Electrolytic cell with large contact specific surface area for valuable metal recovery

A valuable metal, specific surface area technology, applied in the electrolysis process, electrolysis components, electrodes and other directions, can solve the problems of non-reusable electrodes, reduced electrolysis efficiency, reduced electrolysis efficiency, etc., to increase the recovery rate of valuable metals, improve Effects of stability and high electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

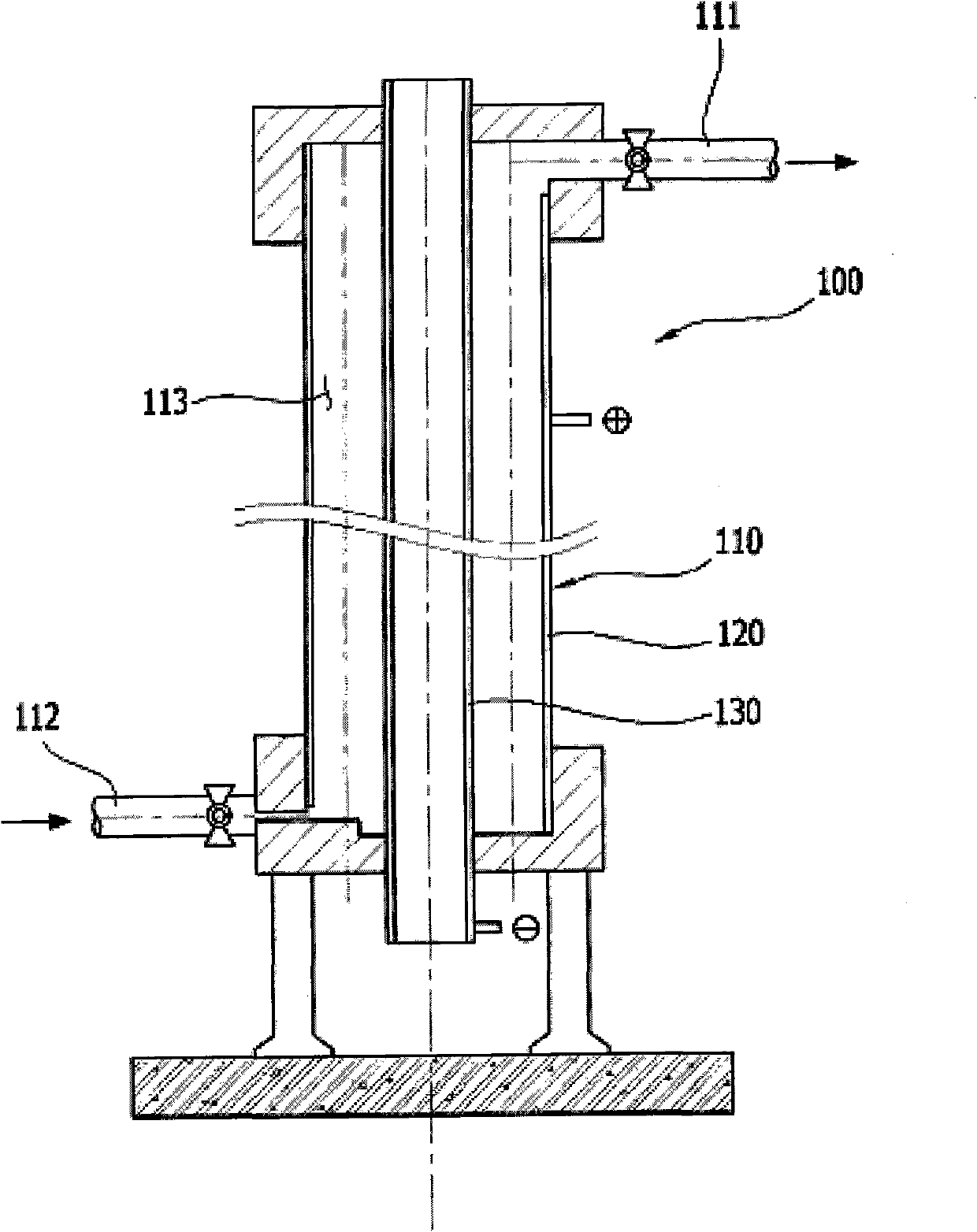

