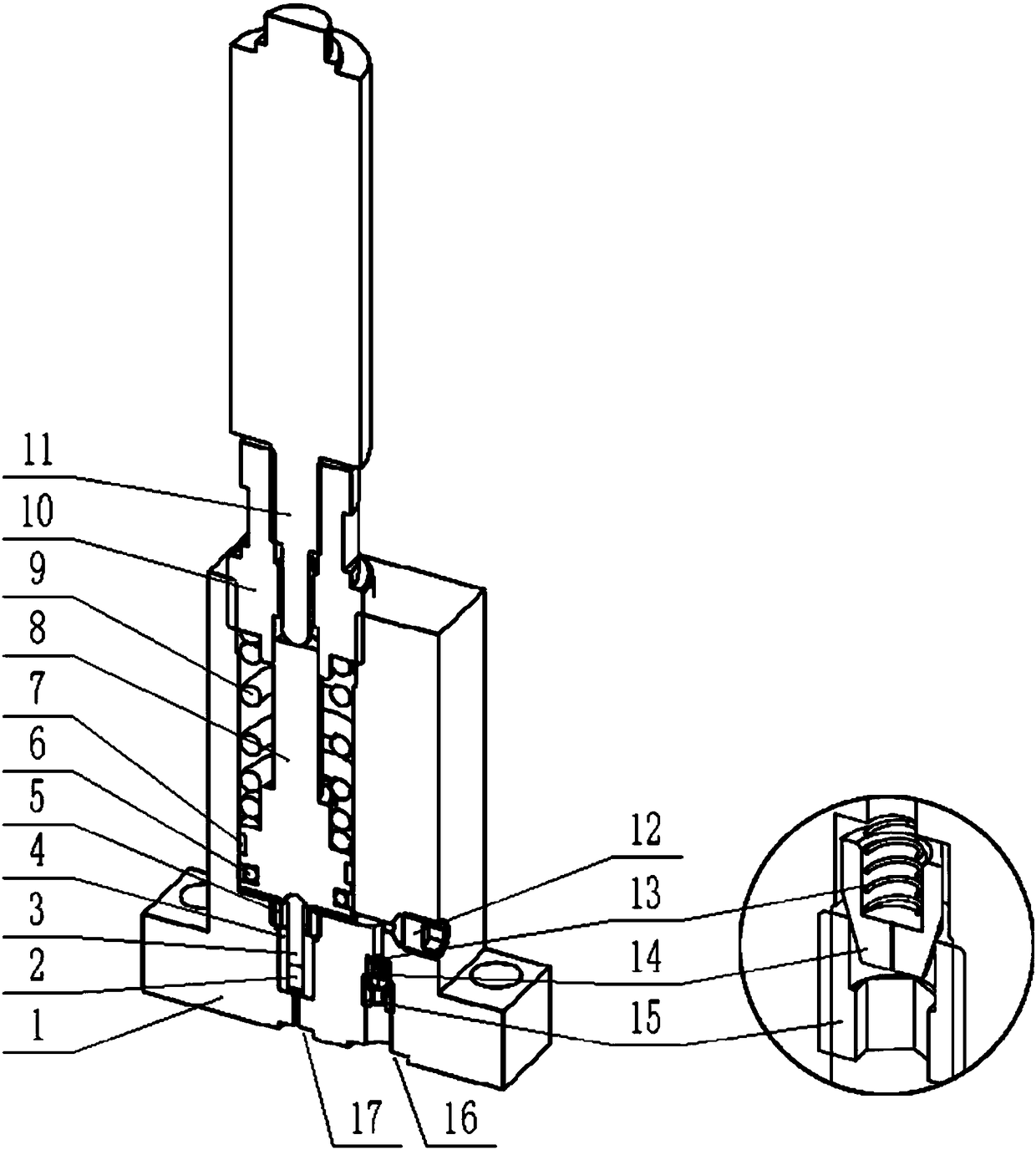

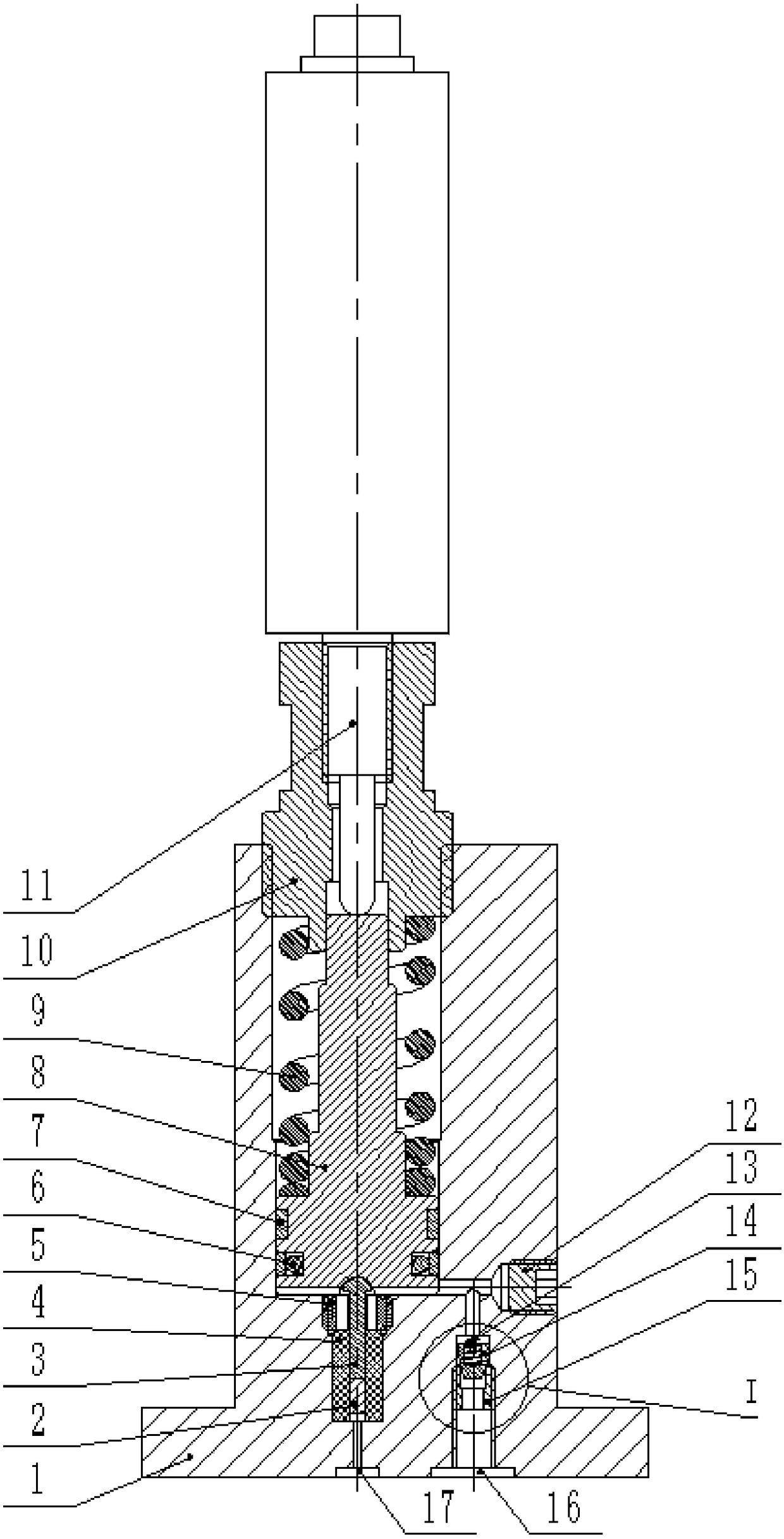

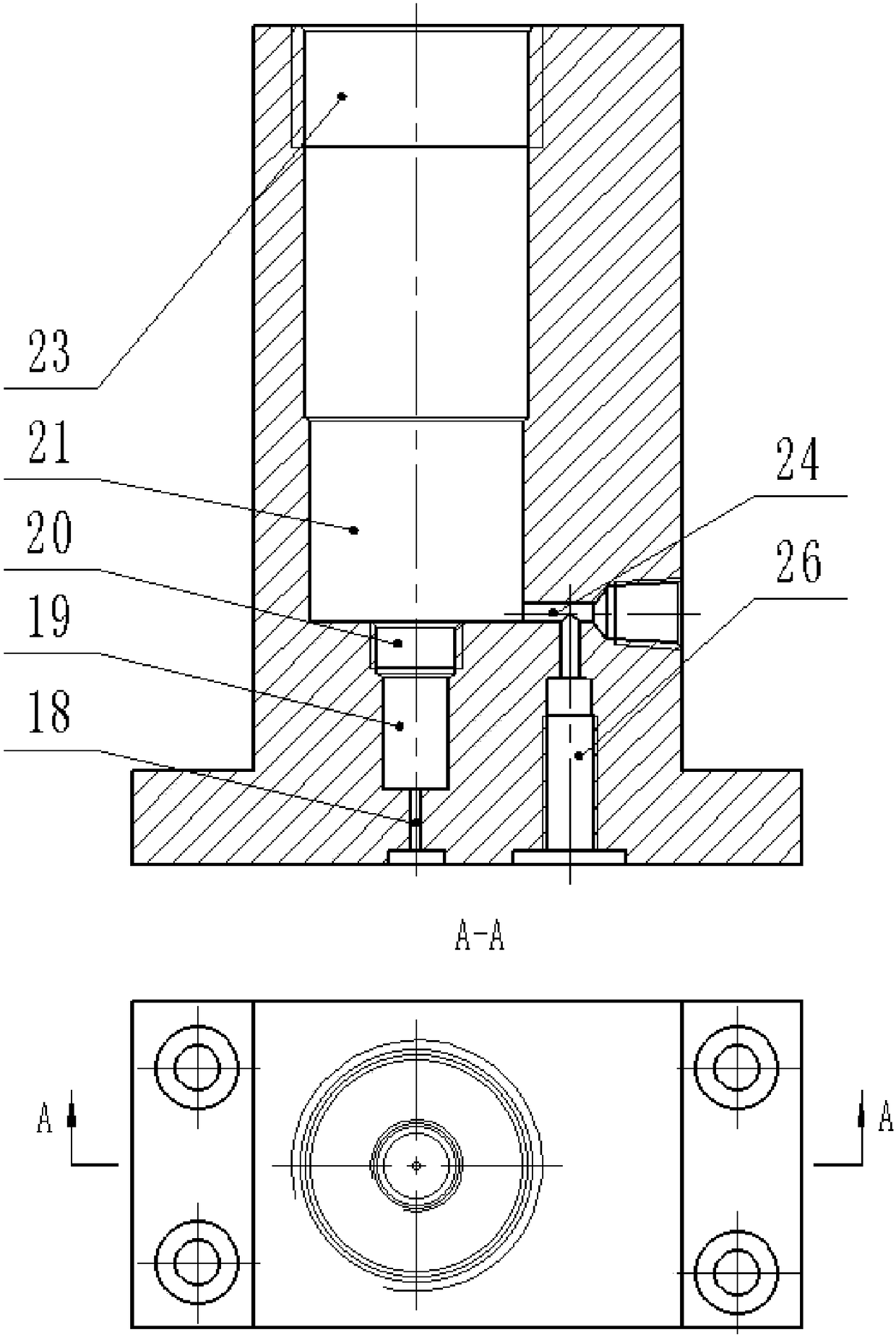

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] Such as Figure 1~2 As shown, a new type of ultra-high pressure pressure sensor, its structure is composed of main body 1, ceramic core 2, steel rod core 3, ceramic sleeve 4, outer nut 5, gland ring 6, guide ring 7, spring rod 8, preload A spring 9, a cap 10, a displacement sensor 11, a screw plug 12, a damping unit, an oil return port 16 and an oil inlet 17 are formed. Among them, an annular flow channel is formed between the ceramic core 2, the steel rod core 3 and the ceramic sleeve 4; the preload spring can be a cylindrical spring or a disc spring, and a cylindrical spring is used when the pressure is 70MPa-200MPa, and a cylindrical spring is used when the pressure exceeds 200MPa. Disc spring, the hydraulic system pressure in the present embodiment does not exceed 200MPa, and its preload spring selects cylindrical spring for use.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com