Method to generate micro scale gas filled liquid bubbles as tracer particles or inhaler mist for drug delivery

a gas filled, micro-scale technology, applied in the direction of combustion gas purification/modification, machines/engines, other medical devices, etc., can solve the problems of unstable bubbles made with pure liquid alone, and it is difficult to manufacture a frame with small orifices to reliably generate the desired size and shape of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Air Compressor Device

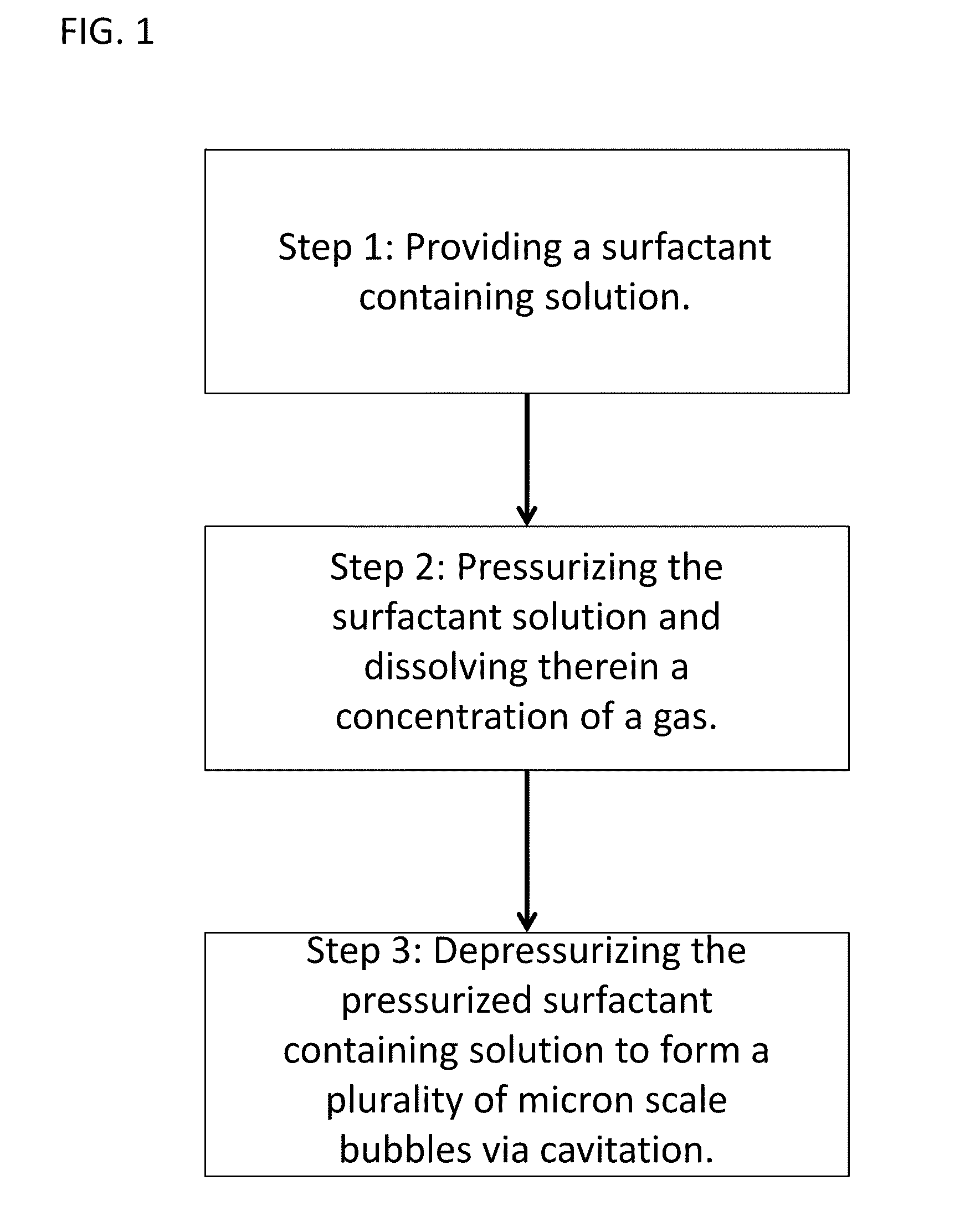

