Converter tapping injection refining desulfurization method and device

A desulfurization device and converter technology, applied in the field of secondary refining of steel, can solve the problems of large consumption of slag-forming materials and heat, low interphase mass transfer rate, small contact specific surface area, etc. low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

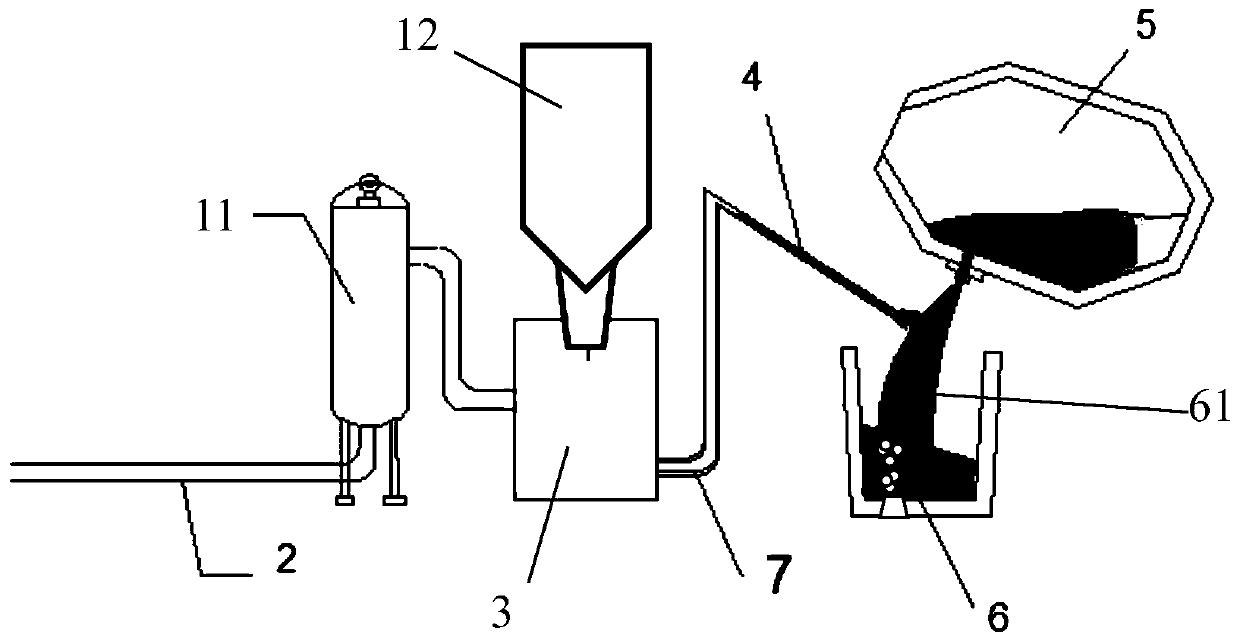

[0050] Such as figure 1 As shown, it is a schematic diagram of the overall composition of the converter tapping powder spraying refining desulfurization device in Example 1 of the present invention. The figure includes a gas storage tank 11, a powder injection station 3, a powder tank 12, a connecting pipeline 2, a spray gun 4, a blowing pipeline 7, a converter 5, and a ladle 6.

[0051] Among them, the gas storage tank 11, the powder injection station 3, the powder material tank 12, the connecting pipeline 2, the spray gun 4, and the injection pipeline 7 constitute the converter tapping powder spraying refining desulfurization device according to the embodiment 1 of the present invention.

