Patents

Literature

40results about How to "Increase flame length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

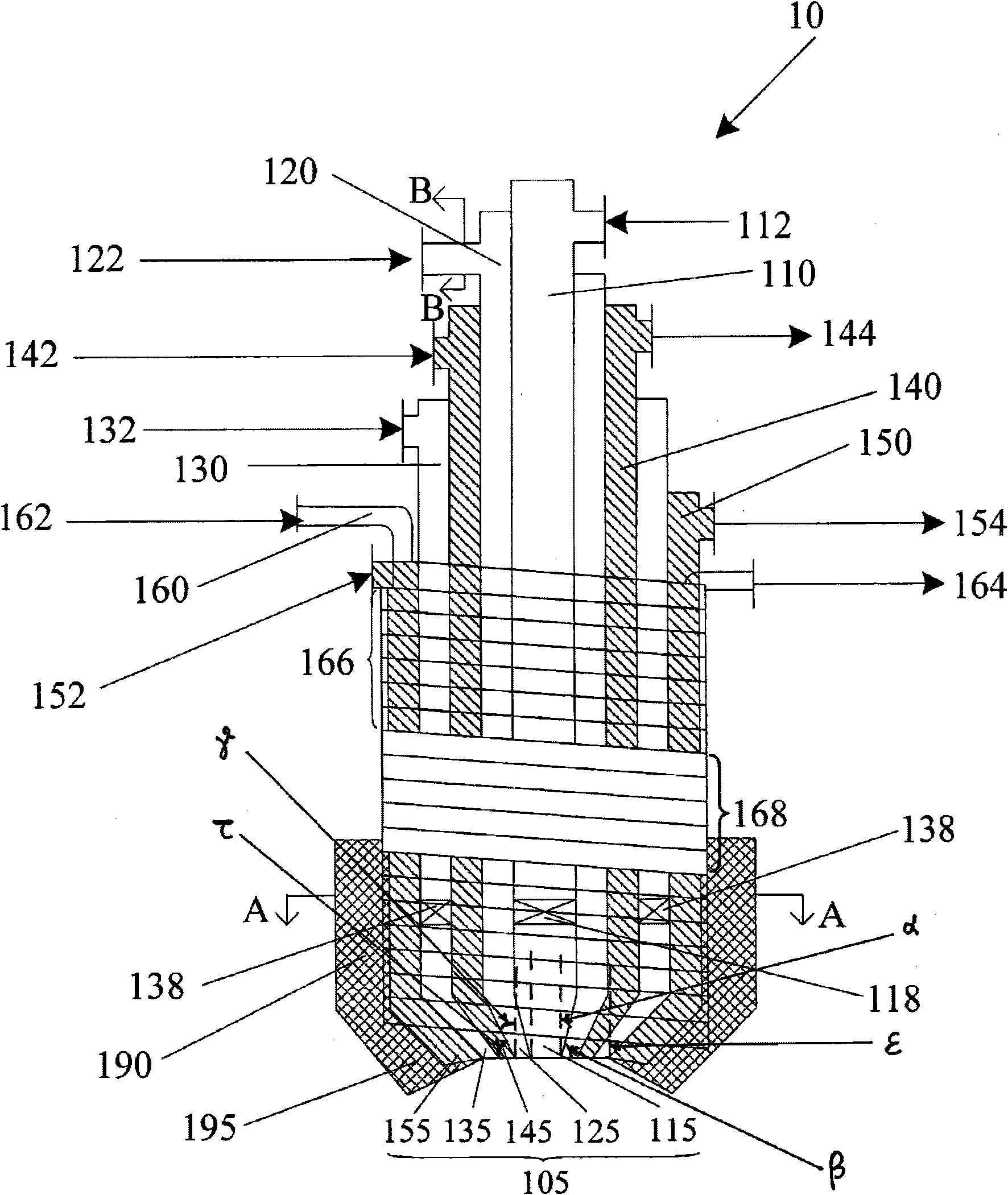

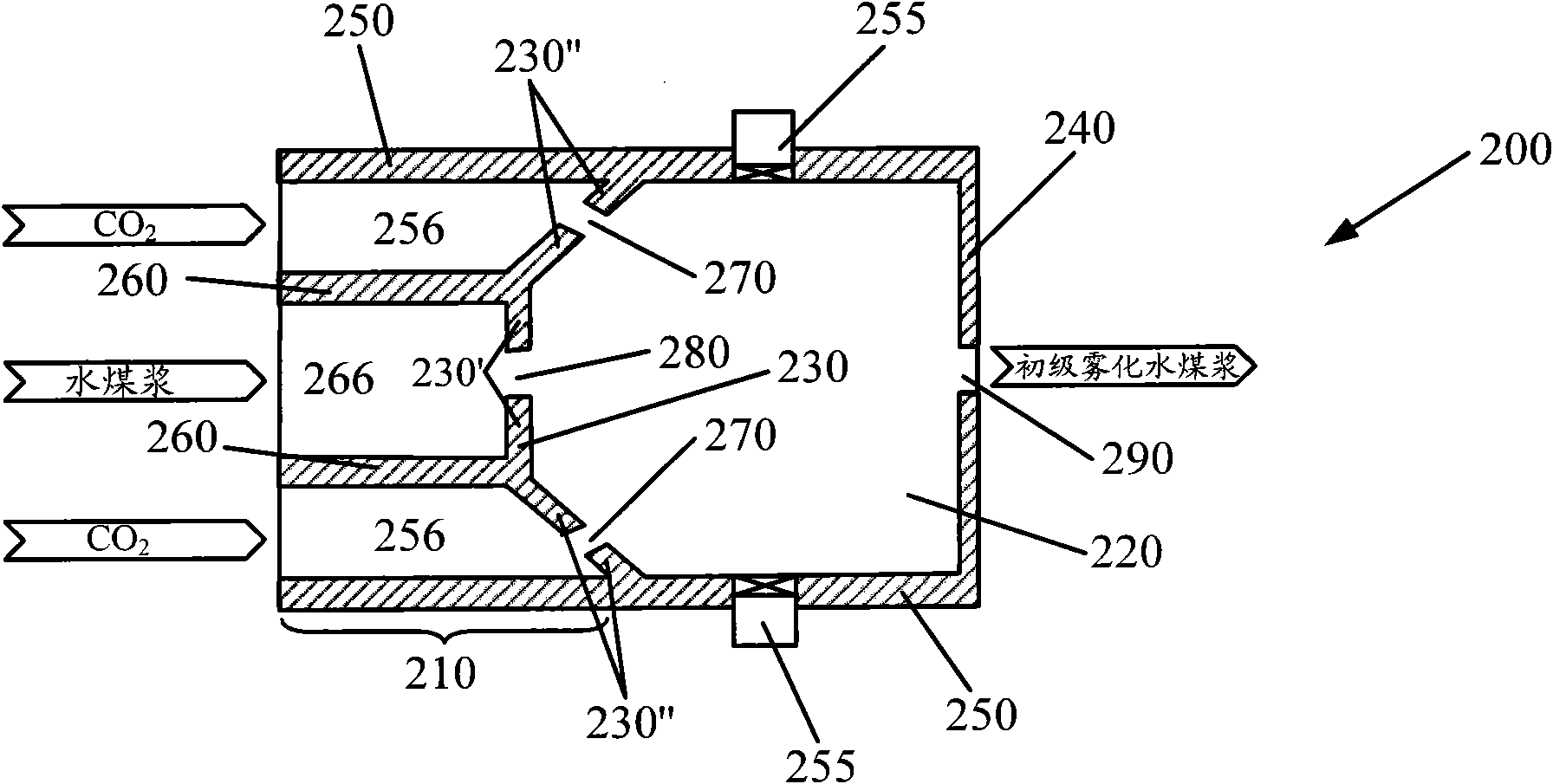

