Ammonia water absorption refrigerator used in boat and drove by residual heat of ship engine exhaust

An exhaust waste heat and engine technology, which is applied in the direction of refrigerators, refrigeration and liquefaction, and machine operation methods, can solve problems such as deterioration of work performance and failure to operate, and achieve the effects of reducing costs and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

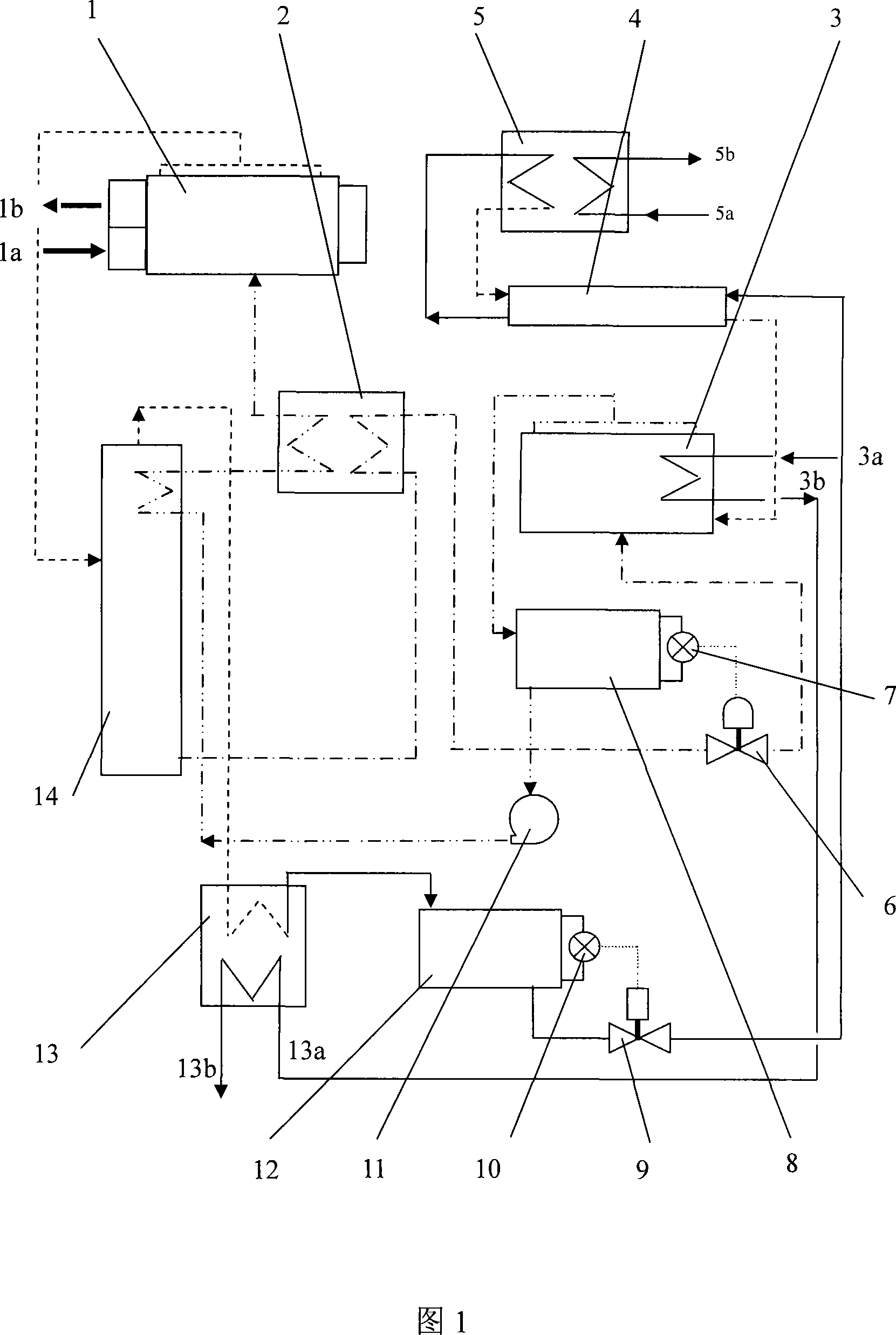

