Catalyst for carbon dioxide reduction through electrocatalysis and preparation method thereof

A carbon dioxide and catalyst technology, which is applied in the field of electrocatalytic carbon dioxide reduction, can solve the problems of poor catalyst stability, low current efficiency, and low selectivity of target products, and achieve the effect of increasing the contact specific surface area and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

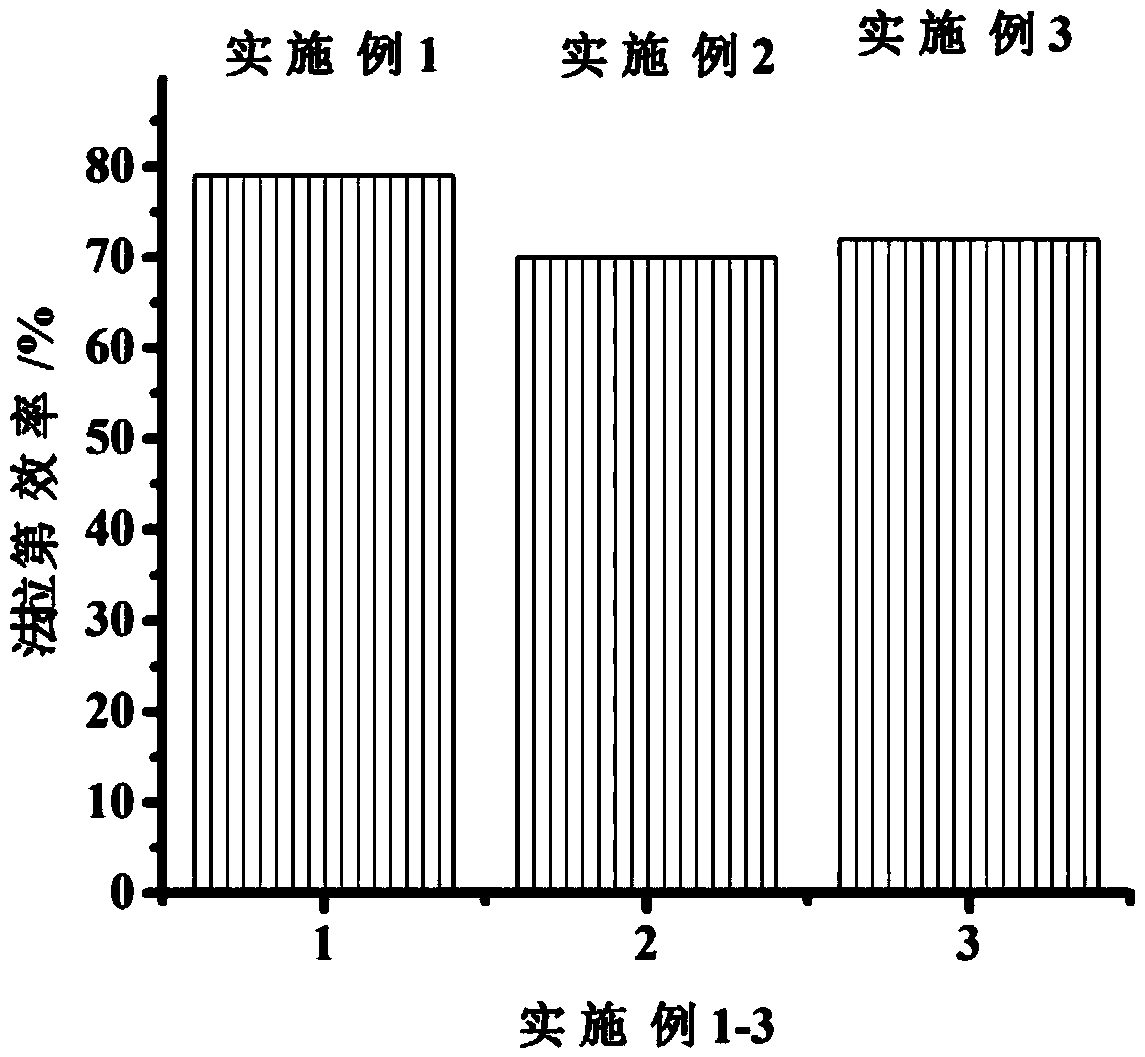

Embodiment 1

[0021] The preparation method of the catalyst for the electrocatalytic carbon dioxide reduction comprises the following steps:

[0022] (1) Preparation of fiber membrane precursor: take 1g of polyacrylonitrile and 1g of ferric nitrate in 10mL of N,N-dimethylformamide, stir for 12 hours, take a uniform solution, and use an electrospinning machine to prepare the Inhale the homogeneous solution into the syringe, install a needle of type 20, exhaust the air bubbles, set the voltage to 10KV, the flow rate to 0.02mm / min, the spinning distance to 13cm, the humidity to 20%, and the temperature to room temperature, start electrospinning, After 12h, the fiber membrane precursor was obtained;

[0023] (2) Preparation of nitrogen-doped carbon nanofiber composite iron particles: the fiber film precursor prepared in step (1) was placed in a tube furnace, and calcined in a mixed gas atmosphere composed of argon and hydrogen. The heating rate of ℃ / min is raised to 500 ℃, and the temperature ...

Embodiment 2

[0026] The preparation method of the catalyst for the electrocatalytic carbon dioxide reduction comprises the following steps:

[0027] (1) Preparation of fiber membrane precursor: take 2g of polyacrylonitrile and 2g of ferric nitrate in 20mL of N,N-dimethylformamide, stir for 24 hours, take a uniform solution, and use an electrospinning machine to prepare the Inhale the homogeneous solution into the syringe, install a needle of type 20, exhaust the air bubbles, set the voltage to 20KV, the flow rate to 0.08mm / min, the spinning distance to 20cm, the humidity to 50%, and the temperature to room temperature, start electrospinning, After 24h, the fiber film precursor is obtained;

[0028] (2) Preparation of nitrogen-doped carbon nanofiber composite iron particles: the fiber film precursor prepared in step (1) was placed in a tube furnace, and calcined in a mixed gas atmosphere composed of argon and hydrogen. The heating rate of ℃ / min is raised to 1000 ℃, and the temperature is k...

Embodiment 3

[0031] The preparation method of the catalyst for the electrocatalytic carbon dioxide reduction comprises the following steps:

[0032] (1) Preparation of fiber membrane precursor: take 1.5g of polyacrylonitrile and 1.5g of ferric nitrate in 15mL of N,N-dimethylformamide, stir for 18 hours, take a uniform solution, and use an electrospinning machine to prepare Inhale a good homogeneous solution into the syringe, install a needle of type 20, discharge air bubbles, set the voltage at 20KV, flow rate at 0.02mm / min, spinning distance at 13-20cm, humidity at 50%, and temperature at room temperature, start Electrospinning, after 24h, the fiber film precursor is obtained;

[0033] (2) Preparation of nitrogen-doped carbon nanofiber composite iron particles: the fiber film precursor prepared in step (1) was placed in a tube furnace, and calcined in a mixed gas atmosphere composed of argon and hydrogen. The heating rate of ℃ / min is raised to 800 ℃, and the temperature is kept for 3 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com