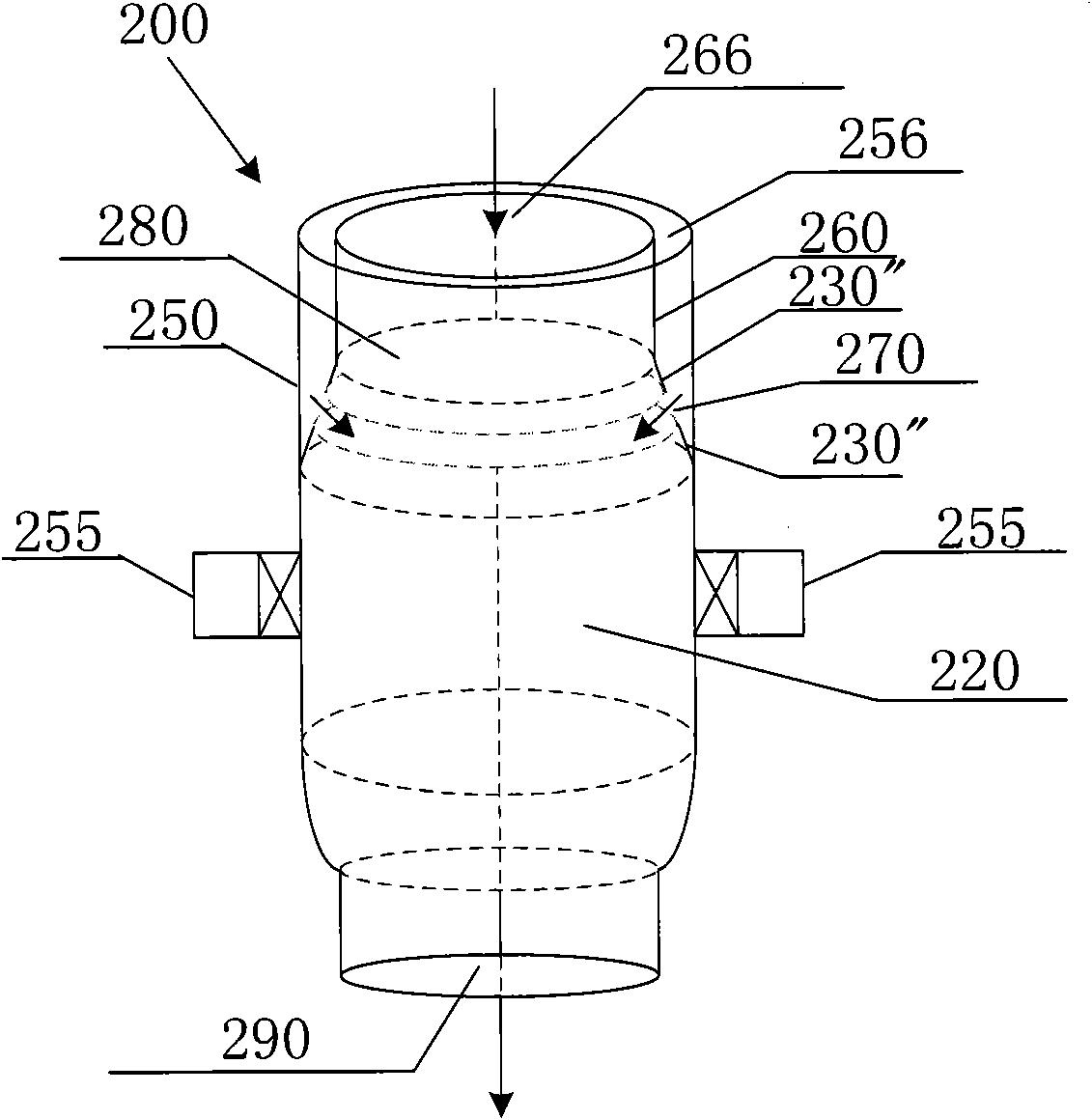

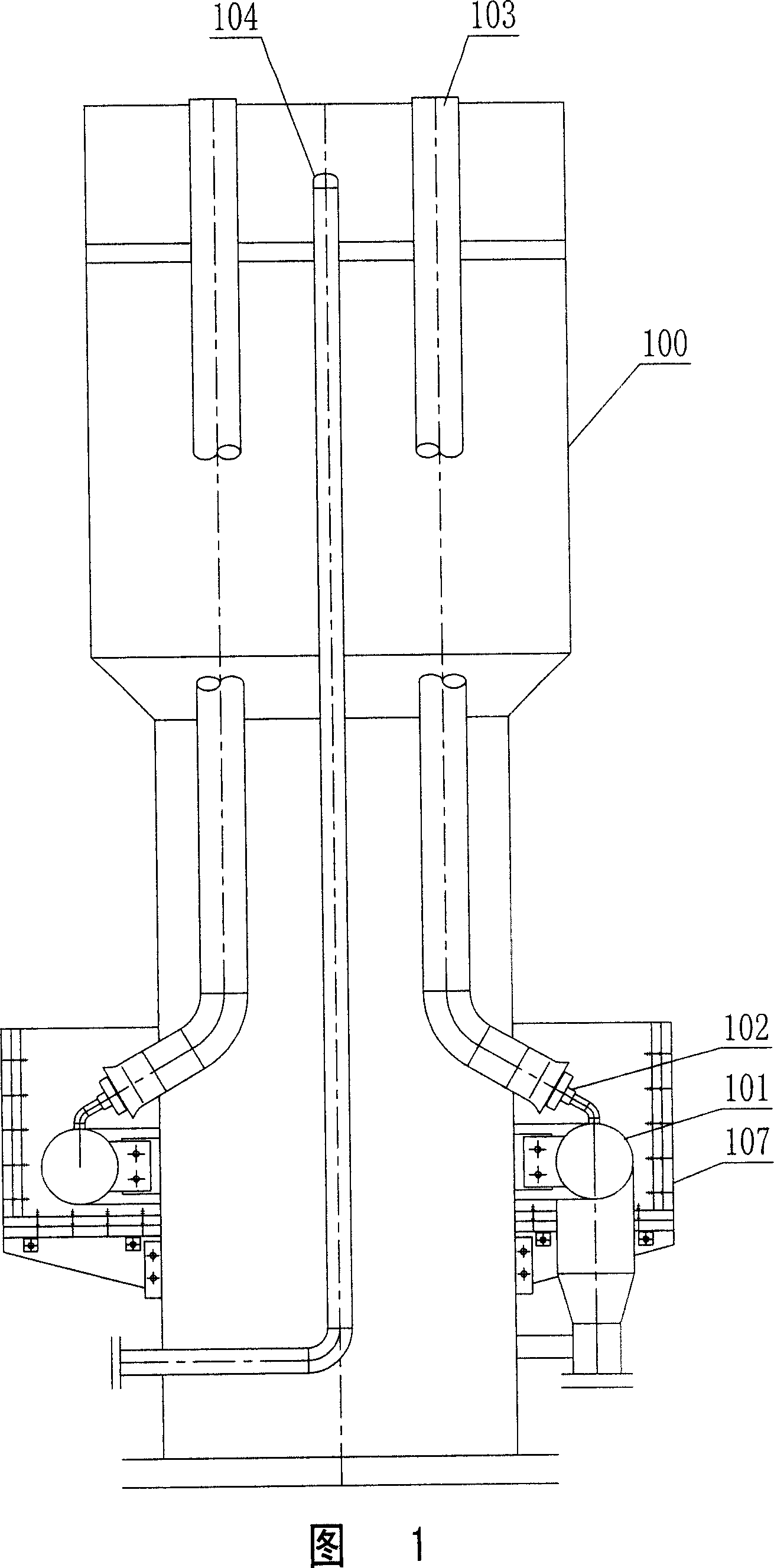

