Noise power generator

A technology of noise power generation and power generation devices, applied in electromechanical devices, electrical components, etc., can solve the problems of narrow noise absorption frequency, low sound-to-electric conversion efficiency, and non-concentrated sound energy, achieving high power density, high energy conversion efficiency, Efficient use of noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

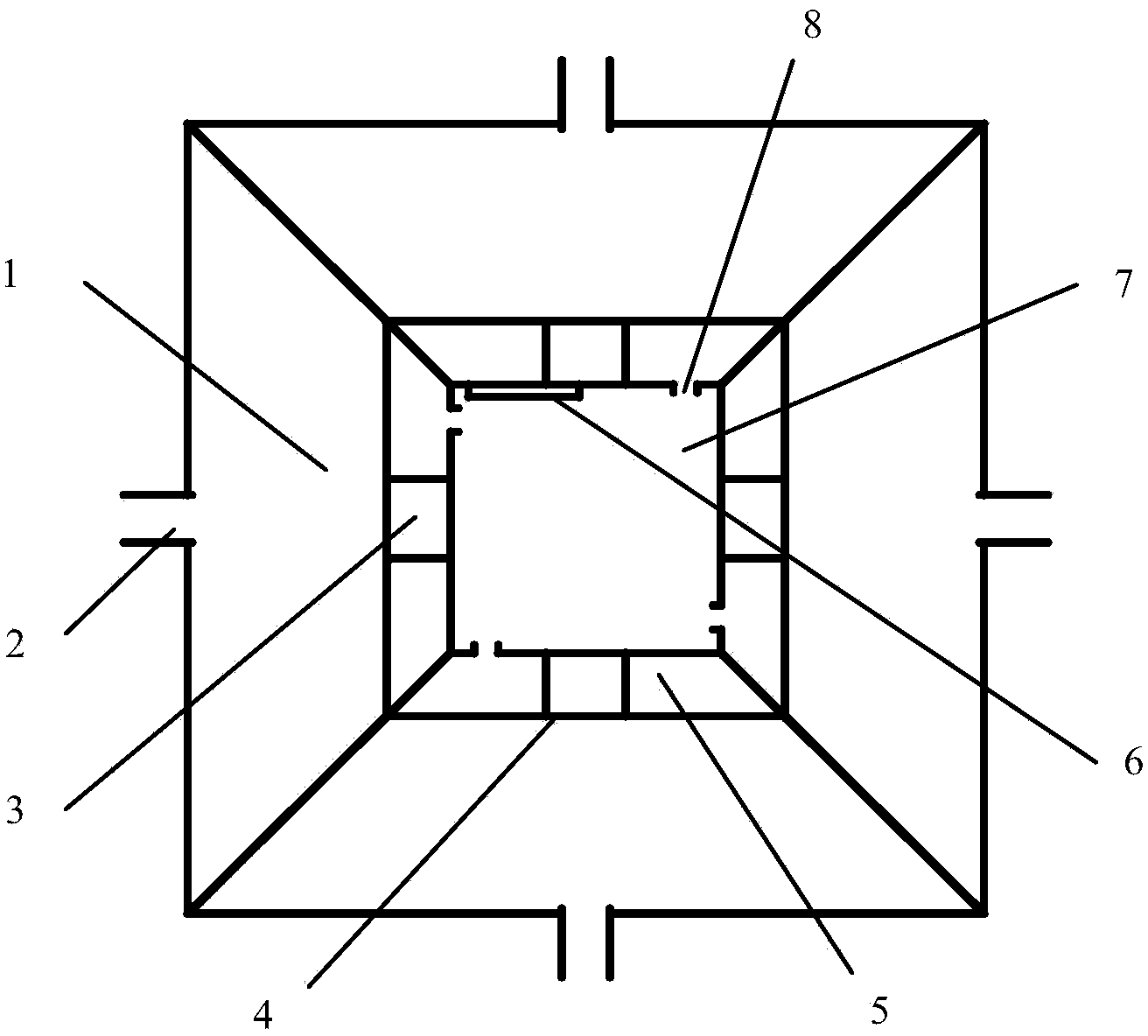