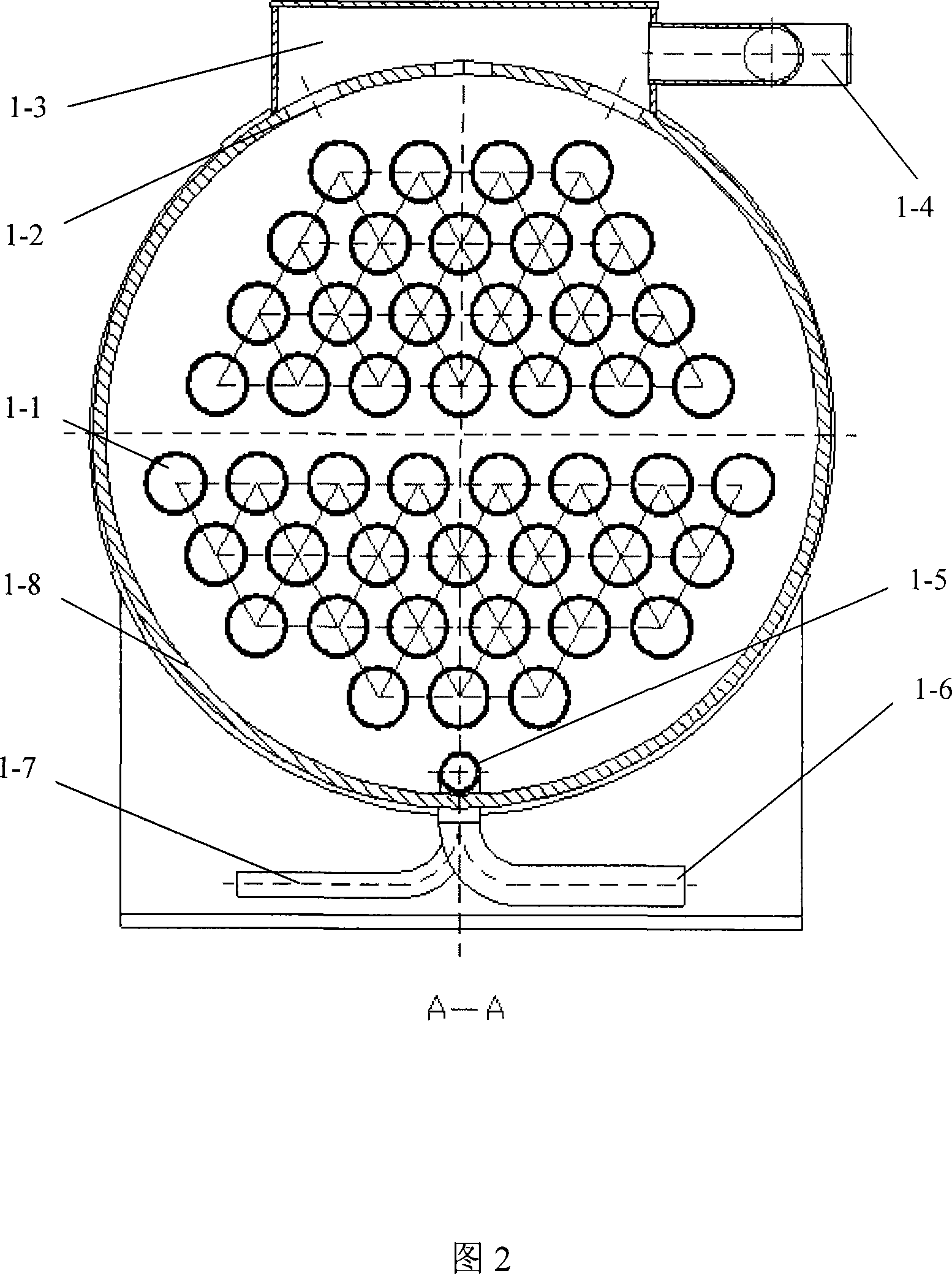

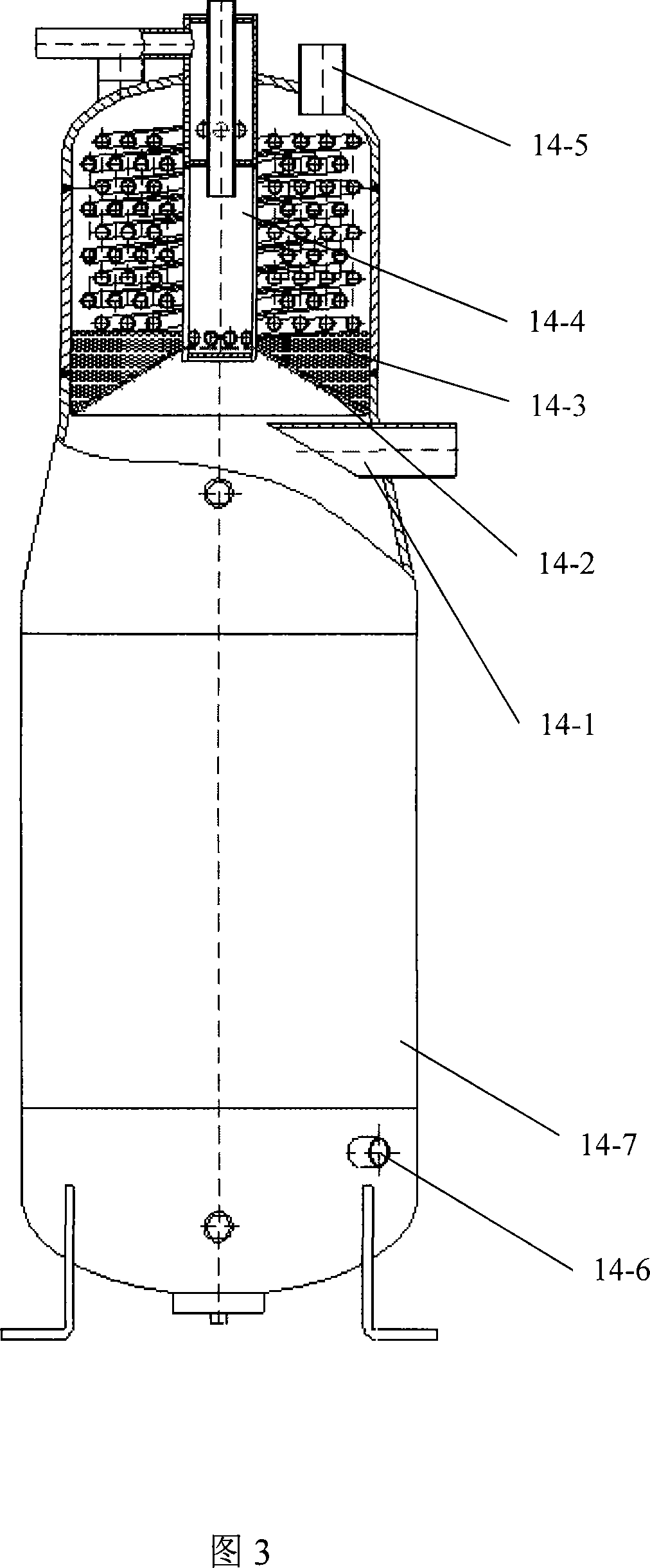

[0013] Accompanying drawing 1 is a working cycle flow of a marine ammonia water absorption refrigerator driven by exhaust waste heat of a ship engine, accompanying drawing 2 is a structural cross-sectional view of a flooded generator, accompanying drawing 3 is a structural diagram of a gas-liquid separation tank, and accompanying drawing 4 It is a cross-sectional view of a flooded bubbling absorber and a concentrated ammonia solution storage tank with a float level controller, and accompanying drawing 5 is a side view of a multi-core casing evaporator and an ammonia subcooler assembly.

[0014] The working process of the marine ammonia water absorption refrigerator driven by the exhaust waste heat of the marine engine is as follows: the engine exhaust streams 1a and 1b transfer heat to the flue gas pipe through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com