Waste gas treatment process and device adopting reverse flow counter-impact turbulence washing tower

A waste gas treatment device and waste gas treatment technology, applied in the direction of gas treatment, use of liquid separation agent, membrane technology, etc., can solve the problems of easy blockage of fillers and nozzles, complicated process flow, low desulfurization efficiency, etc., and achieve simple structure and high efficiency desulfurization Exhaust gas removal and removal efficiency are high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

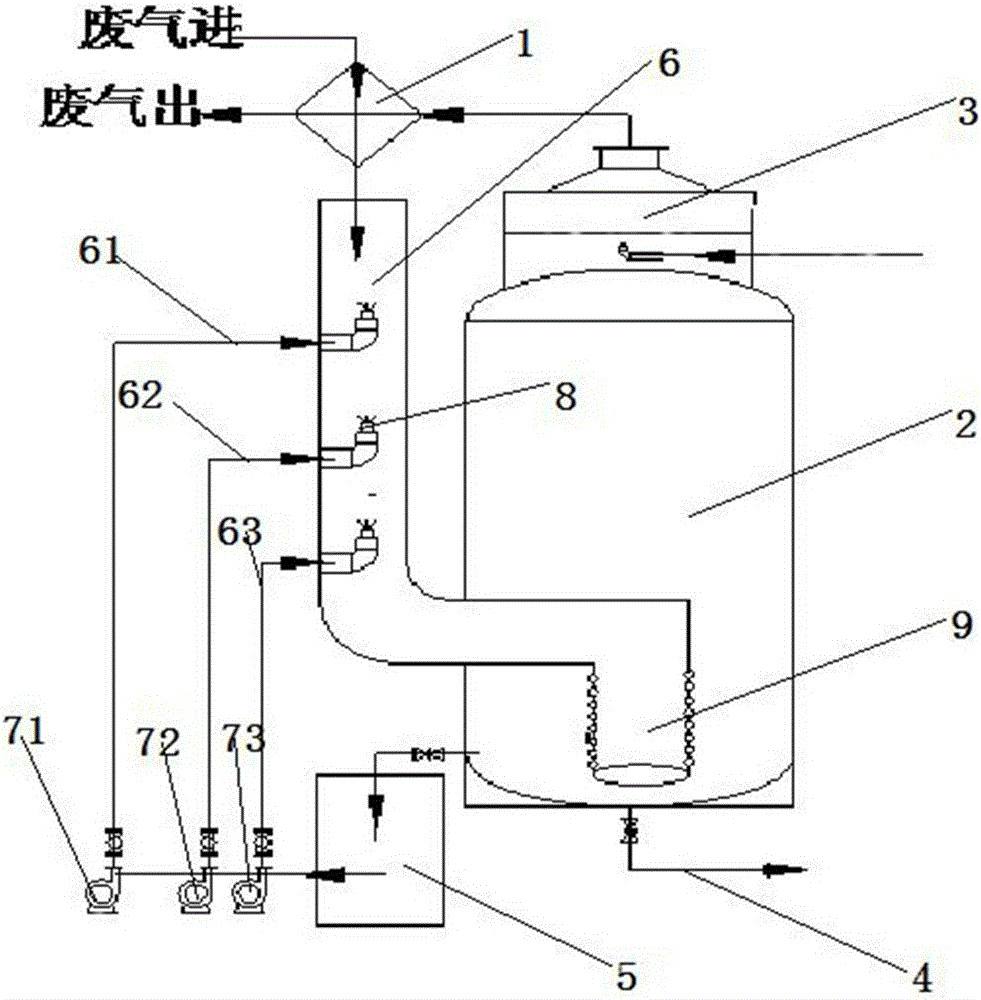

[0039] like figure 1 The device for treating exhaust gas using a countercurrent flushing turbulent scrubber includes a heat exchanger 1, a countercurrent scrubber 2, a demister 3, a saturated liquid discharge pipe 4, an absorption liquid circulation tank 5, and a circulation pump. The countercurrent scrubber is provided with a reverse spray scrubber 6, one end of the reverse spray scrubber is connected to the heat exchanger, and the other end goes deep into the bottom of the countercurrent scrubber, the reverse spray scrubber is provided with a reverse spray structure, and the reverse spray structure passes through The circulating pump is connected to the pipeline of the absorption liquid circulation tank, the demister is arranged on the top of the countercurrent scrubber, the demister is connected to the heat exchanger through a pipeline, and the saturated liquid outlet pipe is arranged at the bottom of the countercurrent scrubber, The countercurrent washing tower is connecte...

Embodiment 2

[0042] A kind of waste gas treatment process using a countercurrent countercurrent turbulent scrubber waste gas treatment device as described in Example 1 includes the following steps:

[0043] (1) The exhaust gas passes through the heat exchanger and enters the reverse spray washing pipe of the countercurrent scrubber, and contacts with the upward spraying primary reverse spray, secondary reverse spray or tertiary reverse spray absorption liquid circulation system to obtain a mixed absorption liquid, forming Gas-liquid turbulent foam washing zone;

[0044] (2) The mixed absorption liquid enters the bottom of the countercurrent washing tower along the flow, and enters the perforated pipe to form a gas-liquid or liquid-liquid bubbling washing area.

[0045] (3) The exhaust gas after passing through the bubbling washing area passes through the demister, and then through the outlet of the heat exchanger to discharge the purified exhaust gas.

[0046] When exhaust SO 2 The conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com