Method for preparing multi-stage SnO2 nanotubular gas sensitive material and application of method

A gas-sensitive material and nanotechnology, applied in the direction of tin oxide, etc., can solve the problems of human health and surrounding environment, harsh reaction conditions, cumbersome steps, etc., and achieve good application prospects, low water and heat temperature, and auxiliary performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

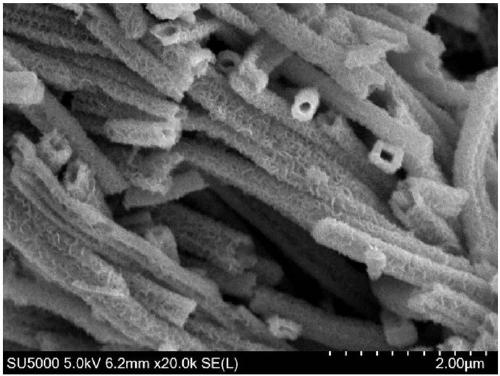

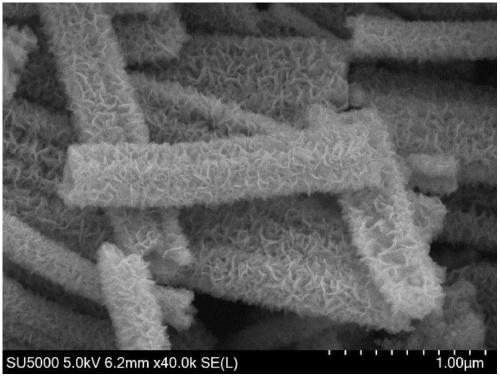

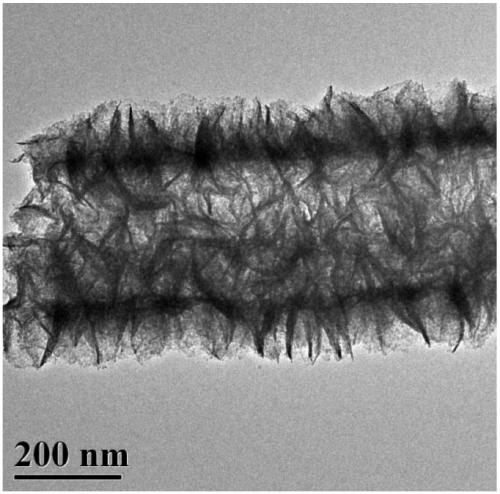

[0034] A multilevel SnO 2 A method for preparing a nanotube-shaped gas-sensitive material, comprising the following steps:

[0035] (1) Add 0.45g of PVP (MW.58000) into 25ml of ethylene glycol, stir for 30min, and sonicate for 10min until the solution is clear to obtain a solution;

[0036] (2) Add 15 mg of molybdenum oxide nanorods into solution a, stir for 1 h until molybdenum oxide is evenly dispersed in solution a, and obtain solution b;

[0037] (3) Add 1.6ml tin protochloride solution (0.758g tin protochloride dissolved in 10ml ethylene glycol) and 1.6ml thioacetamide solution (0.3g thioacetamide dissolved in 10ml ethylene glycol) to b solution, stirred for 20 minutes, then transferred to a 50ml polytetrafluoroethylene-lined stainless steel reaction kettle, heated at a constant temperature of 160°C for 12 hours;

[0038] (4) collect after cooling, collect by centrifugation with dehydrated alcohol, repeat 5 times, then transfer the gained precipitation in the beaker wit...

Embodiment 2

[0041] (1) Add 0.5g of PVP (MW.58000) into 25ml of ethylene glycol, stir for 30min, and sonicate for 10min until the solution is clear;

[0042] (2) Add 20 mg of molybdenum oxide nanorods into the solution a, and stir for 1 h until the molybdenum oxide is evenly dispersed in the solution a;

[0043] (3) Add 1.6ml tin protochloride solution (0.758g tin protochloride dissolved in 10ml ethylene glycol) and 1.6ml thioacetamide solution (0.3g thioacetamide dissolved in 10ml ethylene glycol) to b solution, stirred for 20 minutes, then transferred to a 50ml polytetrafluoroethylene-lined stainless steel reaction kettle, and heated in constant temperature water for 12 hours;

[0044] (4) collect after cooling, collect by centrifugation with dehydrated alcohol, repeat 5 times, then transfer the gained precipitation in the beaker with 20ml dehydrated alcohol, add 3ml concentrated ammonia water, stir 90min, its purpose is to remove molybdenum oxide template, Then it was collected by cent...

Embodiment 3

[0047] A multilevel SnO 2 A method for preparing a nanotube-shaped gas-sensitive material, comprising the following steps:

[0048] (1) Add 0.45g of PVP (MW.58000) into 45ml of ethylene glycol, stir for 30min, and sonicate for 10min until the solution is clear to obtain a solution;

[0049] (2) Add 24 mg of molybdenum oxide nanorods into solution a, stir for 1 h until the molybdenum oxide is evenly dispersed in solution a, and obtain solution b;

[0050] (3) Add 2.18ml tin protochloride solution (0.5g tin protochloride dissolved in 10ml ethylene glycol) and 2.62ml thioacetamide solution (0.5g thioacetamide dissolved in 10ml ethylene glycol) to b solution, stirred for 20 minutes, then transferred to a 50ml polytetrafluoroethylene-lined stainless steel reaction kettle, heated at a constant temperature of 150°C for 14 hours;

[0051] (4) collect after cooling, collect by centrifugation with dehydrated alcohol, repeat 3 times, then transfer the gained precipitation in the beaker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com