Auxiliary agent adding device and auxiliary agent adding process for polycarbonate

A polycarbonate and adding device technology, applied in the field of polycarbonate processing, can solve the problems of affecting product quality, easy to agglomerate, difficult to disperse evenly, etc., to achieve good quality and performance, increase flow efficiency, and dissolve efficiency. best results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

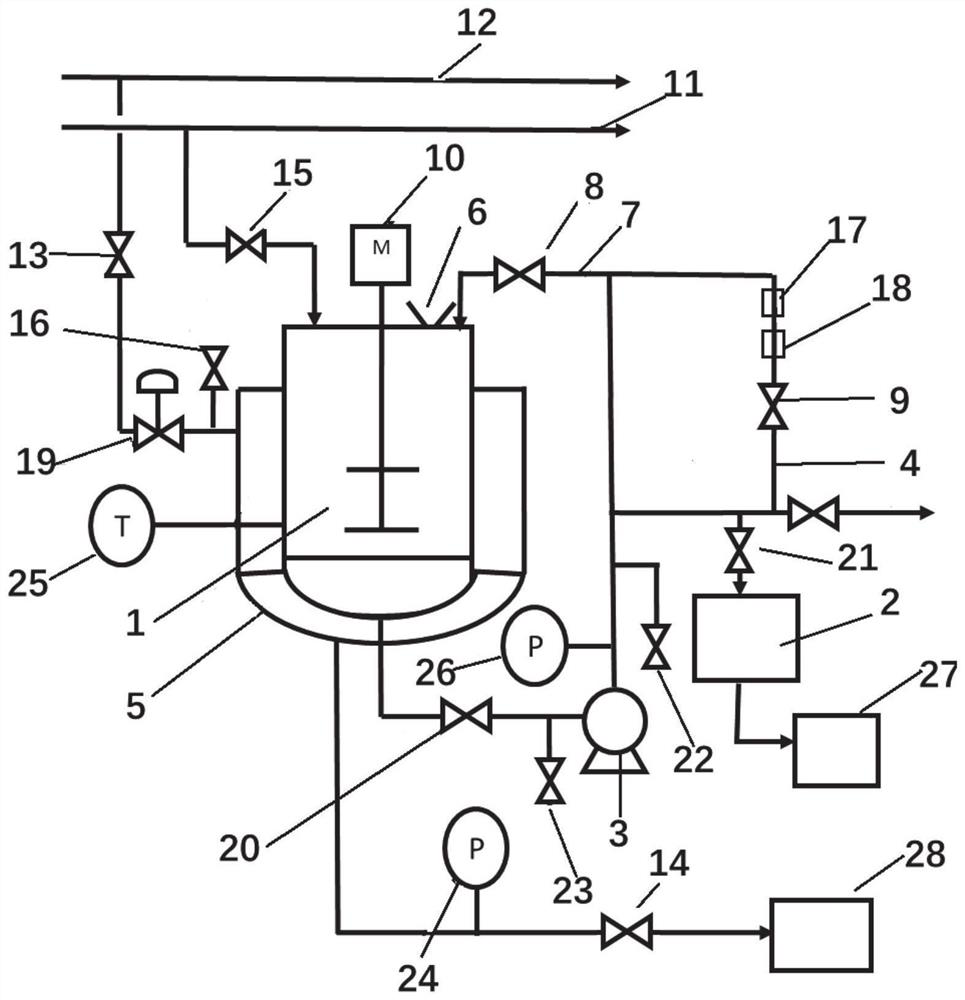

[0031] As mentioned in the background technology, in the process of producing polycarbonate, accelerating the melting of additives while ensuring the quality of polycarbonate products is a technical problem that needs to be solved urgently. To solve this technical problem, the present invention provides a The additive adding device and adding process of polycarbonate.

[0032] In one embodiment of the present invention, a polycarbonate additive adding device is provided, including a mixing preparation tank, a liquid storage tank, a pumping pump, and a delivery pipe, wherein the delivery pipe connects the mixing preparation tank, the liquid storage tank and the pumping The feed pumps are connected sequentially; the outside of the mixing preparation tank is provided with a steam heating jacket, and the top of the mixing preparation tank is provided with a feed hopper, and the pump is connected to the discharge port of the mixing preparation tank;

[0033] A circulation pipe is c...

Embodiment 1

[0056] A polycarbonate additive adding device, including a mixing preparation tank, a liquid storage tank, a material pump, and a delivery pipe connected in sequence through a delivery pipe, wherein the delivery pipe connects the mixing preparation tank, the liquid storage tank and the material extraction pump in sequence The outside of the mixing and preparing tank is provided with a steam heating jacket, and the top of the mixing and preparing tank is provided with a feed hopper for auxiliary agent and ESO input, and the pump is connected to the discharge port of the mixing and preparing tank, and the A liquid storage tank is attached to the extruder barrel. A circulation pipe is connected between the mixing preparation tank and the material pump, and a ball valve on the circulation pipe is installed on the circulation pipe, and a ball valve on the delivery pipe is installed on the delivery pipe between the material pump and the liquid storage tank.

Embodiment 2

[0058] A method for using an additive adding device for polycarbonate, comprising the following steps:

[0059] 1. Open the nitrogen pipeline ball valve on the nitrogen pipeline to protect the ESO prefabricated tank with nitrogen; open the steam pipeline ball valve, steam pipeline pneumatic valve and steam condensate ball valve on the steam pipeline to heat up the mixing preparation tank; open the pumping pump The heating belt of the transmission pipeline heats up the pipeline;

[0060] 2. Open the feeding hopper of the mixing preparation tank, put ESO and additives into the mixing preparation tank one after another, and obtain a mixture of additives and ESO after mixing and preparing;

[0061] 3. Stir the mixed solution obtained in step 2 while heating, and the heating temperature is maintained at 50°C; the mixing and preparation time of the additive and ESO is 2.5 hours;

[0062] 4. The auxiliary agent solution obtained in step 3 is self-circulated;

[0063] 5. Open the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com