Enclosed type electric and hydraulic floating force driving system

A buoyancy-driven, closed technology, applied in the field of marine engineering, can solve the task of observing the underwater environment that cannot meet long-term, continuous, large-scale and large-depth tasks, limit the scope of use and application fields, and reduce the diving depth of gliding submarines and other issues, to achieve the effect of light weight, compact structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

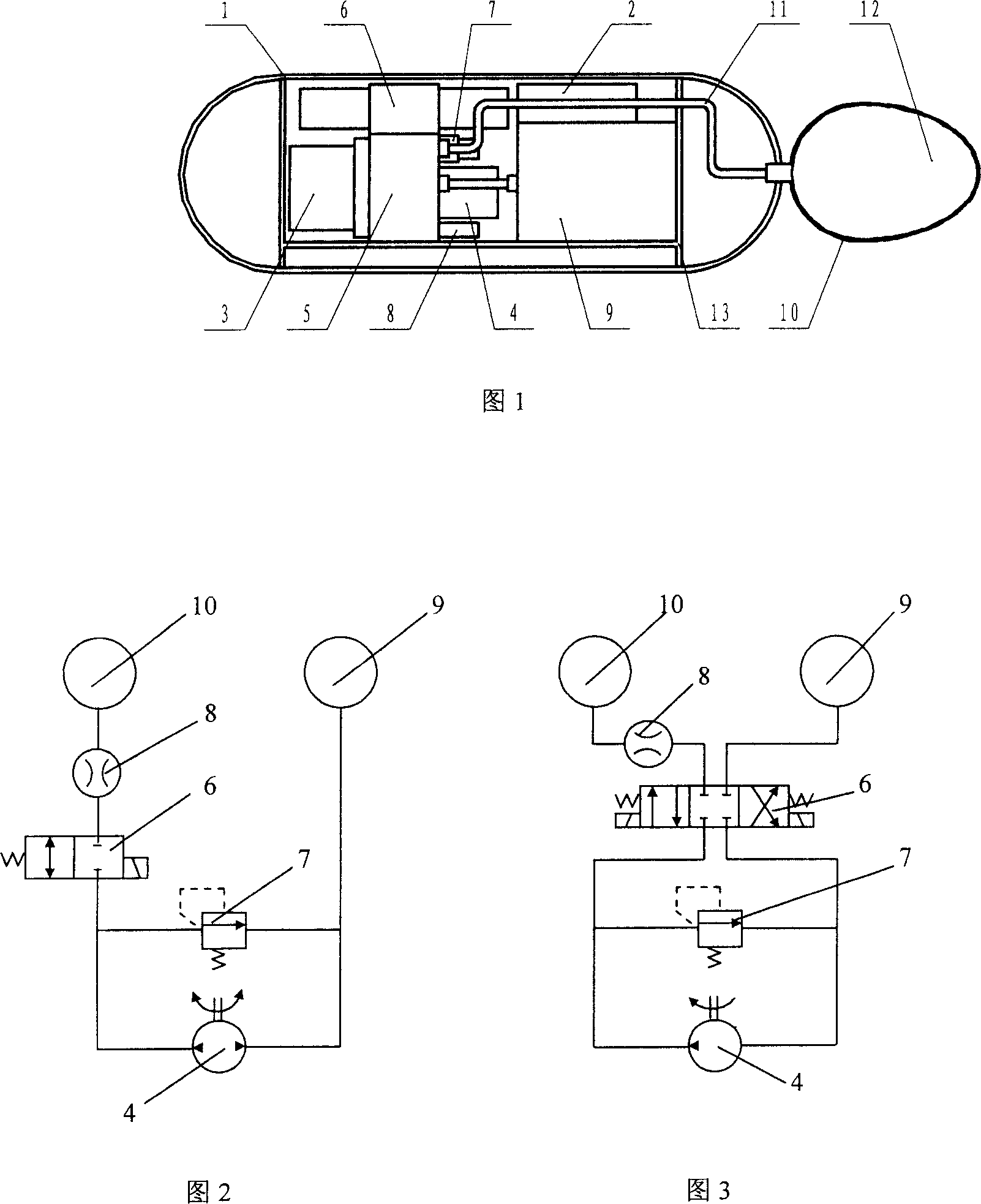

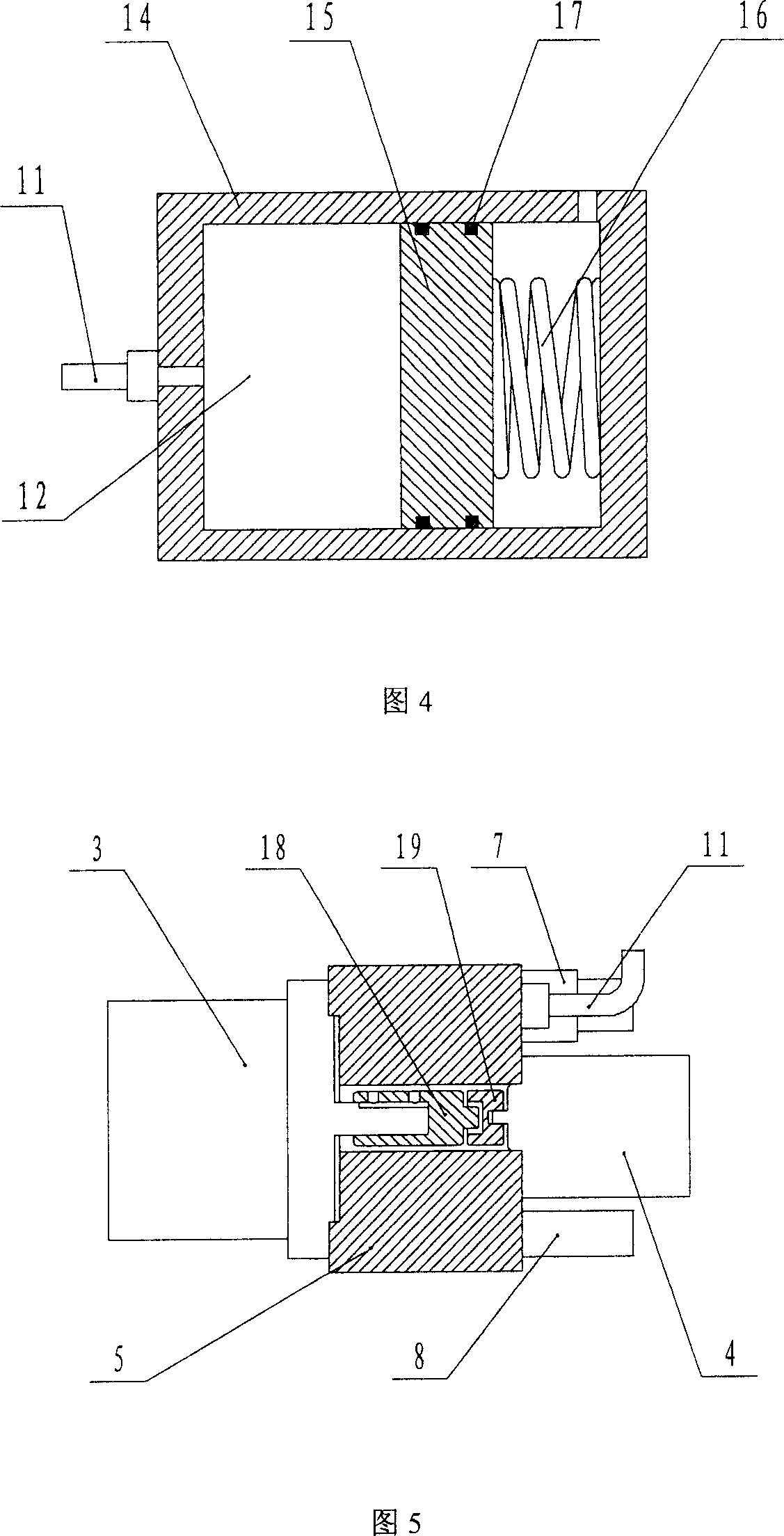

[0023] Embodiment 1: As shown in Figure 1, it includes an airtight pressure-resistant shell 1, an internal liquid medium tank 9, an external liquid medium capsule 10, and a liquid medium 12. The internal liquid medium tank 9 is located inside the airtight shell 1, and the external liquid medium capsule 10 is located outside the airtight housing 1, and is directly exposed to the external underwater environment; both the internal liquid medium tank 9 and the external liquid medium bag 10 are equipped with a liquid medium 12, which are communicated through a liquid medium pipeline 11, and the liquid medium 12 can be It flows between the internal liquid medium tank 9 and the external liquid medium bag 10. On the liquid medium pipeline 11, a hydraulic pump 4, a cut-off electromagnetic reversing valve 6, an overflow valve 7 and a flow meter 8 are integrated. On the integrated hydraulic block 5, the liquid medium pipeline 11 in the integrated hydraulic block 5 is connected. The integr...

Embodiment 2

[0031] Embodiment 2: Its structure is as shown in Figure 1, is identical with embodiment 1. The hydraulic pump 4 in this example adopts a one-way pump, and the cut-off electromagnetic reversing valve 6 is a three-position four-way valve without leakage. The specific pipeline connection relationship is shown in Figure 3: its pipeline connection relationship: hydraulic pump 4 The outlets of the valves are respectively connected with one port of the cut-off electromagnetic reversing valve 6 and the inlet of the overflow valve 7, and are connected with the external liquid medium bag 10 through the cut-off electromagnetic reversing valve 6 and the flow meter 8, and the inlets of the hydraulic pump 4 are respectively connected with the The outlet of the overflow valve 7 is connected to the other port of the cut-off electromagnetic reversing valve 6 , and is connected to the internal liquid medium tank 9 through the cut-off electromagnetic reversing valve 6 . This structure can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com