Efficient combined preprocessing method for straws

A pretreatment and straw technology, applied in the direction of fermentation, etc., can solve the problems of hindering the enzymatic hydrolysis of cellulose, inability to remove lignin, unfavorable enzymatic hydrolysis efficiency, etc., to promote enzymatic hydrolysis, shorten ball milling time, and improve enzymatic hydrolysis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

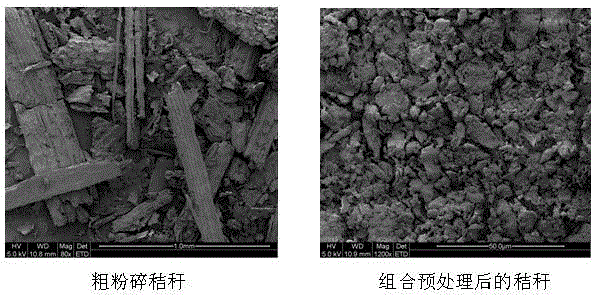

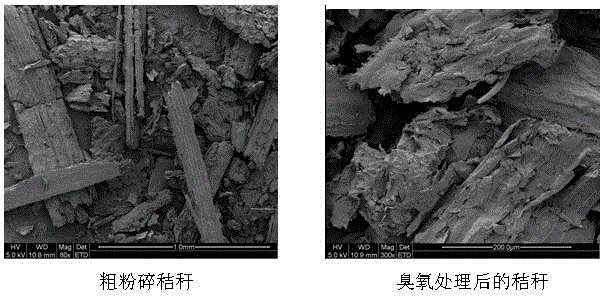

[0033] Example 1: Combination Pretreatment Scheme 1 of Corn Stalk Ozone-Ball Milling

[0034] Coarsely pulverize the corn stalks with a pulverizer, pass the pulverized material through a 30-mesh sieve, and take the sieved material. Add 1 times (v / w) deionized water to the undersieve, mix well, and then pass ozone treatment, the ozone concentration is 60 mg / L, the ozone flow rate is 1.0 L / h, and the ozone treatment time is 2h; the ozone The treated straw was dried naturally, and then added to the ball mill tank, the mass ratio of straw to ball was 1:20, the speed of the ball mill was 1116 rpm, and the ball milled for 24 min.

[0035] Add 20 times (v / w) deionized water to the straw after combined treatment, mix well and let it stand for 0.5 h, then collect the solid by filtration to remove small molecular organic acids and other substances; in the straw after washing and removing acid Add 20 times (v / w) sodium citrate buffer at pH 4.8, pre-added complex cellulase in the buffer,...

Embodiment 2

[0038] Example 2: Combination Pretreatment Scheme 2 of Corn Stalk Ozone-Ball Milling

[0039]Coarsely pulverize the corn stalks with a pulverizer, pass the pulverized material through a 30-mesh sieve, and take the sieved material. Add 0.4 times (v / w) deionized water to the undersieve, mix well, and then pass ozone treatment, the ozone concentration is 20 mg / L, the ozone flow rate is 2.0 L / h, and the ozone treatment time is 0.5 h; The straw after ozone treatment was dried in vacuum, and then added to the ball mill tank, the mass ratio of straw to ball was 1:10, the speed of ball mill was 279 rpm, and the ball mill was milled for 1 min.

[0040] Add 5 times (v / w) deionized water to the straw after combined treatment, mix well and let it stand for 0.5 h, then collect the solid by suction filtration to remove small molecular organic acids and other substances; the straw after washing with water Add 5 times (v / w) sodium citrate buffer solution with pH 4.8 to the buffer, pre-added ...

Embodiment 3

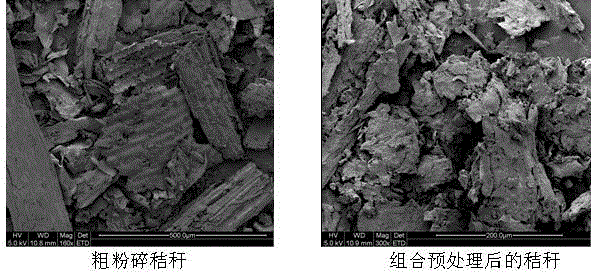

[0043] Example 3: Combination Pretreatment Scheme 1 of Corn Stalk Milling-Ozone

[0044] Coarsely pulverize the corn stalks with a pulverizer, pass the pulverized material through a 30-mesh sieve, and take the undersieve; put the undersieve into the ball mill tank, the mass ratio of the straw to the ball is 1:20, the speed of the ball mill is 558 rpm, and the ball mill 2 min; take the ball-milled straw, add 1 times (v / w) deionized water, mix well, and then pass ozone treatment, the ozone concentration is 80 mg / L, the ozone flow rate is 0.5 L / h, the ozone treatment time for 1.5 h.

[0045] Add 15 times (v / w) deionized water to the straw after combined treatment, mix well and let it stand for 1 hour, then collect the solid by centrifugation to remove small molecular organic acids and other substances; in the straw after washing and removing acid Add 15 times (v / w) sodium citrate buffer solution with pH 4.8, pre-added compound cellulase in buffer, compound cellulase contains cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com