Combined type online oil liquid bubble removal device

A composite, oil technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve difficulties and other problems, and achieve the goal of accelerating bubble accumulation, improving separation effect, and improving oil and gas separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

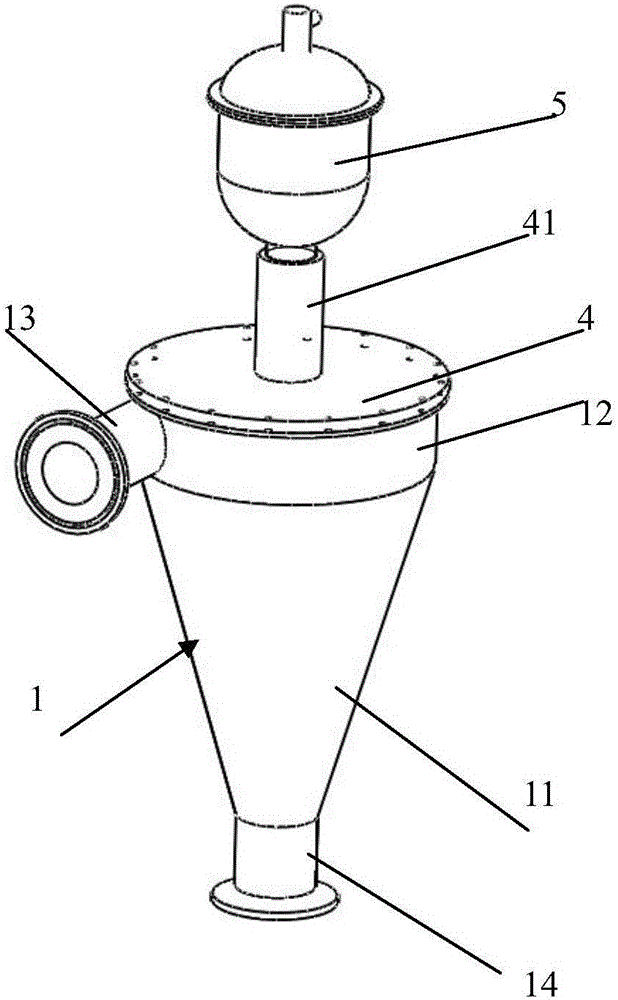

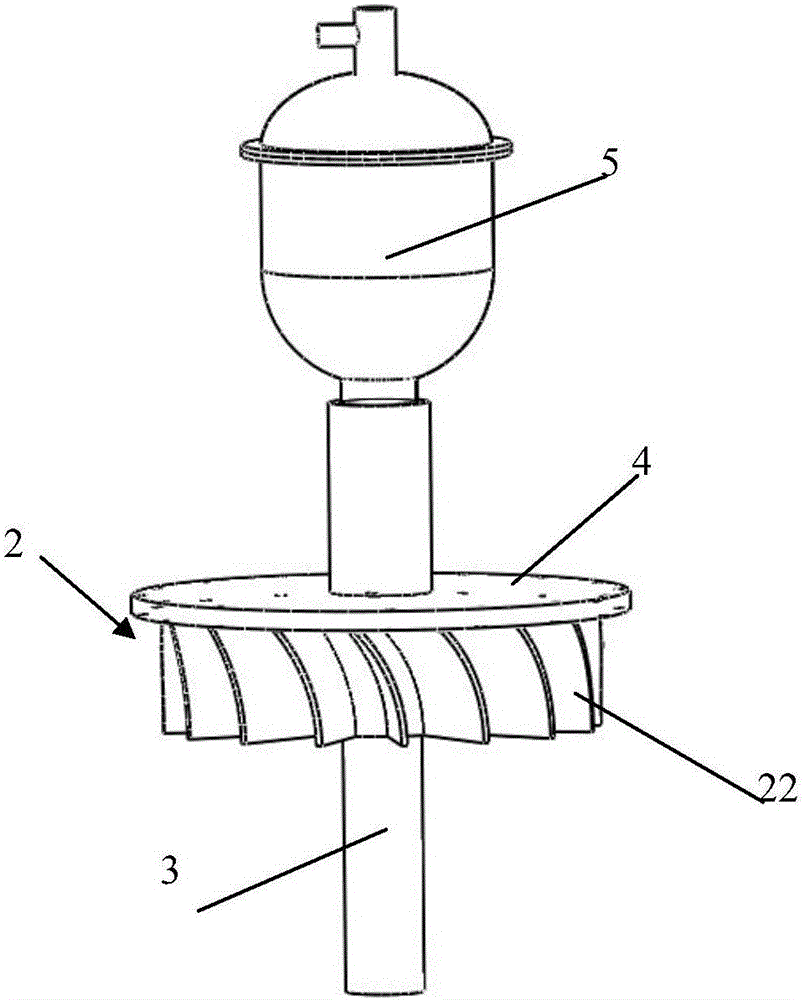

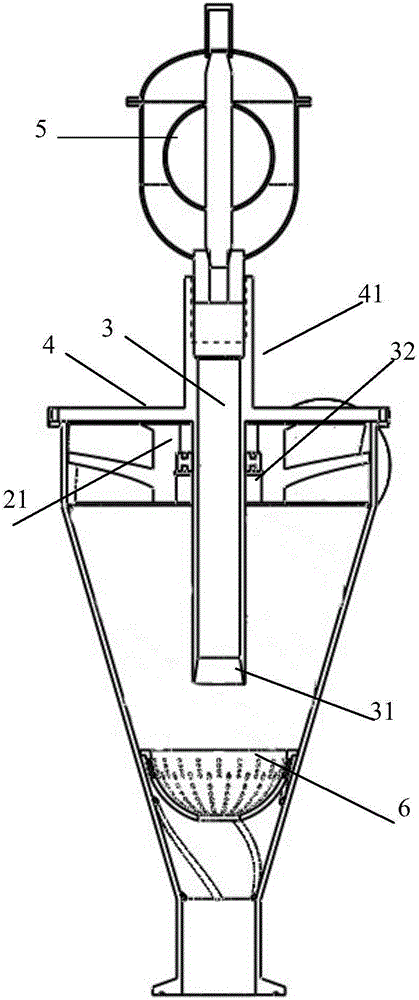

[0024] like Figure 1-4 As shown, the composite oil-liquid online debubbling device of the present invention comprises an oil-gas separation cylinder 1, a guide impeller 2, an air outlet pipe 3, an upper cover 4 that closes the opening on the oil-gas separation cylinder, and a The trachea is on the upper pipe and can automatically exhaust the exhaust valve 5. The oil and gas separation cylinder includes a cylindrical rotating cavity 12 on the upper part and a conical separation cavity 11 integrally formed at the bottom of the rotating cavity coaxially. An oil inlet pipe 13 is arranged tangentially on one side of the cavity, an oil outlet 14 is formed at the bottom of the oil and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com