A polycarbonate additive mixing and adding system and using method thereof

A technology of polycarbonate and additives, which is applied in the field of polycarbonate additive mixing and adding systems, can solve the problems of polycarbonate product quality impact, etc., and achieve the effects of excellent solubilization effect, simple structure, and improved mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

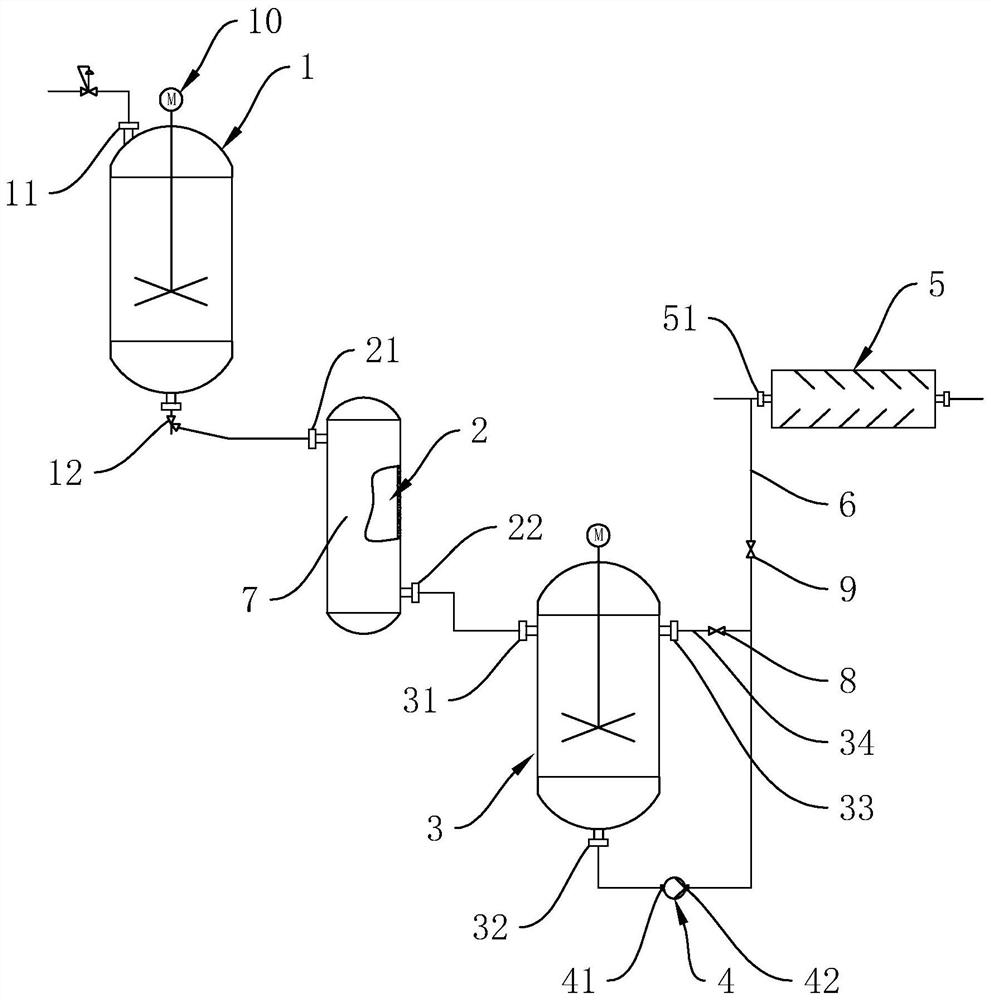

[0043] refer to figure 1 , is a polycarbonate additive mixing and adding system disclosed in the present invention, comprising a mixing preparation tank 1 , a filter 2 , a feeding tank 3 , a pumping pump 4 and a static mixer 5 connected in sequence through a delivery pipe 6 .

