Ultrasonic liquid level measurement method and device

A liquid level measurement device and liquid level measurement technology are applied in the direction of measuring devices, liquid/fluid solid measurement, and lubrication indicating devices, etc., which can solve problems such as large fluctuations in liquid levels, mist entrainment, and difficulties in accurate liquid level measurement. Achieve the effect of simple and convenient operation and stable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

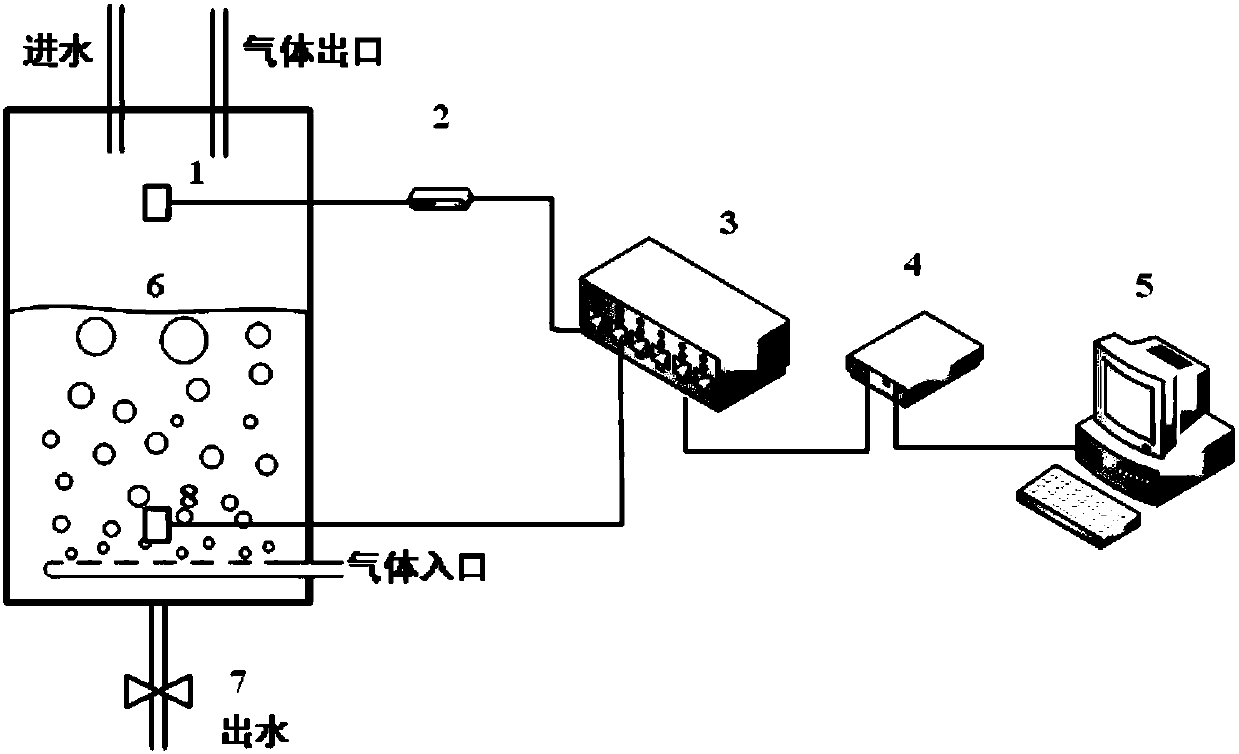

[0033] Embodiment 1: Static liquid level measurement of gas-liquid bubbling device

[0034] The liquid used in the experiment is water, which can be injected from the upper water injection port or flow out from the lower valve, thereby changing the liquid level in the gas-liquid bubbling device 6 . The acoustic signal measured by the receiving probe 1 is converted into an electrical signal and then recorded by the acquisition card 4 and the computer 5 . The transmitting probe 8 generates a 200kHz square wave sound signal, and the receiving probe 1 has a sampling frequency of 500kHz.

