Method for making nano-powder through ultrasonic atomization-microwave pyrolysis

A nano-powder, ultrasonic technology, applied in chemical instruments and methods, oxide/hydroxide preparation, nanotechnology and other directions, can solve the problem of high energy consumption, achieve good quality, simple process route, fast and stable reaction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for preparing nano powder by ultrasonic atomization-microwave pyrolysis, its specific steps are as follows:

[0027] (1) Firstly, the soluble easily decomposable metal salt and water and ethanol solution are configured to form a precursor solution, wherein the volume ratio of water and ethanol solution is 100:0, and the molar concentration of the soluble metal salt in the precursor solution is 0.001mol / L, The soluble metal salt is zinc acetate;

[0028] (2) Ultrasonic atomization of the precursor solution prepared in step (1) to obtain droplets with an average diameter of 10 μm;

[0029] (3) Under the action of carrier gas or fan, the droplets prepared in step (2) are brought into the microwave, and quickly dried and pyrolyzed at 450°C to prepare nano-shell zinc oxide powder.

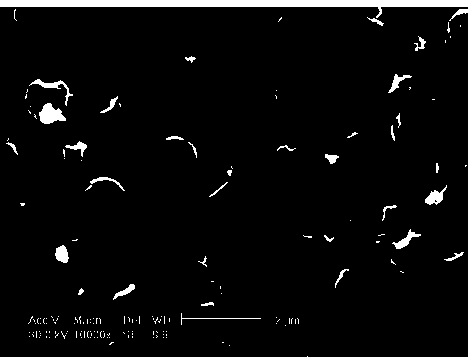

[0030] The shell thickness of the above-mentioned nano-shell metal oxide powder is about 10nm, the particles are uniformly distributed, and the dispersion is good, such as figure 1 s...

Embodiment 2

[0032] The method for preparing nano powder by ultrasonic atomization-microwave pyrolysis, its specific steps are as follows:

[0033] (1) Firstly, the soluble easily decomposable metal salt and water and ethanol solution are configured into a precursor solution, wherein the volume ratio of water and ethanol solution is 80:20, and the soluble easily decomposable metal salt is 2.16g of InCl 3 .5H 2 O and 0.19 g of SnCl 2 .2H 2 O;

[0034] (2) Ultrasonic atomization of the precursor solution prepared in step (1) to obtain droplets with an average diameter of 100 μm;

[0035] (3) Under the action of carrier gas or fan, the mist prepared in step (2) is brought into the microwave, and quickly dried and pyrolyzed at 700 ° C to prepare nano-ITO powder.

Embodiment 3

[0037] The method for preparing nano powder by ultrasonic atomization-microwave pyrolysis, its specific steps are as follows:

[0038] (1) Firstly, the soluble easily decomposable metal salt and water and ethanol solution are configured into a precursor solution, wherein the volume ratio of water and ethanol solution is 70:30, and the soluble easily decomposable metal salt is 2.25g of SbCl 3 and 6.75g of SnCl 2 .2H 2 O;

[0039] (2) Ultrasonic atomization of the precursor solution prepared in step (1) to obtain droplets with an average diameter of 100 μm;

[0040] (3) Under the action of carrier gas or fan, the droplets prepared in step (2) are brought into the microwave, and quickly dried and pyrolyzed at 600°C, the composite metal of nano-antimony oxide doped tin oxide can be prepared oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com