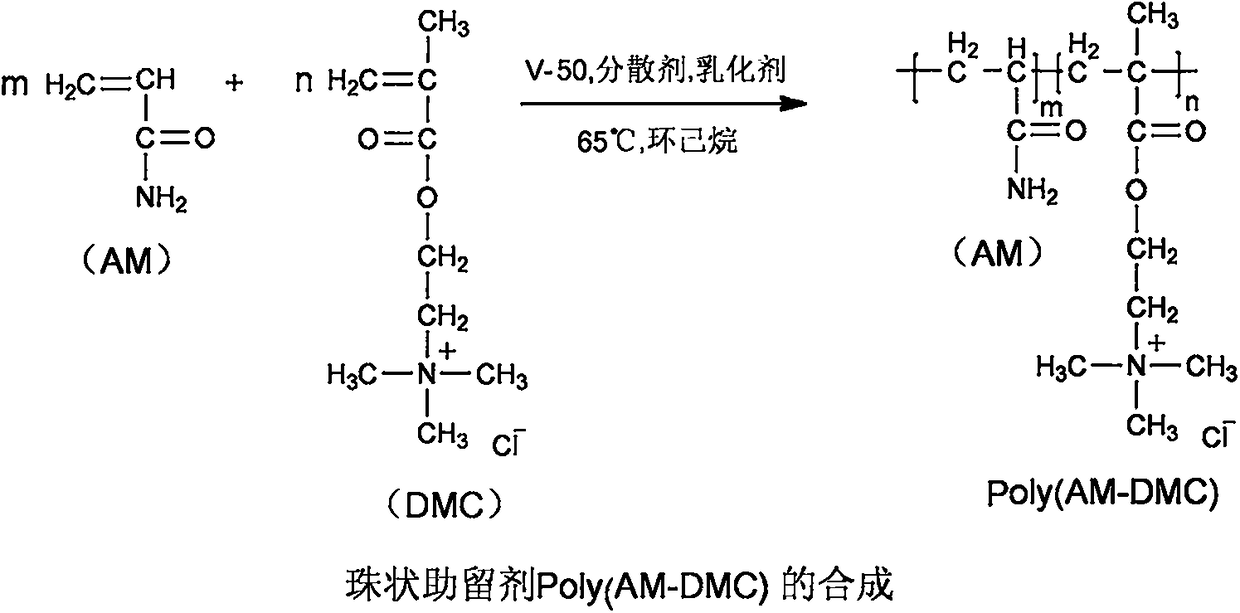

Preparation method and paper pulp retention aiding application of bead-like cationic polyacrylamide retention aid

A technology of polyacrylamide and cation, which is applied in the direction of retention aid addition, paper, papermaking, etc., can solve the problems of unfavorable papermaking process efficiency, improvement, long dissolution time, etc., achieve good pulp drainage performance, improve coordination effect, and good The effect of dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, preparation of beaded cationic polyacrylamide retention aid

[0034] Water phase preparation: Weigh 14.5g of acrylamide (AM), 4.5g of cationic monomer acryloyloxyethyltrimethylammonium chloride (DAC) and dissolve them in 50ml of deionized water at 40-45°C to form a transparent single aqueous solution, then add 0.015g initiator V-50 and ammonium persulfate (weight ratio is 1: 1), mix well, and prepare the aqueous phase;

[0035] Oil phase preparation: Weigh 0.80g emulsifier Span-60, 0.80g emulsifier span-80, 0.20g initiator V60 azobisisobutyronitrile and put them into a 500mL four-phase tank equipped with a mechanical stirrer, a condenser tube and a nitrogen conduit. Add 200mL cyclohexane to a round-bottomed flask, pass through condensed water, start stirring, and raise the temperature to 45°C until the emulsifier and initiator are completely dissolved to form a transparent oil phase;

[0036] Polymerization reaction: The two systems (water phase and oil p...

Embodiment 2

[0038] Embodiment 2, the preparation of beaded polyacrylamide retention aid

[0039] Except that the consumption of the initiator of the aqueous phase preparation step is changed into V-50 and ammonium persulfate meter 0.03g (weight ratio is 1: 1), other conditions are identical with embodiment 1, obtain diameter 1.0 ± 0.2mm bead-shaped retention aid Poly(AM-DAC), the solid content is 90%.

Embodiment 3

[0040] Embodiment 3, the preparation of beaded polyacrylamide retention aid

[0041] Except that the initiator of the aqueous phase preparation step is changed into VA044 and ammonium persulfate meter 0.03g (weight ratio is 1: 1), other conditions are the same as Example 1, obtain diameter 1.1 ± 0.2mm pearl shape retention aid Poly(AM- DAC) with a solid content of 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com