Preparation method of easy-to-clean hydrophilic and anti-fouling wig

An easy-to-clean, wig technology, applied in the direction of wigs, anti-coloring and pollution/fouling fibers, wear-resistant fibers, etc., can solve the problems of difficult removal of stains, affecting the appearance of wigs, and easy knotting, etc., to achieve enhanced electrostatic repulsion Power, improve anti-pollution performance, alleviate the effect of adsorption pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

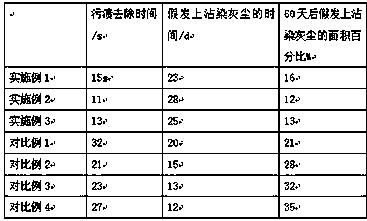

Examples

Embodiment 1

[0030] A method for preparing an easy-to-clean hydrophilic antifouling wig, the specific preparation method is as follows:

[0031] 1) Sulfonation modification of polyethersulfone

[0032] Take 5 parts of polyethersulfone, add it to 30 parts of sulfuric acid solution with a concentration of 90%, stir to dissolve it evenly, then slowly add 2 parts of chlorosulfonic acid dropwise, stir and react at 10°C at 300r / min for 2h, and dissolve the reaction After suction filtration, the final product was rinsed with distilled water until neutral, and then dried at 80°C for 2 hours to obtain sulfonated polyethersulfone;

[0033] 2) Polydopamine modified polyethersulfone

[0034] Take 5 parts of dopamine, add it to tris-hydrochloric acid buffer solution, stir and dissolve to prepare a 2.0mg / ml dopamine solution, then add the coated wig fiber into it, react at room temperature for 20h, take out Afterwards, wash with ethanol and distilled water alternately for 3 times, and dry at 50°C for ...

Embodiment 2

[0051] A method for preparing an easy-to-clean hydrophilic antifouling wig, the specific preparation method is as follows:

[0052] 1) Sulfonation modification of polyethersulfone

[0053] Take 6 parts of polyethersulfone, add it to 35 parts of sulfuric acid solution with a concentration of 95%, stir to dissolve it evenly, then slowly add 2.5 parts of chlorosulfonic acid dropwise, stir and react at 15°C at 350r / min for 1.5h, and The reacted product was suction filtered, washed with distilled water until neutral, and then dried at 90°C for 1.5 hours to obtain sulfonated polyethersulfone;

[0054] 2) Polydopamine modified polyethersulfone

[0055] Take 7 parts of dopamine, add it to tris-hydrochloric acid buffer solution, stir and dissolve to prepare a 2.5 mg / ml dopamine solution, then add the coated wig fiber into it, react at room temperature for 23 hours, take out Finally, wash with ethanol and distilled water alternately for 4 times, and dry at 55°C for 12 hours;

[0056]...

Embodiment 3

[0072] A method for preparing an easy-to-clean hydrophilic antifouling wig, the specific preparation method is as follows:

[0073] 1) Sulfonation modification of polyethersulfone

[0074] Take 7 parts of polyethersulfone, add it to 40 parts of sulfuric acid solution with a concentration of 97%, stir to dissolve it evenly, then slowly add 3 parts of chlorosulfonic acid dropwise, stir and react at 400r / min at 20°C for 1h, and dissolve the reaction After suction filtration, the final product was rinsed with distilled water to neutrality, and then dried at 100°C for 1 hour to obtain sulfonated polyethersulfone;

[0075] 2) Polydopamine modified polyethersulfone

[0076] Take 8 parts of dopamine, add it to tris-hydrochloric acid buffer solution, stir and dissolve to prepare a 3.0 mg / ml dopamine solution, then add the coated wig fiber into it, react at room temperature for 25 hours, take out Finally, wash with ethanol and distilled water alternately for 5 times, and dry at 60°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com