Sampler

A technology of sampler and sampling ring, which is applied in the direction of sampling device, etc., can solve the problems of no horizontal sampling, difficult to clean the sample, laborious operation, etc., and achieve the effects of reduced disturbance, reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

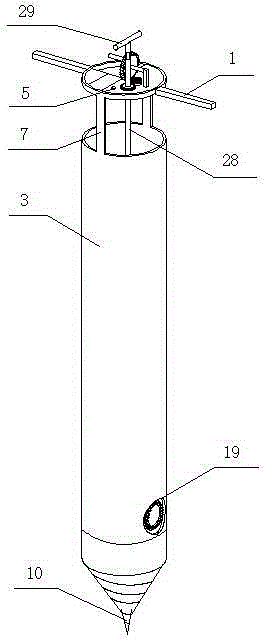

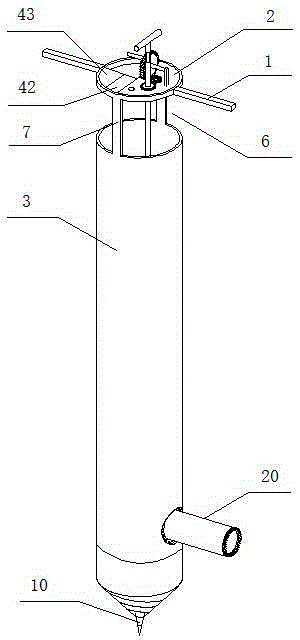

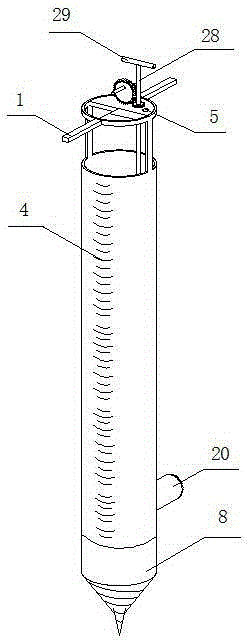

[0049] Embodiment 1: as Figure 1-15 As shown, a sampler includes a handle 1, an operating platform 2, an external drill barrel 3, a height scale 4, a small horizontal bubble 5, a sampling tank 6, a vertical shaft 7, a drill bit 8, a drill bit sampling hole 11, and a rotating buckle 12. Longitudinal sampling ring knife 13, tab slot 18, horizontal sampling hole 19, horizontal sampling ring knife 20, serration 21, piston tail piece 22, tail protruding piece 23, screw thread 24, bottom rotating gear 25, bottom control gear 26. Bottom rotating gear fixed shaft 27, sampling rod 28, sampling rod handle 29, sampling rod moving groove 30, sliding key 31, spring bead 32, spring bead slot 33, direction changing gear 34, lateral control gear 35, longitudinal adjustment Gear 36, longitudinal adjustment gear handle 37, longitudinal adjustment gear fixed shaft 38, compaction sensor 39, humidity sensor 40, wire 41, data display setting screen 42, battery 43, sample push needle 44;

[0050] ...

Embodiment 2

[0054] Embodiment 2: as Figure 1-15 As shown, a sampler includes a handle 1, an operating platform 2, an external drill barrel 3, a height scale 4, a small horizontal bubble 5, a sampling tank 6, a vertical shaft 7, a drill bit 8, a drill bit sampling hole 11, and a rotating buckle 12. Longitudinal sampling ring knife 13, tab slot 18, horizontal sampling hole 19, horizontal sampling ring knife 20, serration 21, piston tail piece 22, tail protruding piece 23, screw thread 24, bottom rotating gear 25, bottom control gear 26. Bottom rotating gear fixed shaft 27, sampling rod 28, sampling rod handle 29, sampling rod moving groove 30, sliding key 31, spring bead 32, spring bead slot 33, direction changing gear 34, lateral control gear 35, longitudinal adjustment Gear 36, longitudinal adjustment gear handle 37, longitudinal adjustment gear fixed shaft 38, compaction sensor 39, humidity sensor 40, wire 41, data display setting screen 42, battery 43, sample push needle 44;

[0055] ...

Embodiment 3

[0058] Embodiment 3: as Figure 1-15 As shown, a sampler includes a handle 1, an operating platform 2, an external drill barrel 3, a height scale 4, a small horizontal bubble 5, a sampling tank 6, a vertical shaft 7, a drill bit 8, a drill bit sampling hole 11, and a rotating buckle 12. Longitudinal sampling ring knife 13, lug slot 18, horizontal sampling hole 19, horizontal sampling ring knife 20, sawtooth 21, piston tail piece 22, tail protruding piece 23, screw thread 24, bottom rotating gear 25, bottom control gear 26. Bottom rotation gear fixed shaft 27, sampling rod 28, sampling rod handle 29, sampling rod moving slot 30, sliding key 31, spring bead 32, spring bead slot 33, direction changing gear 34, lateral control gear 35, longitudinal adjustment Gear 36, longitudinal adjustment gear handle 37, longitudinal adjustment gear fixed shaft 38, compaction sensor 39, humidity sensor 40, wire 41, data display setting screen 42, battery 43, sample push needle 44;

[0059]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com