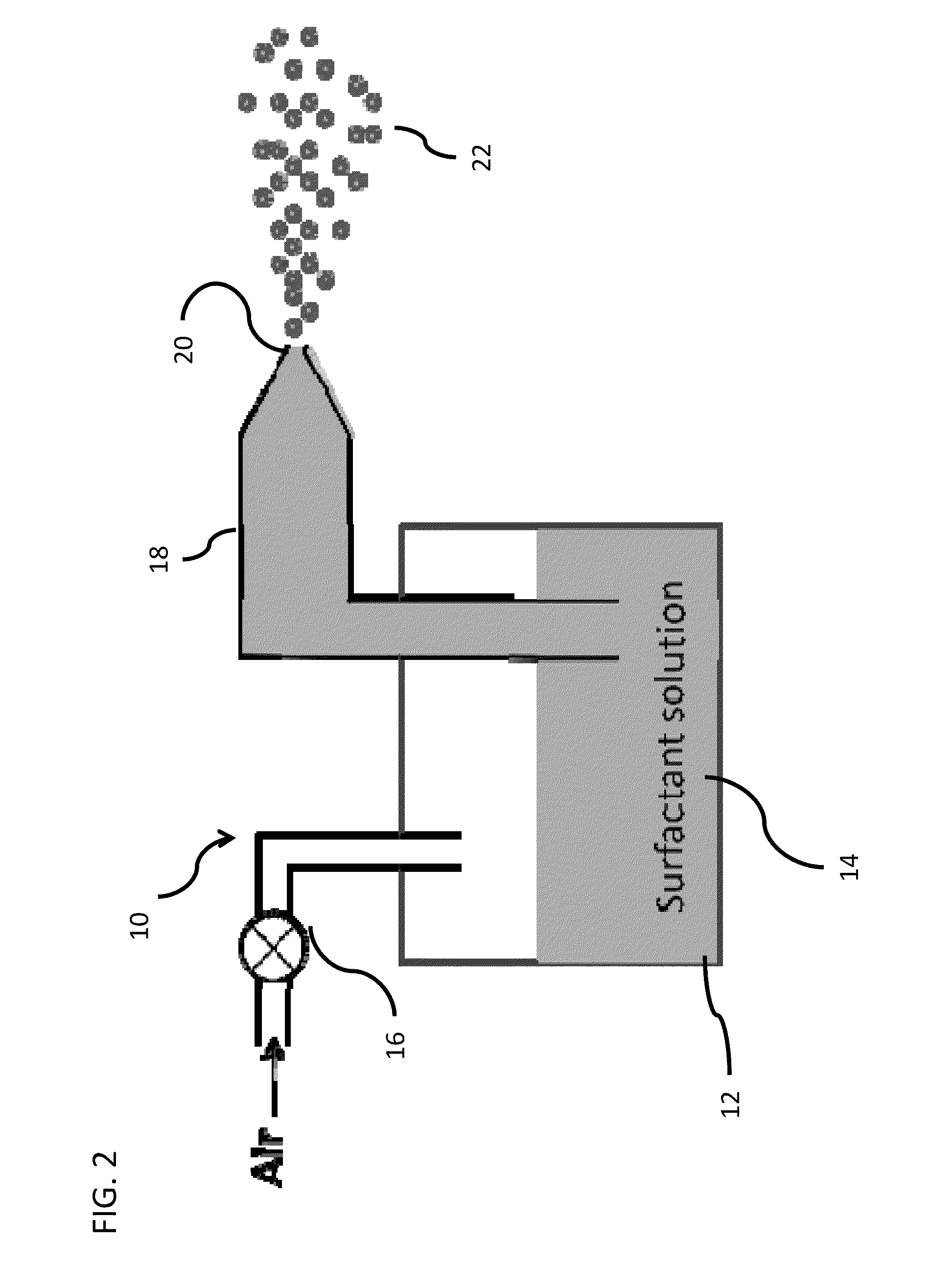

[0033]FIG. 2 shows a schematic of a spray nozzle bubble generation system in accordance with the current invention. As discussed above, while this example provides an embodiment of the invention, it should be understood that other apparatuses that incorporate the pressurizing and depressurizing system described above would be incorporated into this invention, and that this specific embodiment is provided only to demonstrate the feasibility of the inventive system in producing neutrally buoyant bubbles in the 10 micron size range.

