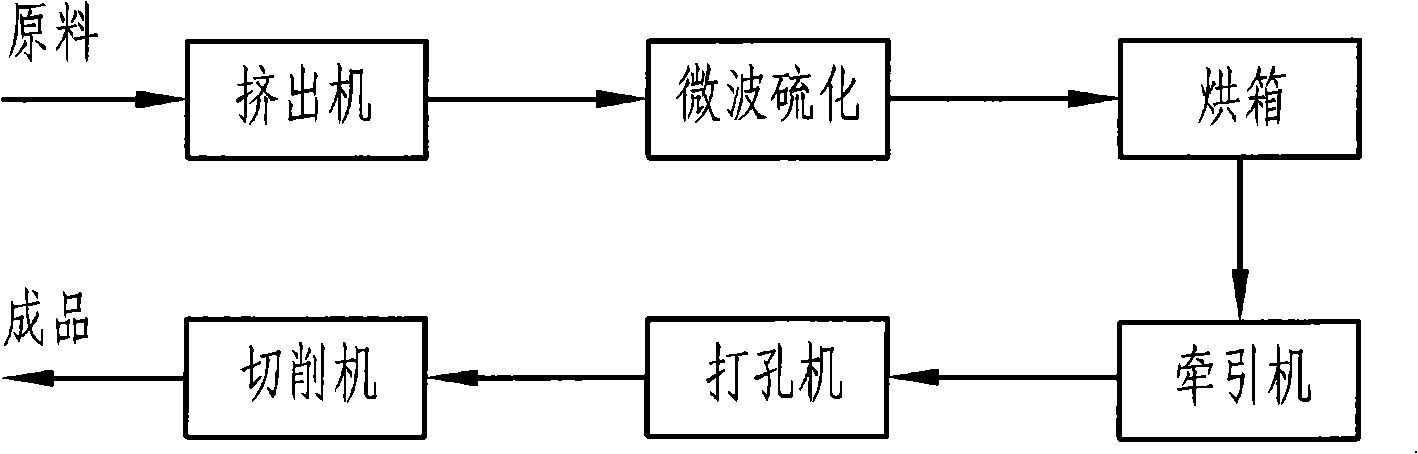

On-site bus control apparatus and method of rubber seal strip extrusion production line

A technology of field bus control and rubber sealing strip, which is applied in the field of control devices and field bus control devices, can solve the problems of large delay, long time, and low efficiency, and achieve the effects of improving production efficiency, avoiding waste products, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

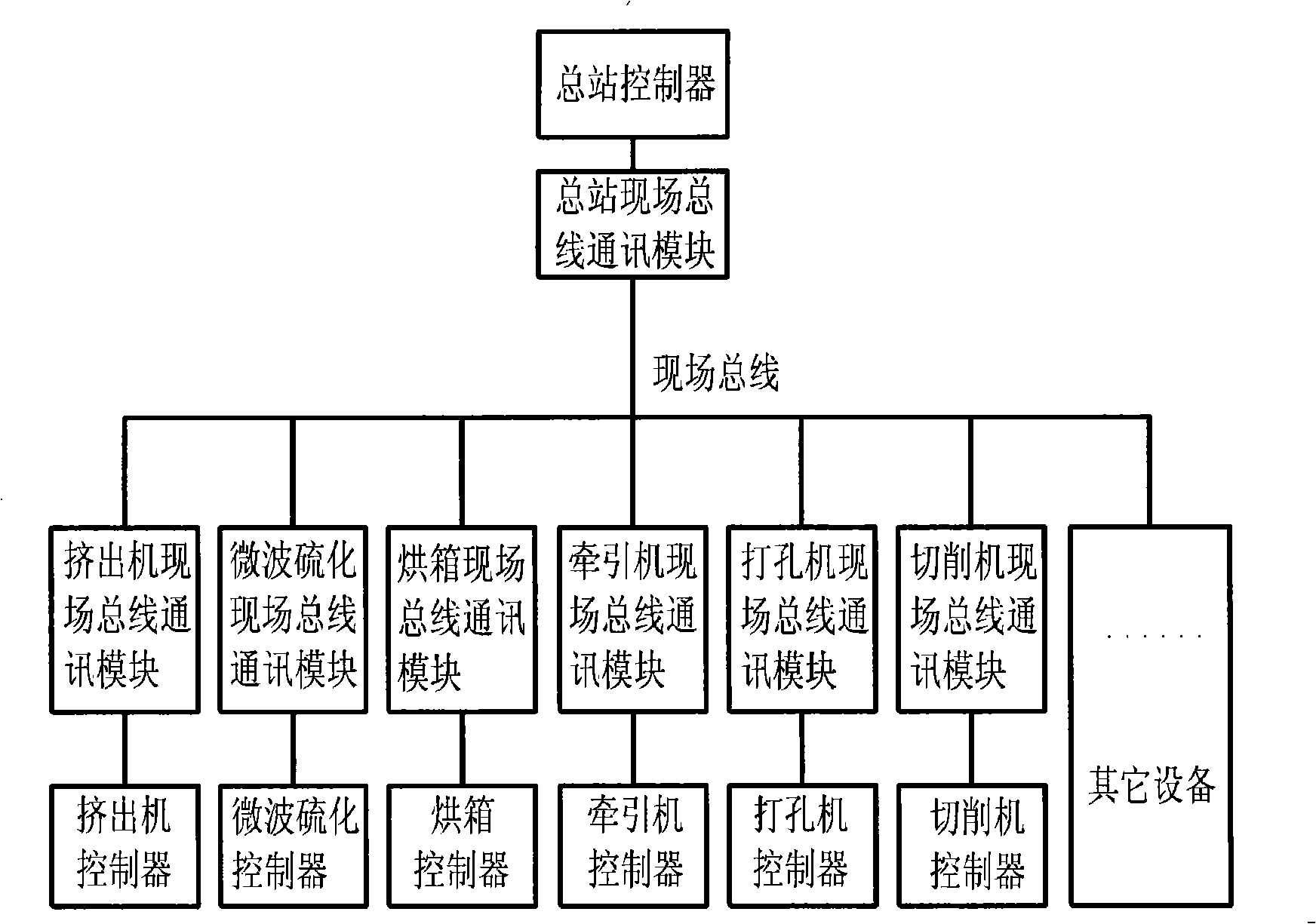

Embodiment

[0028] In the implementation of the specific production line in this embodiment, the total station controller selects the PLC of Mitsubishi Corporation Q02 series (comprising some modules required for the normal operation of the PLC, such as substrates, power supply modules, etc.), and the total station field bus communication module selects Mitsubishi Corporation's QJ61BT11N, The field bus selects Mitsubishi's CC-Link bus. Extruder, microwave vulcanization equipment, oven, haul-off machine, punching machine, cutting machine and other equipment controllers use Mitsubishi FX2N series PLC, corresponding extruder, microwave vulcanization equipment, oven, haul-off machine, punching machine Machines, cutting machines and other stand-alone equipment, their fieldbus communication modules use Mitsubishi's FX 2N -32CCL. Connect each PLC and field bus communication module (QJ61BT11N, FX 2N -32CCL) according to figure 1 The logical structure shown is connected according to the CC-Link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com