Aeration method, its apparatus and its system

An aeration device and aeration method technology, applied in water aeration, chemical instruments and methods, degassed water/sewage treatment, etc., can solve the problems of energy consumption, poor gas dissolution efficiency, and low efficiency, and achieve the promotion of convection , Prolong the aeration time, improve the effect of dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

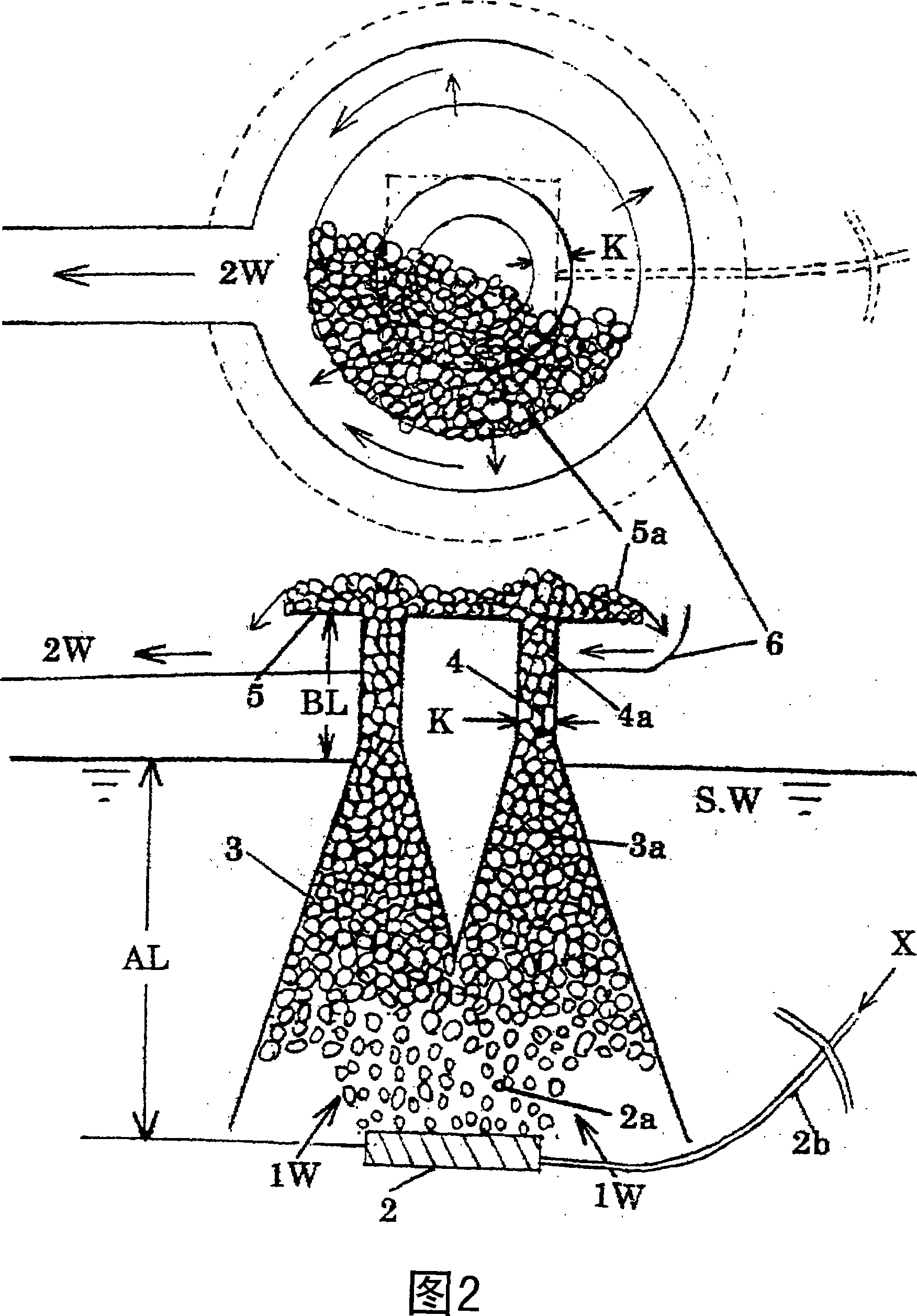

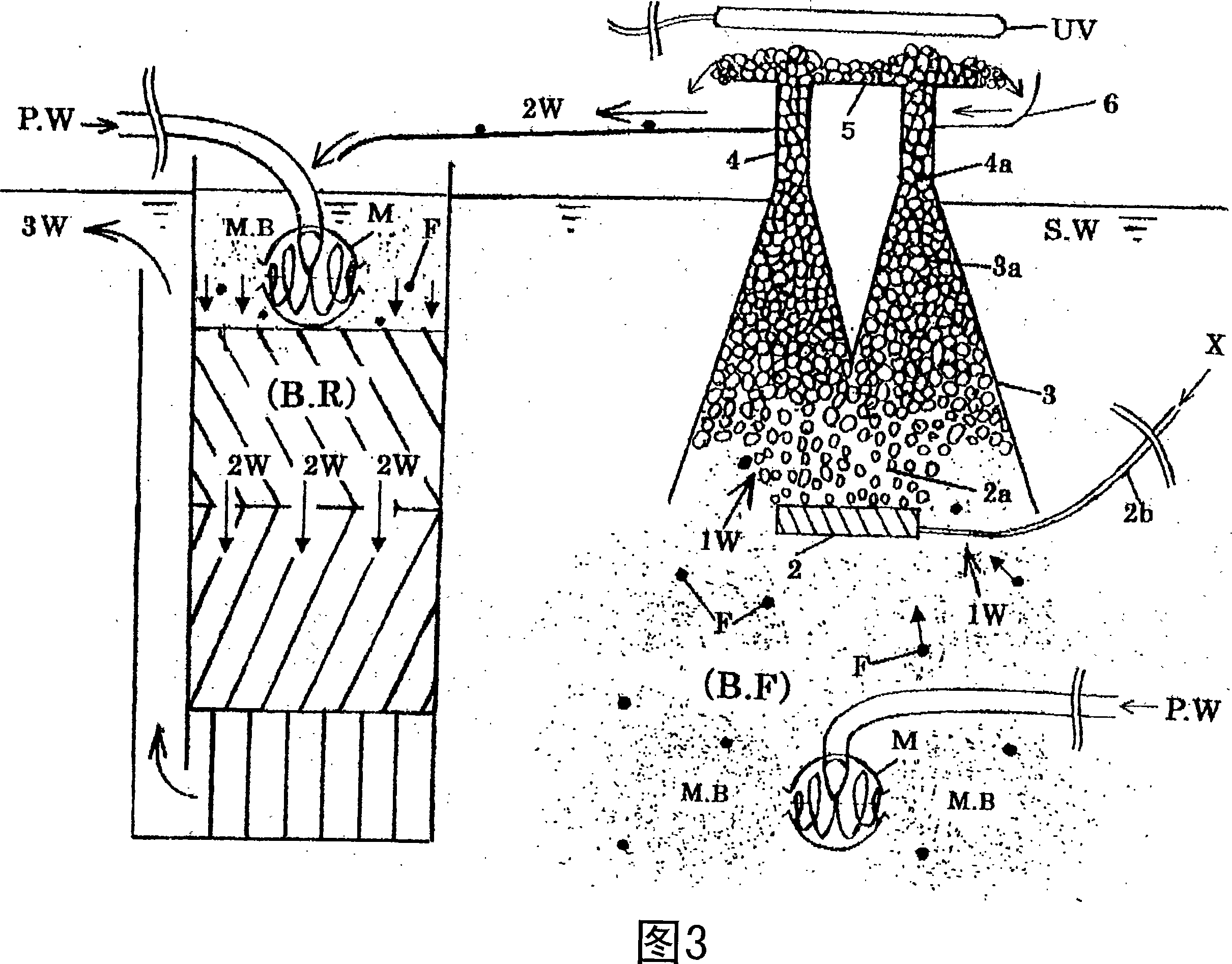

[0186] Hereinafter, embodiments of the aeration method, aeration device, and aeration system of the present invention will be described based on FIGS. 1 to 15 .

