Double-alkaline semi-dry flue gas desulfurization device and technique thereof

A technology of desulfurization device and semi-dry method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high operating costs and low desulfurization efficiency, and achieve low operating costs, small consumption, and water-soluble Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

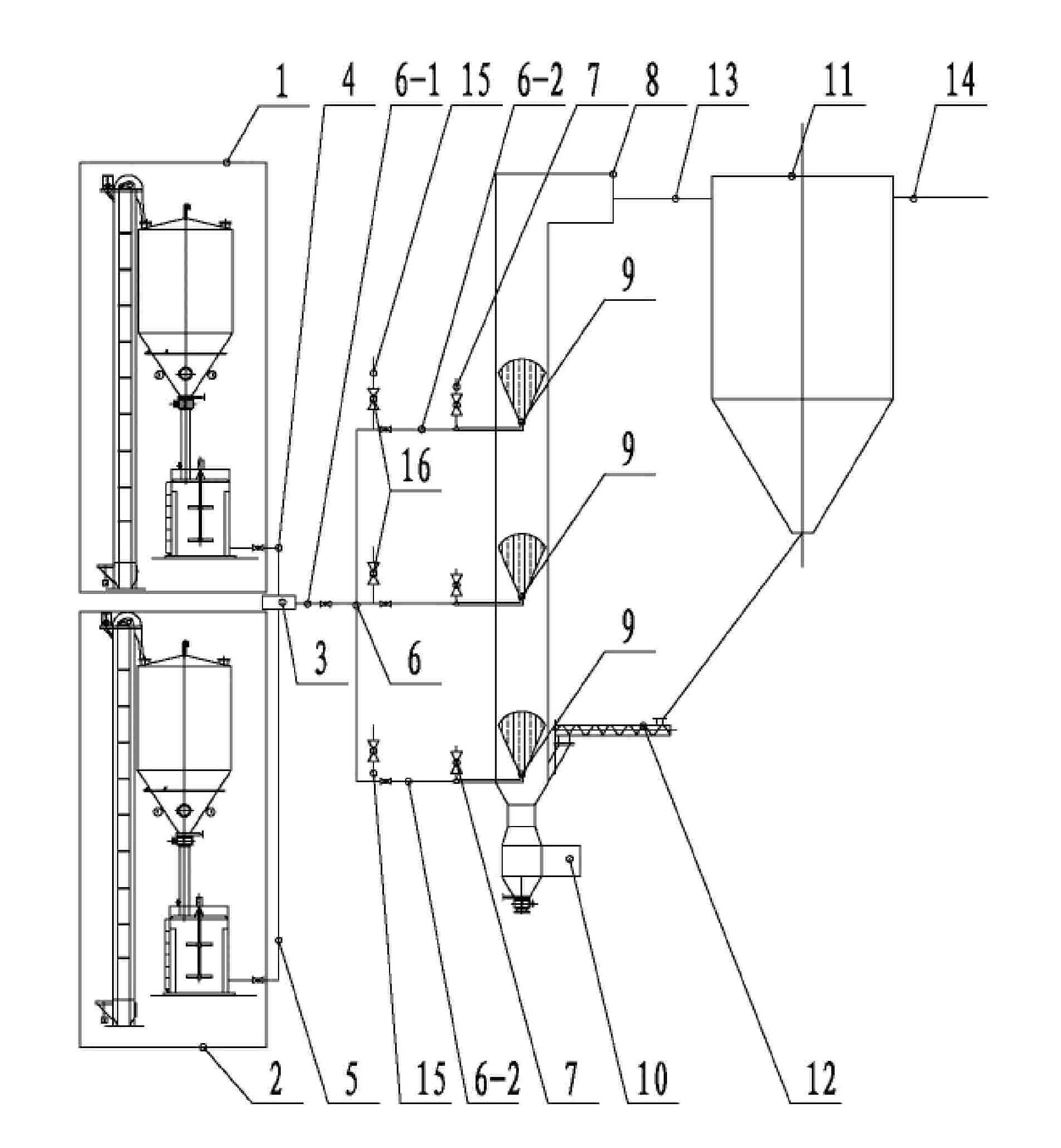

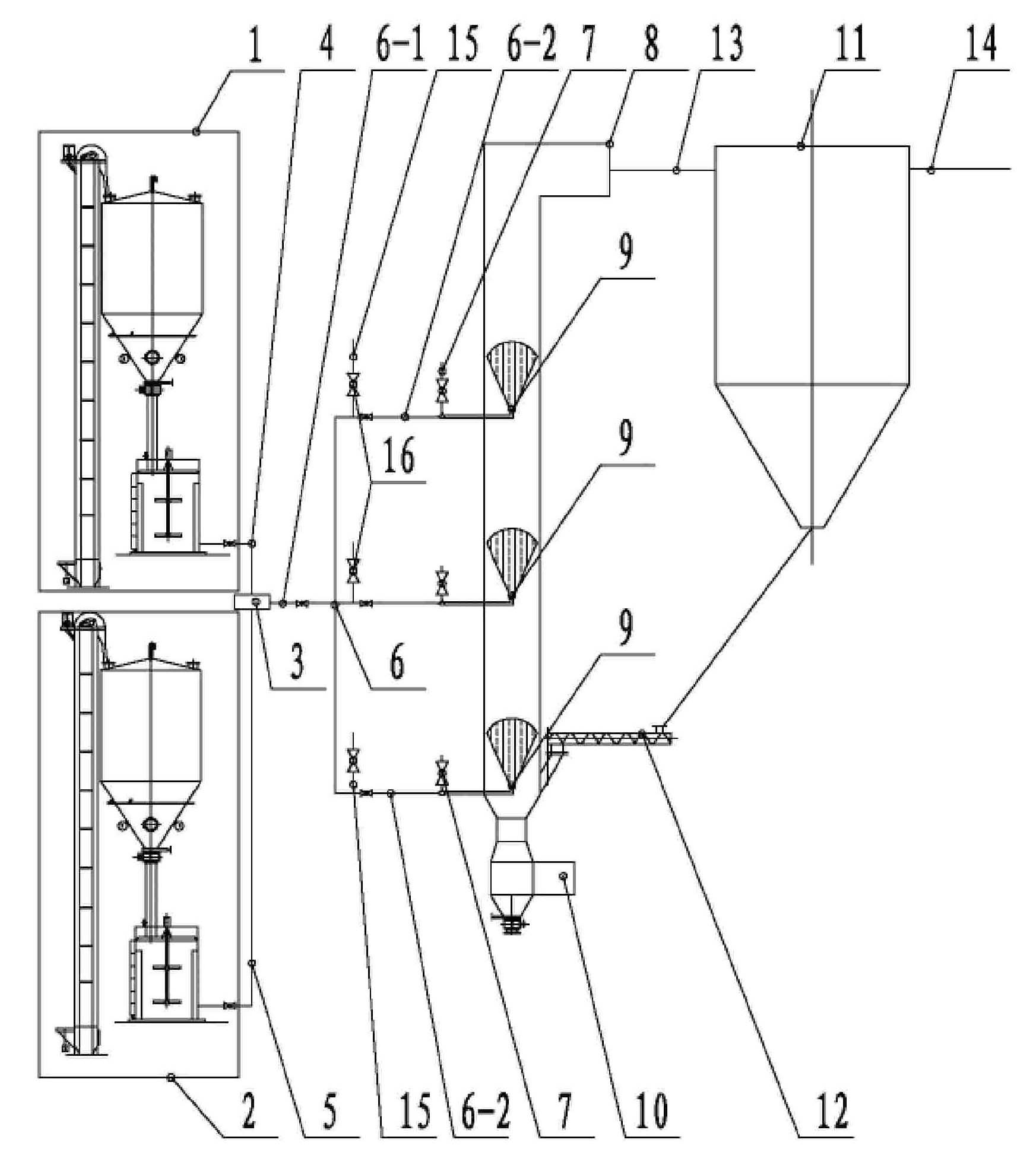

[0019] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the first desulfurization device of this embodiment includes a slaked lime slurry preparation device 1, a caustic soda solution preparation device 2, a mixed slurry preparation device 3, a slaked lime slurry pipe 4, a caustic soda solution pipe 5, a mixed slurry pipe 6, and a desulfurization tower 8. Multiple atomizing nozzles 9, dust removal equipment 11, material conveyor 12, gas flow pipe 13, exhaust pipe 14 and multiple pressure pipes with gas control valves matching the number of atomizing nozzles 9 7. The hydrated lime slurry preparer 1 communicates with the mixed slurry preparer 3 through the slaked lime slurry pipe 4, the caustic soda solution preparer 2 communicates with the mixed slurry preparer 3 through the caustic soda solution pipe 5, and the plurality of atomizing nozzles 9 Arranged in the desulfurization tower 8 along the height direction of the desulfurization tower 8, the...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that the desulfurization device also has a plurality of process water supply pipes 15 and a plurality of valves 16, and the number of process water supply pipes 15 and valves 16 is the same as that of the branch pipe 6-2 The number of each process water supply pipe 15 is installed on the corresponding branch pipe 6-2 and communicated with the branch pipe 6-2. A valve 16 is installed on each process water supply pipe 15. Such setting facilitates the adjustment of the mass concentration of the mixed slurry. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

