Material mixing and fermenting device

A fermentation device and material mixing technology, applied in the fields of fine chemical industry, pharmacy, and bioengineering, can solve the problems of high cost, affect the fermentation quality, and inconvenient maintenance, and achieve the effect of low cost and simple heating structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

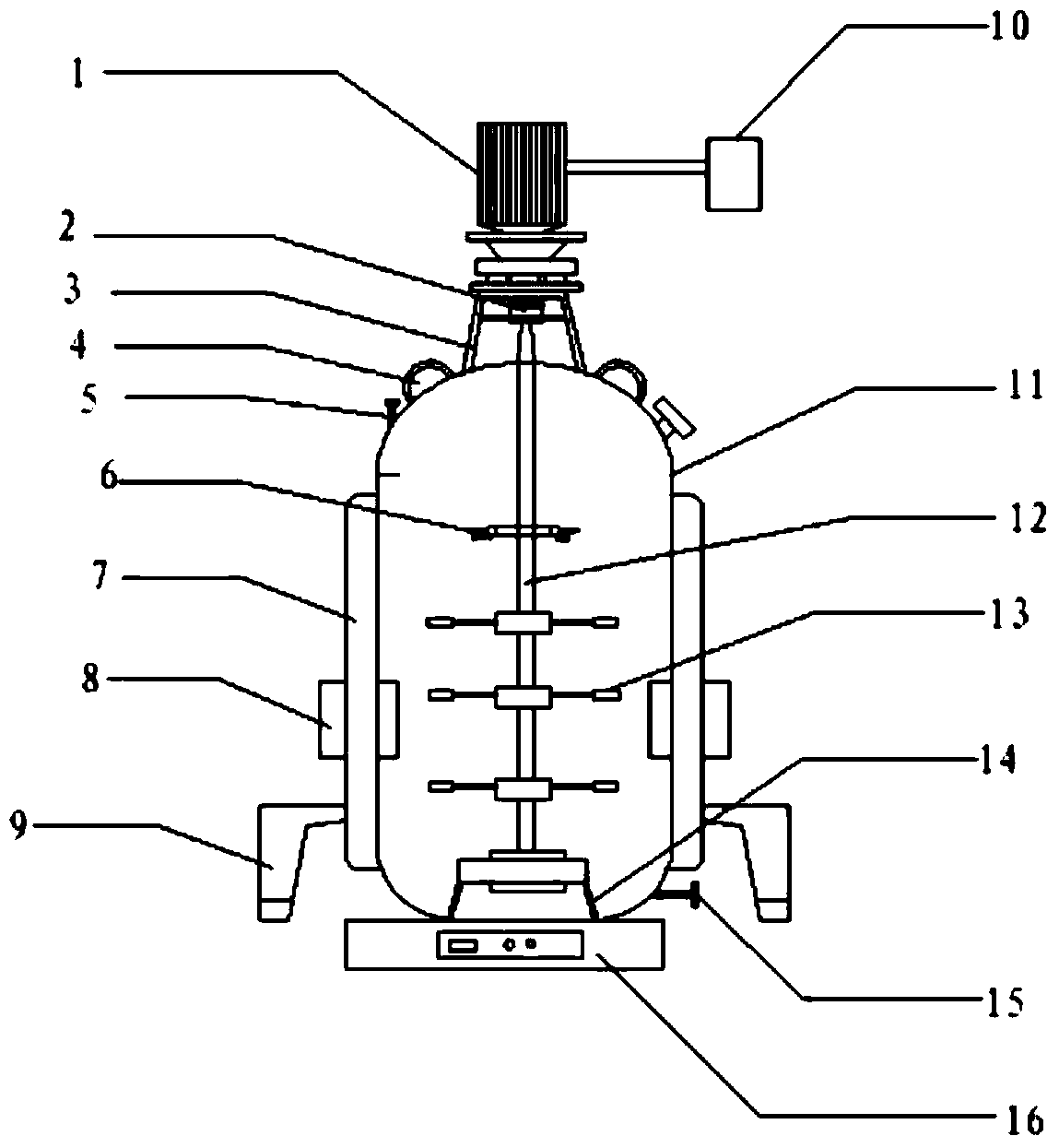

[0018] The present invention will be further described below in conjunction with accompanying drawing. Such as figure 1 As shown, a material mixing fermentation device includes a tank body 11, a temperature measuring device 8, a rotating shaft 12, a blade 13, a defoamer 6, a tank body support 9, an electric hob 16, a motor 1, a coupling 2, and a frequency converter 10 , Motor bracket 3. The top of the tank is provided with a feed inlet, lifting lugs and manholes, and the lifting lugs are symmetrically arranged on both sides of the tank. The bottom of the tank is a flat structure so that the tank can be directly placed on the electric stove for heating. There is an insulation layer around the tank, which can strengthen the insulation effect of the material in the tank; the temperature measuring device is located on the side wall of the tank, and the temperature measuring device can directly observe the temperature value in the tank from outside the tank; the rotating shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com