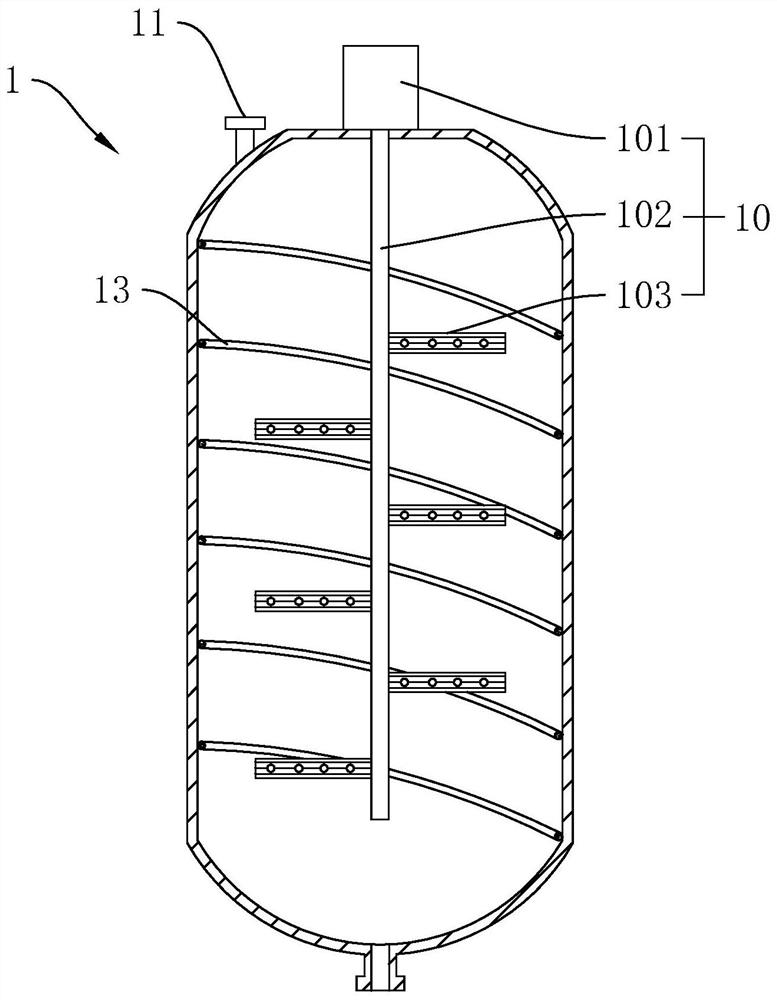

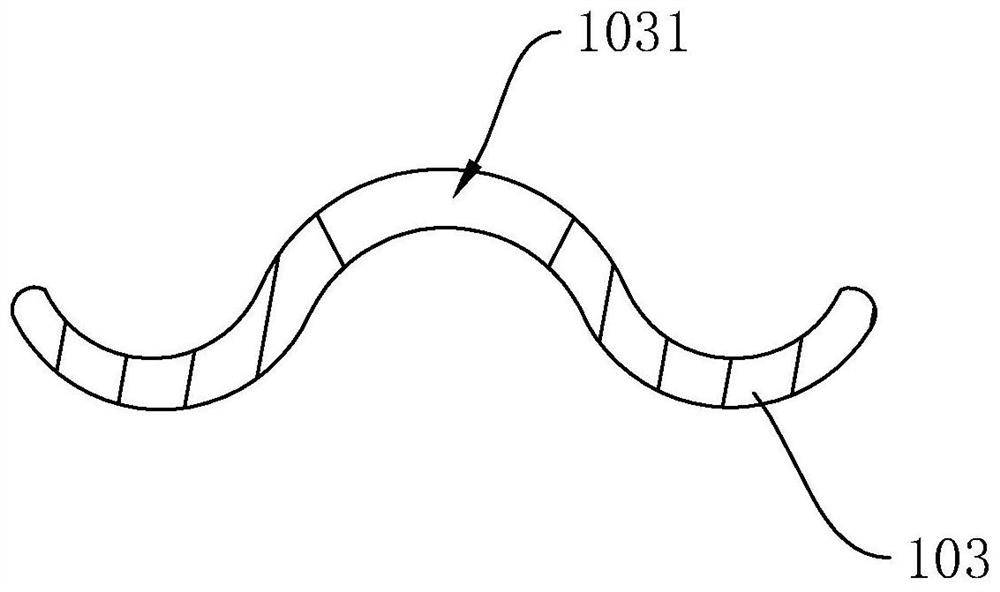

[0044] combine figure 2 , the terminator of polycarbonate is housed in the mixed preparation tank 1, the top of the mixed preparation tank 1 is provided with a feed hopper 11, and a tank bottom valve 12 is installed at the bottom of the mixed preparation tank 1, and both the terminator and the auxiliary agent are fed from the feeder. The hopper 11 is dropped into the mixing preparation tank 1. A heat conduction pipe 13 is fixedly installed on the inner wall of the mixing preparation tank 1, and the heat conduction pipe 13 is spirally wound along the central axis of the mixing prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com