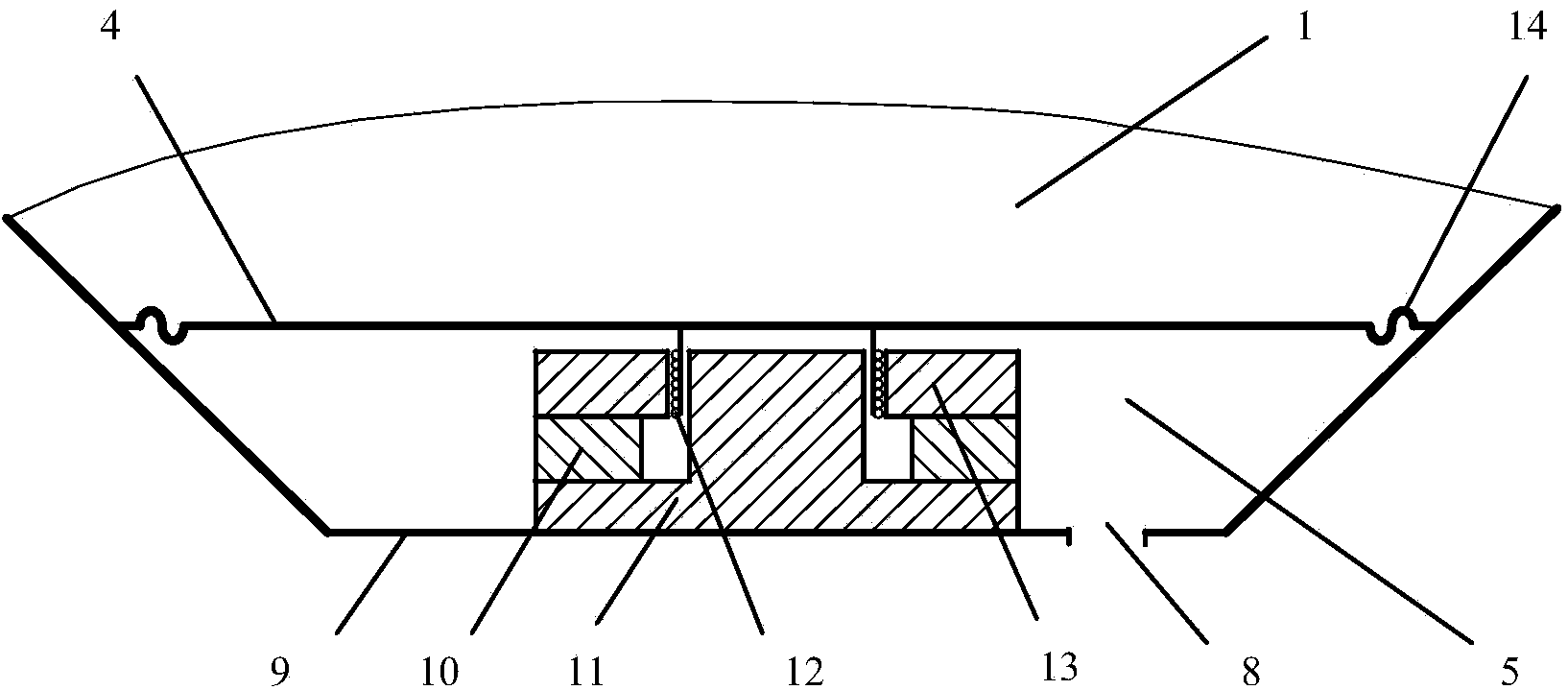

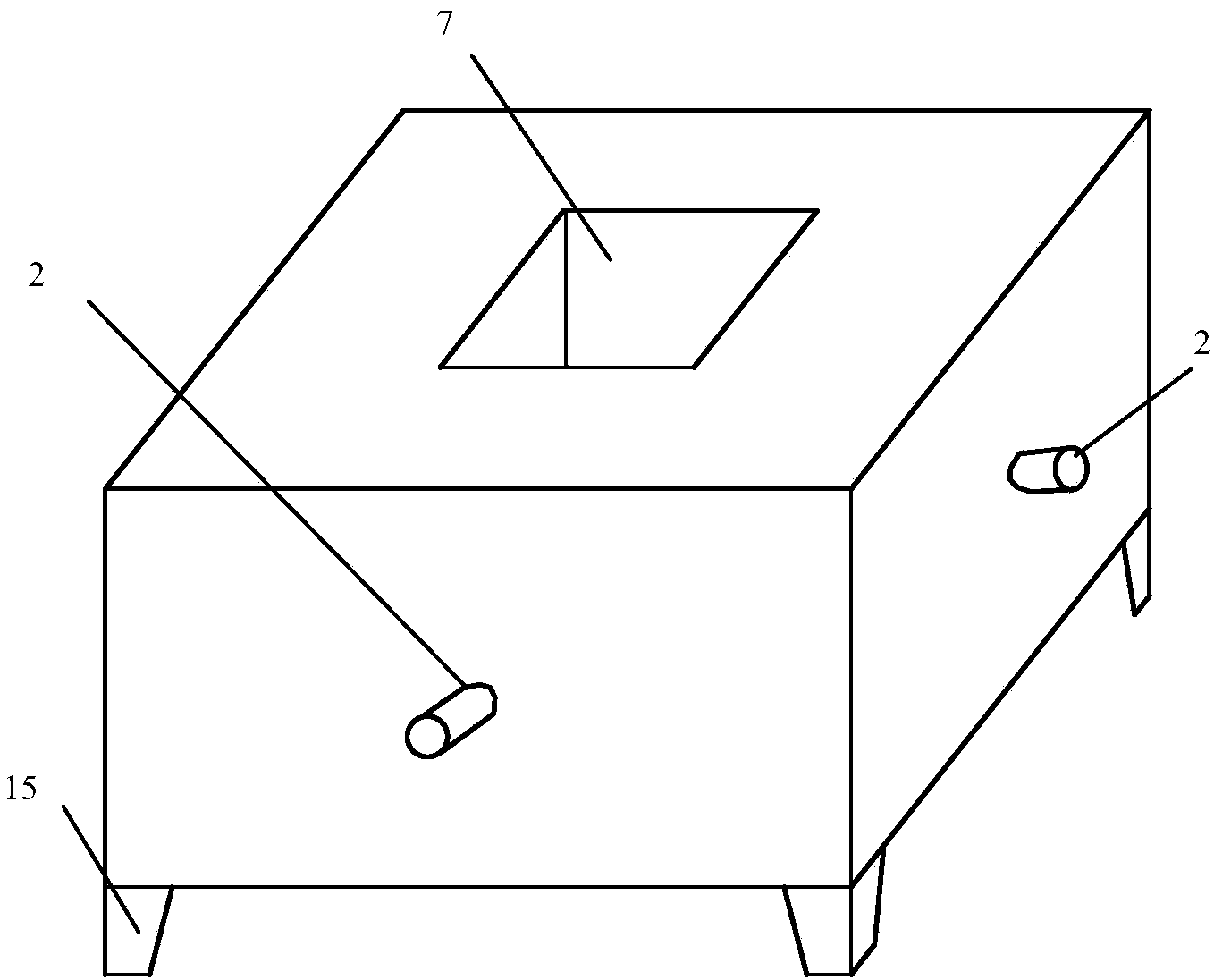

[0021] Depend on figure 1 and 2 It can be seen that the noise power generation device of the present invention has four similar structural units, and each structural unit includes a Helmholtz cavity 1, a conduit 2, a power generation device 3, an elastic wall 4, a rear chamber 5, a circuit board 6, an inner cavity 7, Inverting hole 8, rear wall 9, said Helmholtz chamber 1 communicates with the outside world through catheter 2, elastic wall 4 is placed inside Helmholtz chamber 1, and folds are arranged at both ends of said elastic wall 4 The ring 14 is also connected to the rigid side wall of the Helmholtz chamber 1. The rear chamber 5 is located at the rear of the Helmholtz chamber 1 and is isolated from each other by the elastic wall 4. The power generation device 3 is arranged in the rear chamber 5. On the rear wall 9 There is a phase-inversion hole 8 through which the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com