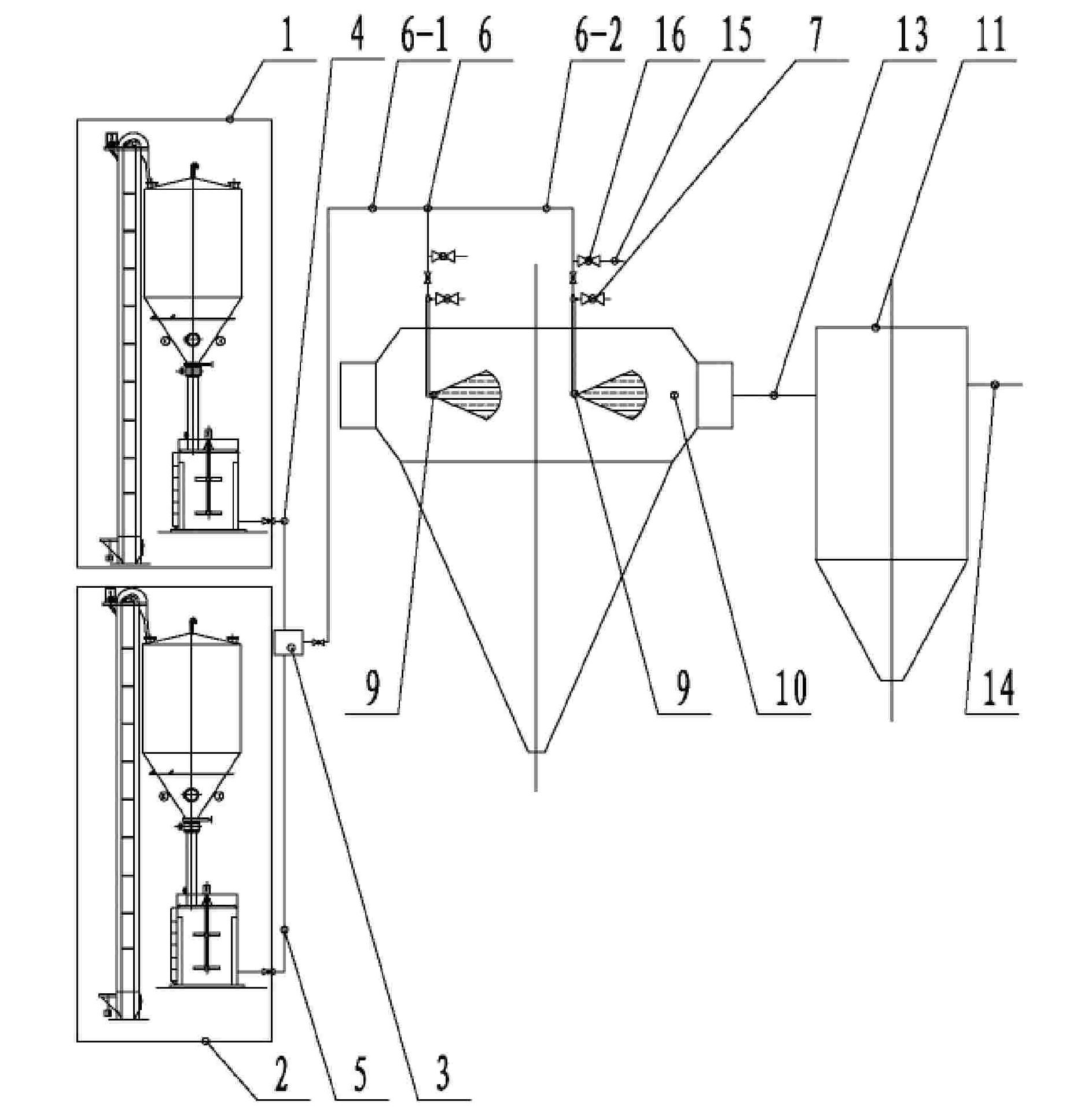

[0021] Specific implementation mode three: combination figure 2To illustrate this embodiment, the second desulfurization device of this embodiment includes a slaked lime slurry preparation device 1, a caustic soda solution preparation device 2, a mixed slurry preparation device 3, a slaked lime slurry pipe 4, a caustic soda solution pipe 5, a mixed slurry pipe 6, a plurality of Atomizing nozzle 9, dedusting equipment 11, gas flow pipe 13, exhaust pipe 14 and a plurality of pressure pipes 7 with gas control valves matching the number of atomizing nozzles 9, the slaked lime slurry preparation device 1 The slaked lime slurry pipe 4 communicates with the mixed slurry preparation device 3, the caustic soda solution preparation device 2 communicates with the mixed slurry preparation device 3 through the caustic soda solution pipe 5, and the plurality of atomizing nozzles 9 are along the length direction of the exhaust gas pipeline 10 Arranged in the flue gas exhaust pipe 10, the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com