[0035] The specific experimental plan is as follows:

[0036] (1) During the experiment, the transmitting probe 8 is located below the gas-liquid bubbling device 6, 50 mm away from the gas inlet, and the receiving probe 1 is placed above the gas-liquid bubbling device 6, and the distance from the transmitting probe 8 is 400 mm

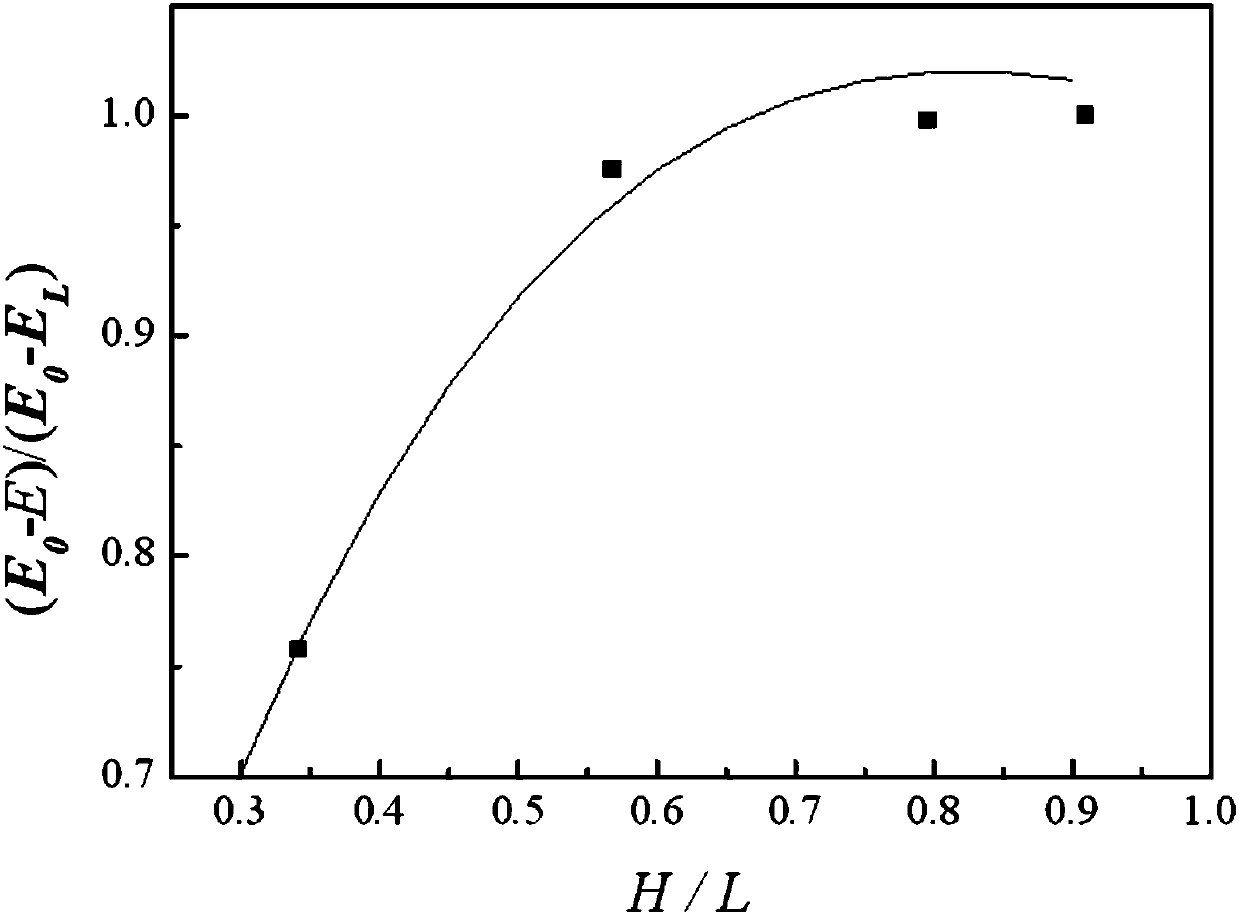

[0037] (2) The liquid level starts from the bottom of the gas-liqu...

Embodiment 2

[0042] Example 2: Dynamic liquid level measurement of gas-liquid bubbling device

[0043] The liquid used in the experiment is water, which can be injected from the upper water injection port or flow out from the lower valve, thereby changing the liquid level in the gas-liquid bubbling device 6 . The acoustic signal measured by the receiving probe 1 is converted into an electrical signal and then recorded by the acquisition card 4 and the computer 5 . The transmitting probe 8 generates a 175kHz square wave signal, and the receiving probe 1 has a sampling frequency of 500kHz.

[0044] (1) Close the water outlet valve 7 in the experiment, inject liquid from the liquid injection port on the top of the gas-liquid bubbling device 6, the liquid level height increases by 50mm per minute, and feed a flow of 20 cubic meters per hour into the gas-liquid bubbling device The air, the liquid level increases continuously from 0 to the receiving probe 1, and the receiving probe 1 continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com