Supergravity SCR denitrification device and denitrification technology thereof

A technology of supergravity and supergravity rotation, which is applied in the field of SCR denitrification, can solve the problems of safety hazards in the liquid ammonia gasification process, high energy consumption, and high operating costs of the thermal decomposition of urea process, so as to shorten the gas-liquid contact time, simplify the process, The effect of increasing the gas-liquid contact specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

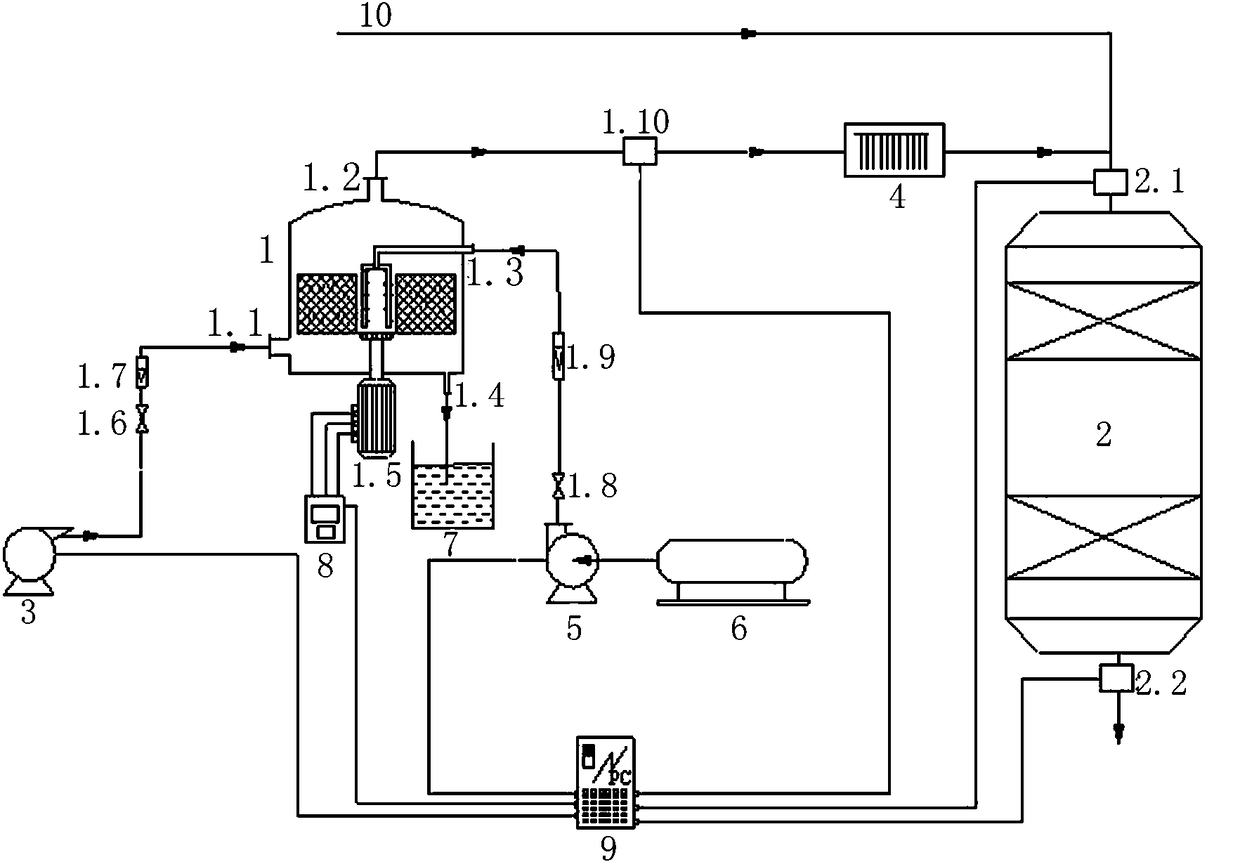

[0029] Example 1: The concentration of industrial ammonia water is 25%, and its main equipment: the supergravity rotating packing bed adopts stainless steel wire mesh packing, and the shell and storage tank of the rotating packing bed are made of 304 stainless steel. The gas-liquid contact mode is cross-flow.

[0030] First, turn on the cross-flow rotary packed bed, control its supergravity factor at 58.5 through the frequency converter 8, open the liquid valve, start the centrifugal pump 5 to send ammonia water to the supergravity rotary packed bed 1, and keep the ammonia water feed at 0.2m 3 / h, open the gas valve, adjust the gas flow meter to keep the gas-liquid ratio at 2500m 3 / m 3 , ammonia water and air contact in the filler to complete the mass transfer process; when all the ammonia water in the ammonia water raw material tank enters the supergravity rotating packed bed, close the liquid valve and liquid pump; when the liquid outlet 1.4 of the rotating packed bed is n...

Embodiment 2

[0031] Embodiment 2: change following conditions, other conditions are the same as embodiment 1. The high-gravity factor of the high-gravity rotating packed bed is adjusted to 131.7, the gas-liquid ratio is 2500, the final stripping rate can reach 85.1%, and the ammonia production concentration of the rotating packed bed is 12.9%.

Embodiment 3

[0032] Embodiment 3: change following conditions, other conditions are the same as embodiment 1. The high-gravity factor of the high-gravity rotary packed bed is adjusted to 179.2, the gas-liquid ratio is 2500, the final stripping rate can reach 85.5%, and the ammonia production concentration of the rotary packed bed is 13.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com