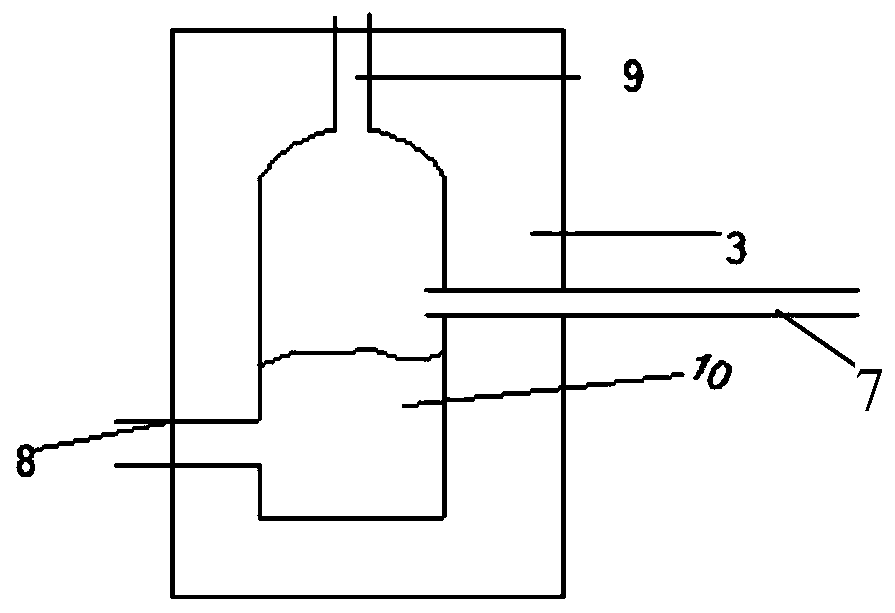

[0052] Wherein the gas storage tank 11 is used to store gas, such as Ar or N 2 or a mixture of both. Powder tank 12 is used for powdery desulfurizers, such as refined desulfurization powder, carbon powder, dephosphorization powder and alloy powder. combine figure 2 As shown, the powde...

Embodiment 2

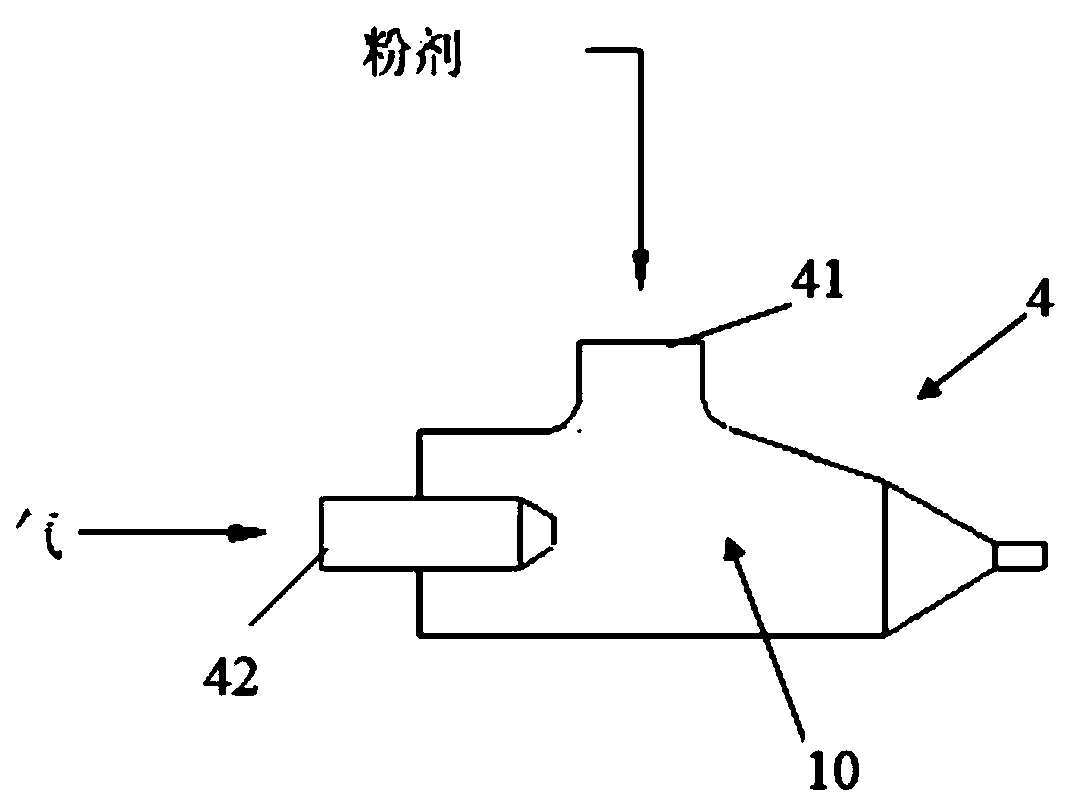

[0060] Such as image 3 As shown, it is another embodiment of the converter tapping powder spraying refining desulfurization device of the present invention. The difference between this embodiment and Embodiment 1 is that: this embodiment does not set the powder spray stick 3 , but sets the powder gas mixing fluidization chamber in the spray gun 4 . The spray gun 4 is provided with a powder inlet 41 and a gas inlet 42, the powder inlet 42 is connected to the powder tank, and the gas inlet 42 is connected to the gas storage tank through a gas supply pipeline. Thereby, the powdery desulfurizing agent and the gas are premixed and fluidized in the spray gun 4 , and then sprayed from the nozzle of the spray gun 4 .

[0061] Further, the spray gun 4 is a double-layer casing with a heat insulating layer, the outer layer is a heat insulating layer, and the inner layer is a spray gun tube of high-temperature-resistant ceramics. The inner diameter of the spray gun tube is 12-50mm, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com