Aluminum dihydrogen tripolyphosphate continuous production method and device

A technology of aluminum dihydrogen tripolyphosphate and aluminum dihydrogen phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as large fluctuations in purity, low degree of automation, and unstable product quality, and achieve Low production cost, good economic and social benefits, and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

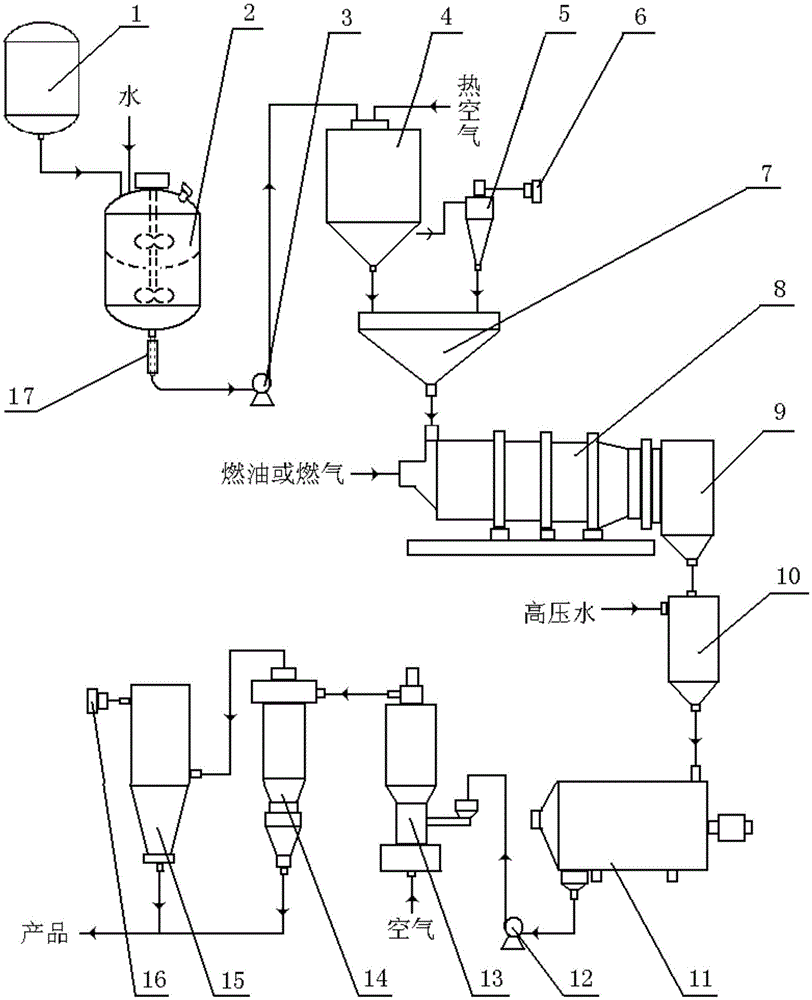

[0039] A method for continuously producing aluminum dihydrogen tripolyphosphate, comprising the following steps:

[0040] (1) Neutralization reaction: under normal temperature and pressure, add quantitative continuous water and 85% industrial phosphoric acid to the double-chamber reaction kettle 2 at a weight ratio of 0.25:1, stir, and mix with 85% industrial phosphoric acid and activated alumina’s P / Al molar ratio=2.9:1 ratio, the activated alumina is quantitatively and continuously passed into the double-chamber reactor 2 in the form of screw feeding, and the liquid aluminum dihydrogen phosphate is obtained after the neutralization reaction;

[0041] (2) Spray drying: the specific gravity is 1.35, and the liquid aluminum dihydrogen phosphate heated to a temperature of 50°C through the pipeline heater 17 is continuously and uniformly passed into the centrifugal spray dryer 4 through the liquid pump 3, and the nozzle speed of the centrifugal spray dryer 4 is The control is 13...

Embodiment 2

[0049] A method for continuously producing aluminum dihydrogen tripolyphosphate, comprising the following steps:

[0050] (1) Neutralization reaction: under normal temperature and pressure, add quantitative continuous water and 85% industrial phosphoric acid to the double-chamber reactor 2 at a weight ratio of 0.30:1, stir, and mix with 85% industrial phosphoric acid and the P of activated alumina. / Al molar ratio=3.0:1 ratio, the activated alumina is quantitatively and continuously passed into the double-chamber reactor 2 in the form of screw feeding, and the liquid aluminum dihydrogen phosphate is obtained after the neutralization reaction;

[0051] (2) Spray drying: the specific gravity is 1.38, and the liquid aluminum dihydrogen phosphate heated to a temperature of 55°C through the pipeline heater 17 is continuously and evenly passed into the centrifugal spray dryer 4 through the liquid pump 3, and the nozzle speed of the centrifugal spray dryer 4 is The control is 14500r / ...

Embodiment 3

[0059] A method for continuously producing aluminum dihydrogen tripolyphosphate, comprising the following steps:

[0060] (1) Neutralization reaction: under normal temperature and pressure, add quantitative continuous water and 85% industrial phosphoric acid to the double-chamber reaction kettle 2 at a weight ratio of 0.32:1, stir, and add 85% industrial phosphoric acid to the P of activated alumina. / Al molar ratio=3.0:1 ratio, the activated alumina is quantitatively and continuously passed into the double-chamber reactor 2 in the form of screw feeding, and the liquid aluminum dihydrogen phosphate is obtained after the neutralization reaction;

[0061] (2) Spray drying: the specific gravity is 1.40, and the liquid aluminum dihydrogen phosphate heated to a temperature of 60°C through the pipeline heater 17 is continuously and evenly passed into the centrifugal spray dryer 4 through the liquid pump 3, and the nozzle speed of the centrifugal spray dryer 4 is The control is 14500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com