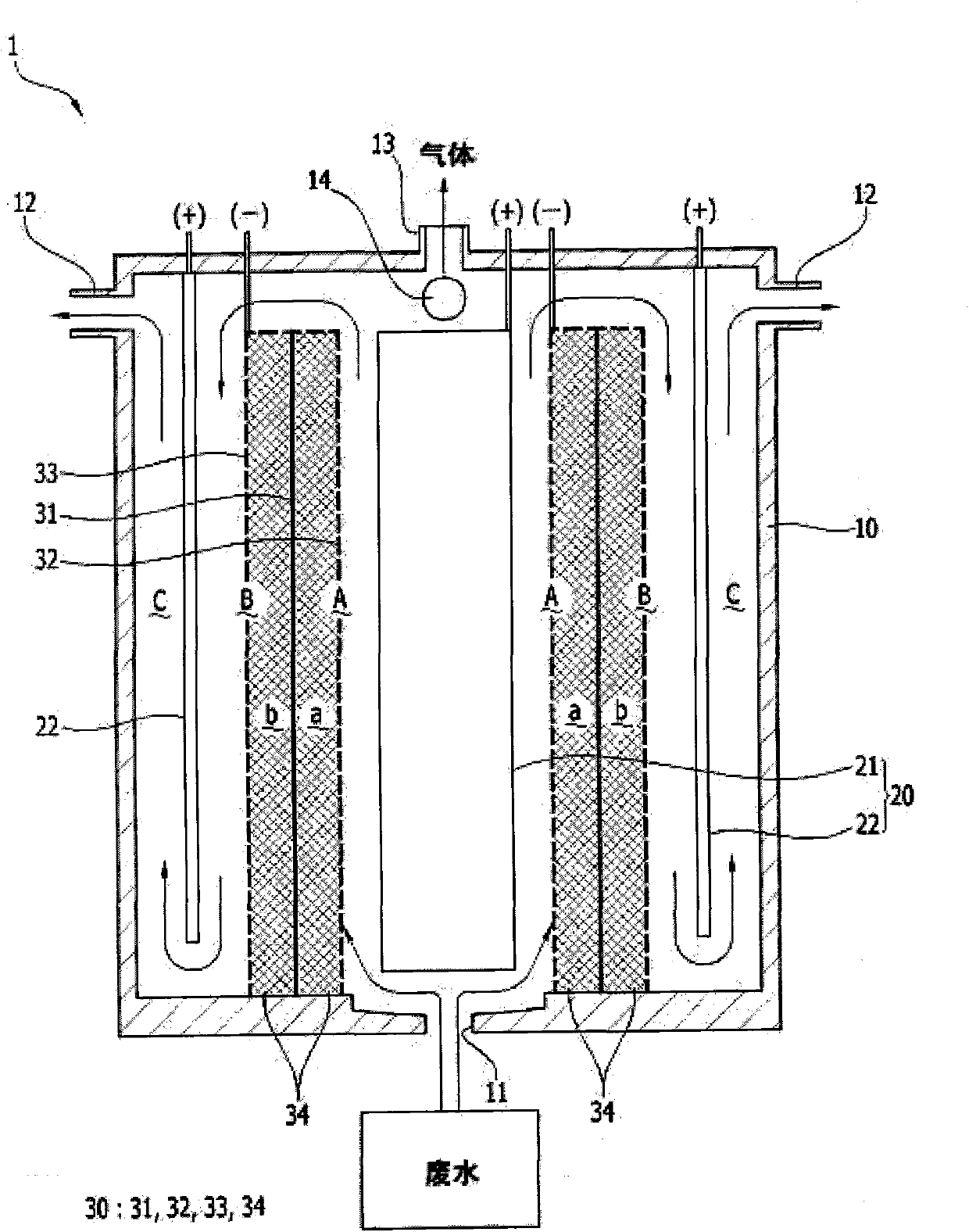

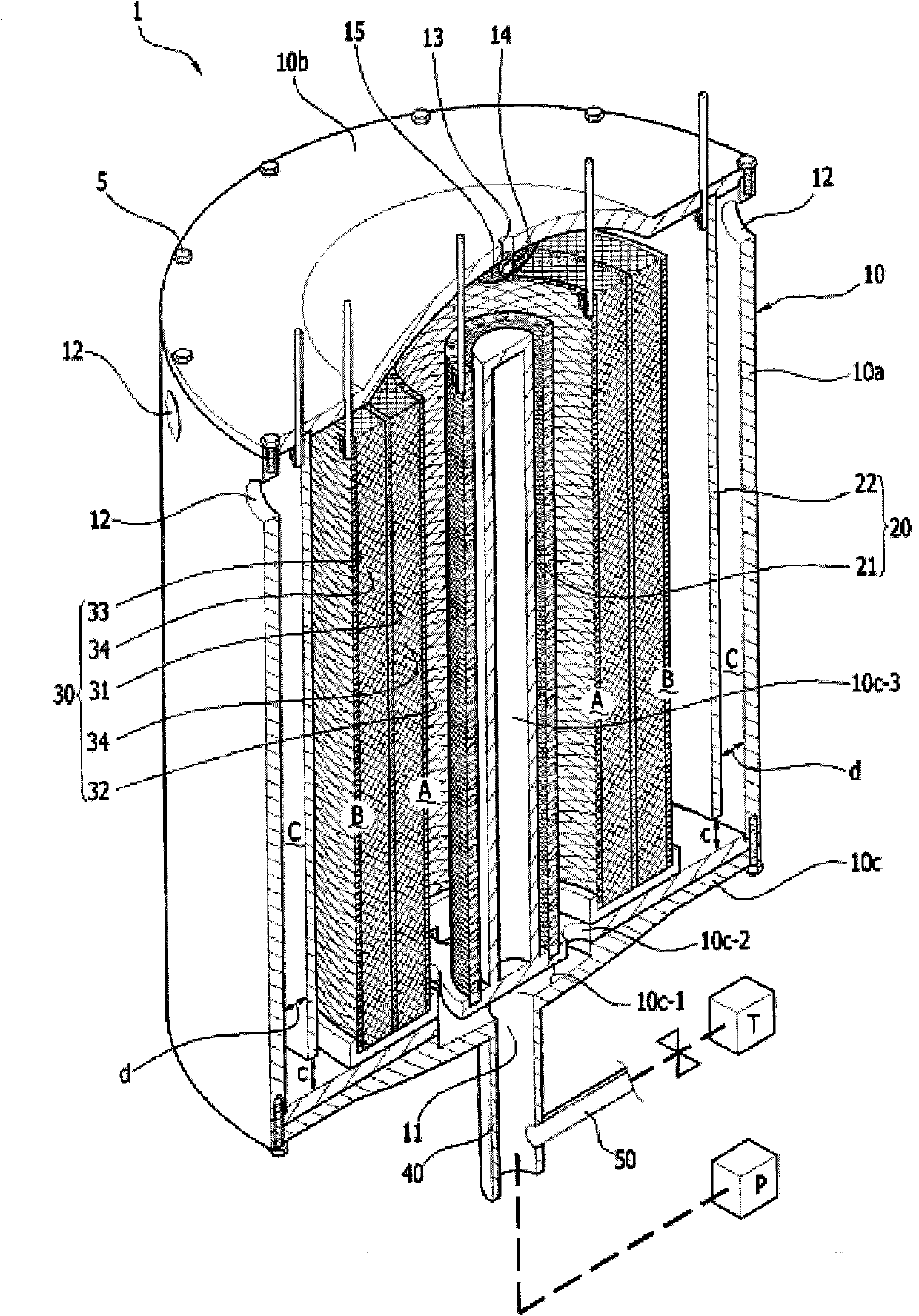

[0063] Hereinafter, a preferred embodiment of the electrolytic cell for valuable metal recovery with increased contact specific surface area of the present invention will be described in detail with reference to the accompanying drawings.

[0064] figure 2 It is a schematic diagram of the structure of the electrolytic cell for valuable metal recovery with increased contact specific surface area of the present invention.

[0065] As shown in the figure, the electrolytic cell 1 for recovering valuable metals with increased contact specific surface area of the present invention has the following structural features, in order to efficiently recover the valuable metals by electrodeposition in gold-plating wastewater or wastewater containing valuable metals The metal can maximize the specific surface area of the electrode in contact with the wastewater flowing into the electrolytic cell 1, thereby improving the electrolysis efficiency; and expanding the electrolysis space, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com