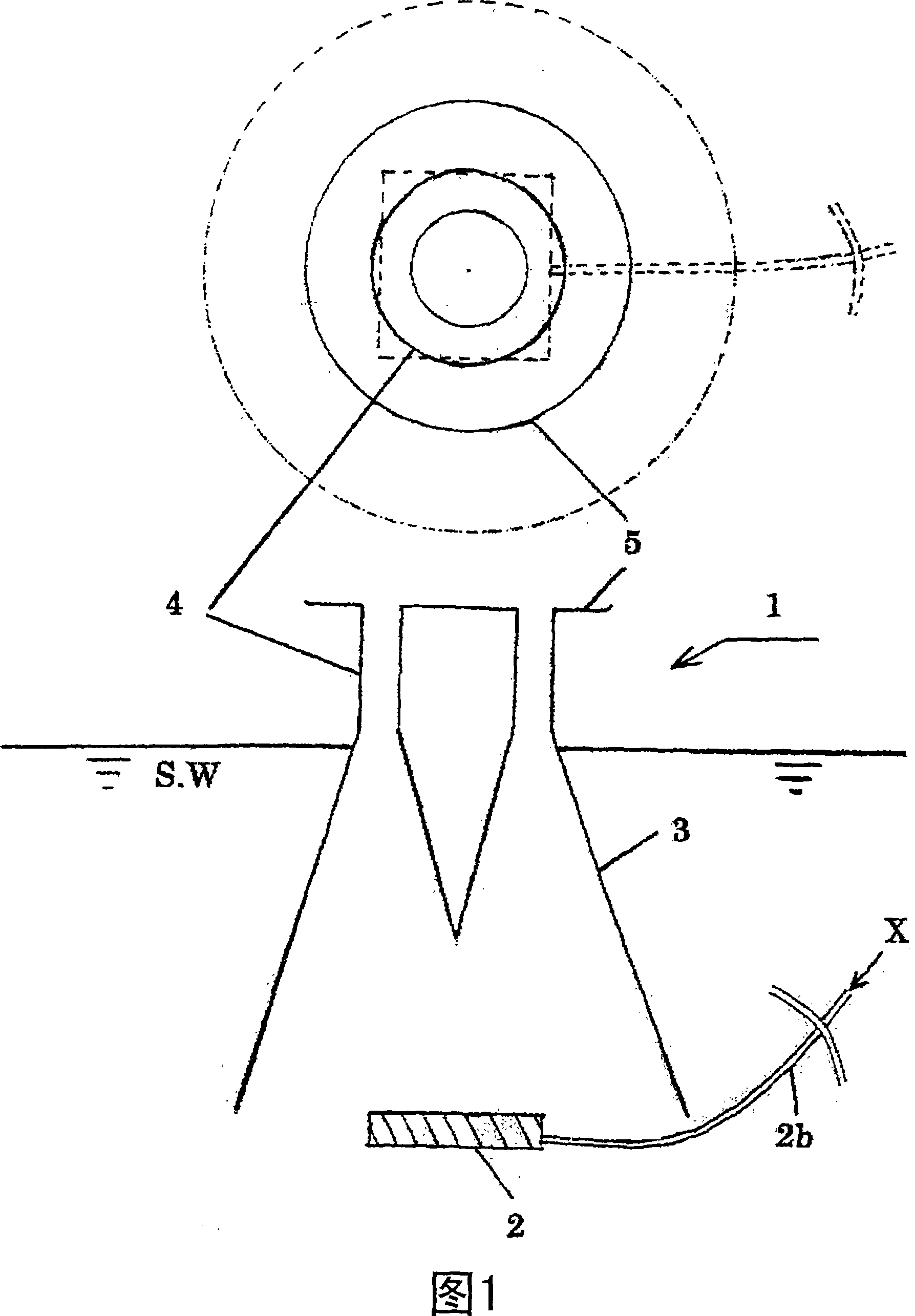

[0187] Fig. 1 is a conceptual diagram of an aerator according to a first embodiment, the upper side is a perspective view, and the lower side is a front view.

[0188] In Fig. 1, 1 is the aeration device according to the first embodiment, 2 is the air bubble generating part, 2b is a gas supply pipe for supplying gas to the air bubble generating part 2, and 3 is used to release the air bubbles generated from the air bubble generating part 2. The bubble concentration part that gathers together, 4 is the bubble ascending channel that can make the bubbles after the concentration rise to the position above the water surface S.W, 5 is the liquid bubble exposure that is used for prolonging the aeration time of the liquid bubbles produced in the bubble ascending channel 4 as much as possible in the atmosphere. Gas section, X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com