[0034]As shown in the diagram of FIG. 2, in this embodiment the bubble generation device (10) of the instant invention comprises a reservoir (12) for containing a surfactant solution (14) that can be pressurized to a desired level. By pressurizing the solution air is forced into the solution in accordance with Henry's Law:

p=kHc EQ. 2

where p is the partial pressure of the solute in the gas above the solution, c is the concentration of th...

example 2

Pneumatic Piston Device

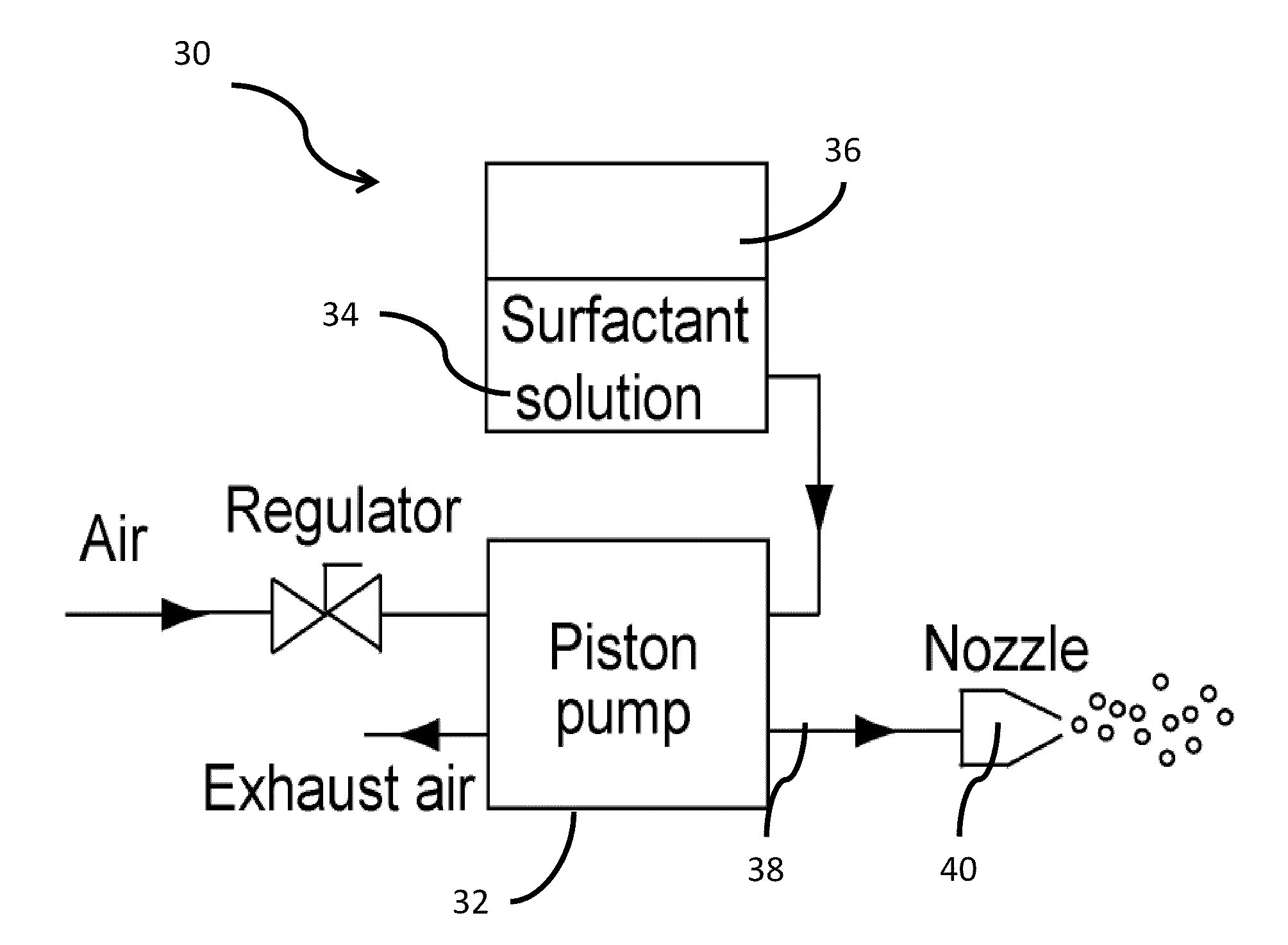

[0038]Although one embodiment of the invention is provided above, it should be understood that other methods of pressurizing and depressurizing the surfactant solution may be developed. For example, FIG. 3 provides a schematic of another embodiment of the bubble-generator (30). In this embodiment, a pneumatic driven piston pump (32) (M-series, Haskel Inc.) pressurizes soap solution (34). The soap solution in a reservoir tank (36) enters the liquid inlet (38) of the piston pump, and it is pressurized by the piston pump. When the pressurized solution passes through a misting nozzle (40) having a specific orifice size, it is atomized by an atomizer inside the nozzle and depressurized by a constricting area of the nozzle.

[0039]As before, the mechanism of bubble generation for this device is a cavitation process in liquid media. The basic concept is the rapid depressurization of an already pressurized liquid containing a desired amount of surfactant below its vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com