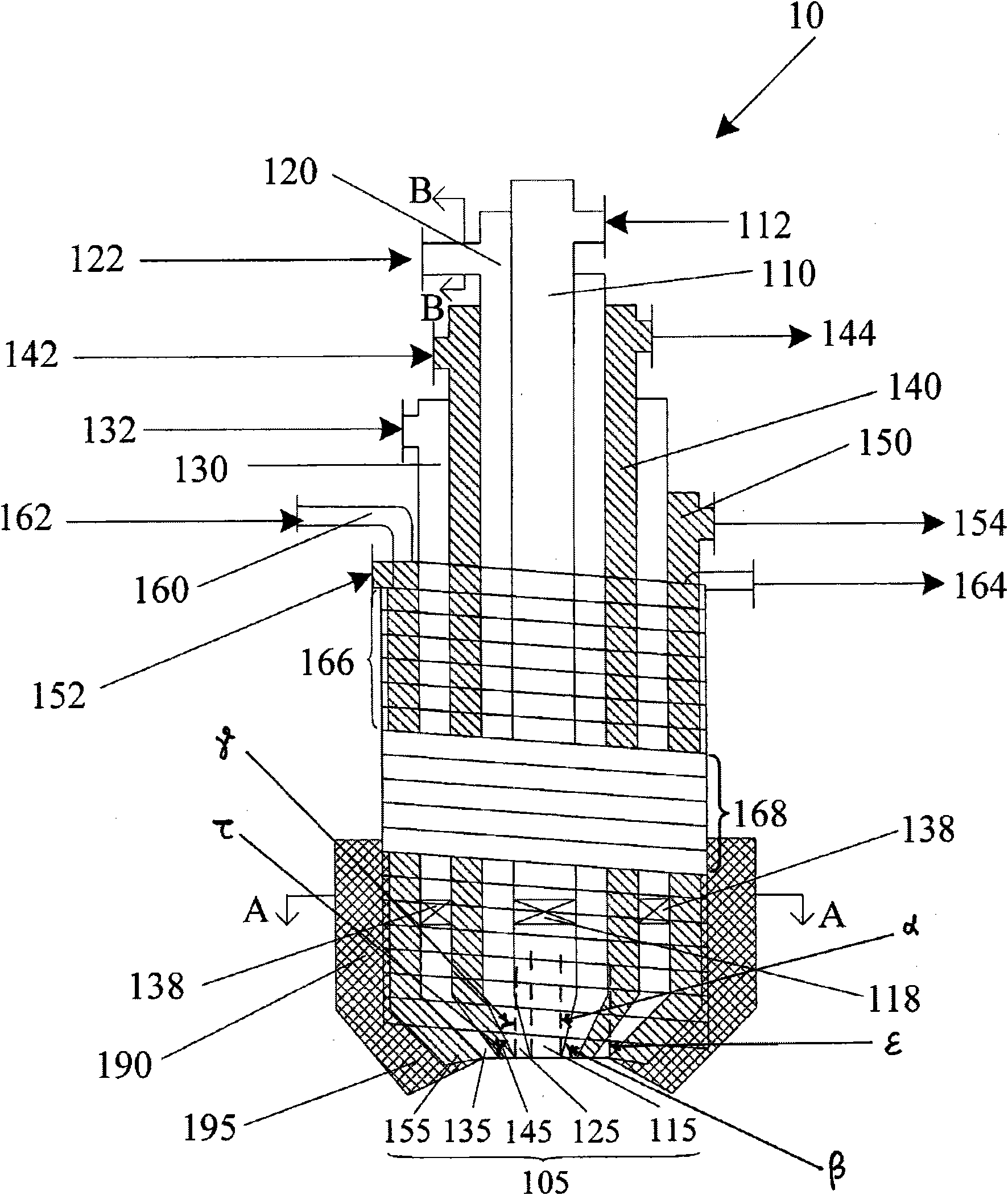

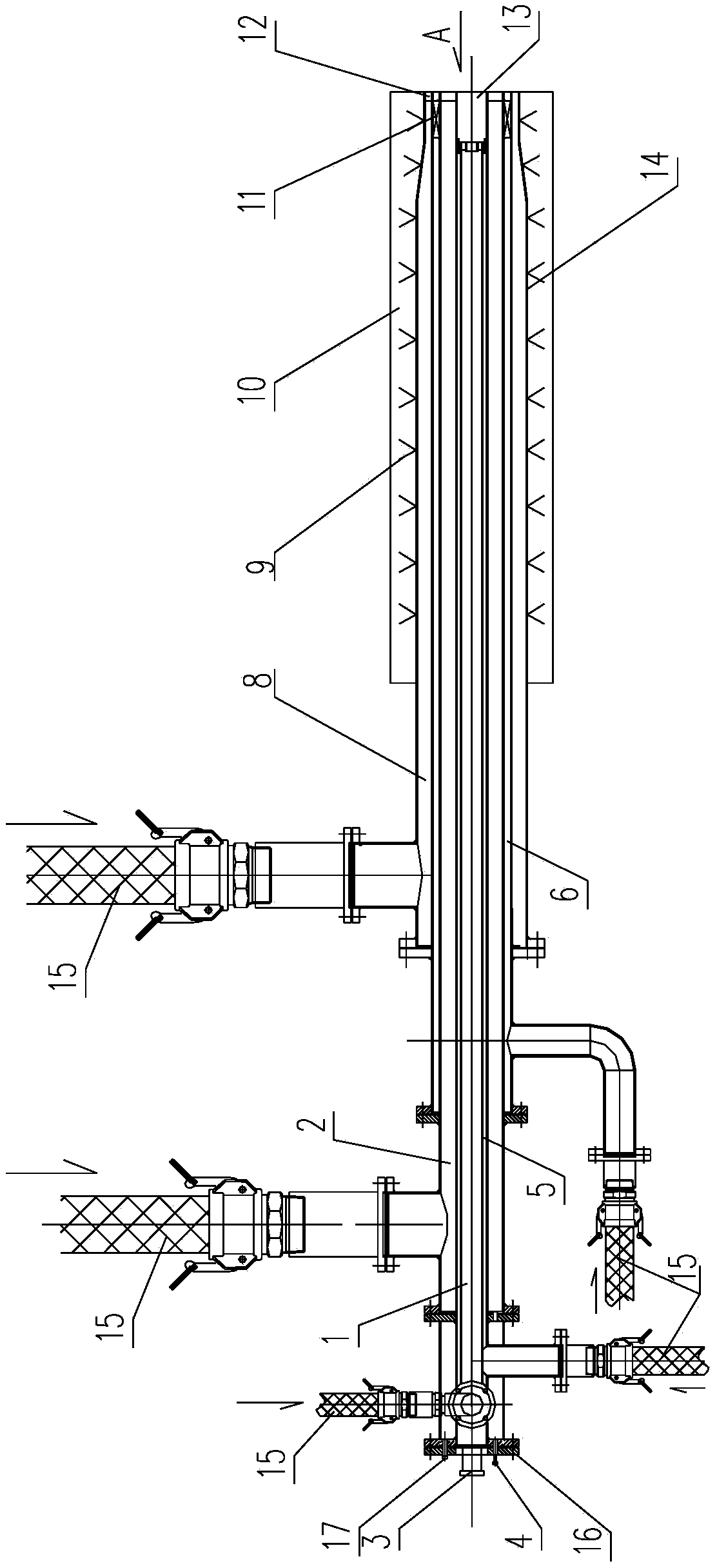

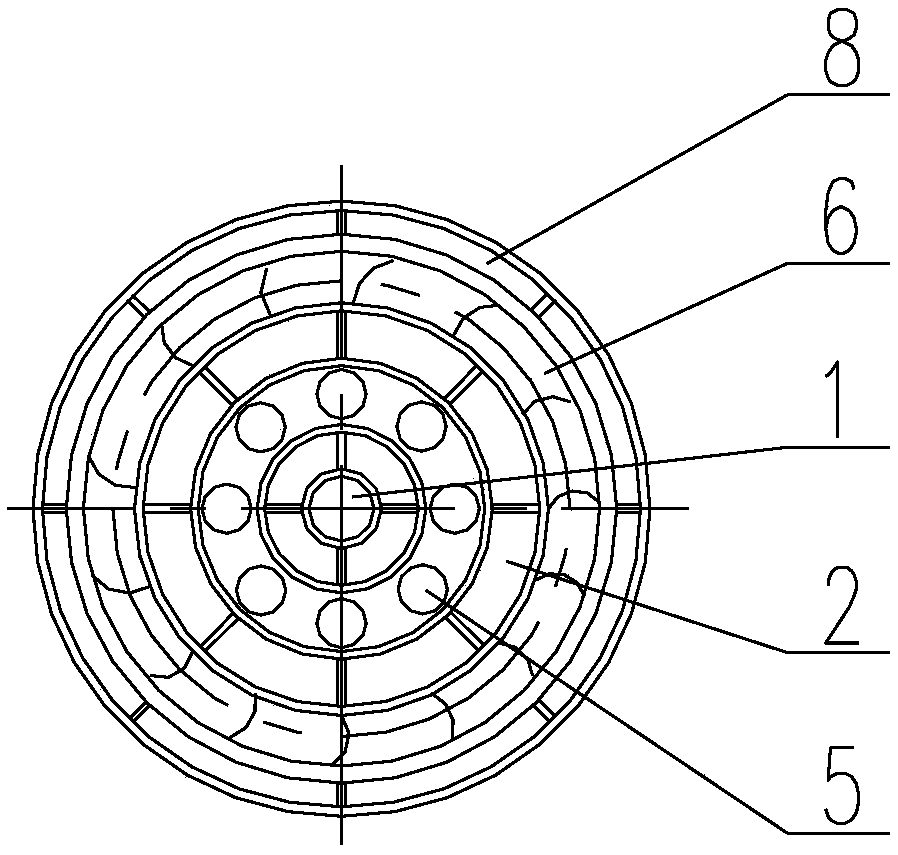

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152AEffective protectionImprove cooling effectLiquid spraying apparatusGranular/pulverulent flues gasificationCoal slurryWater jacket

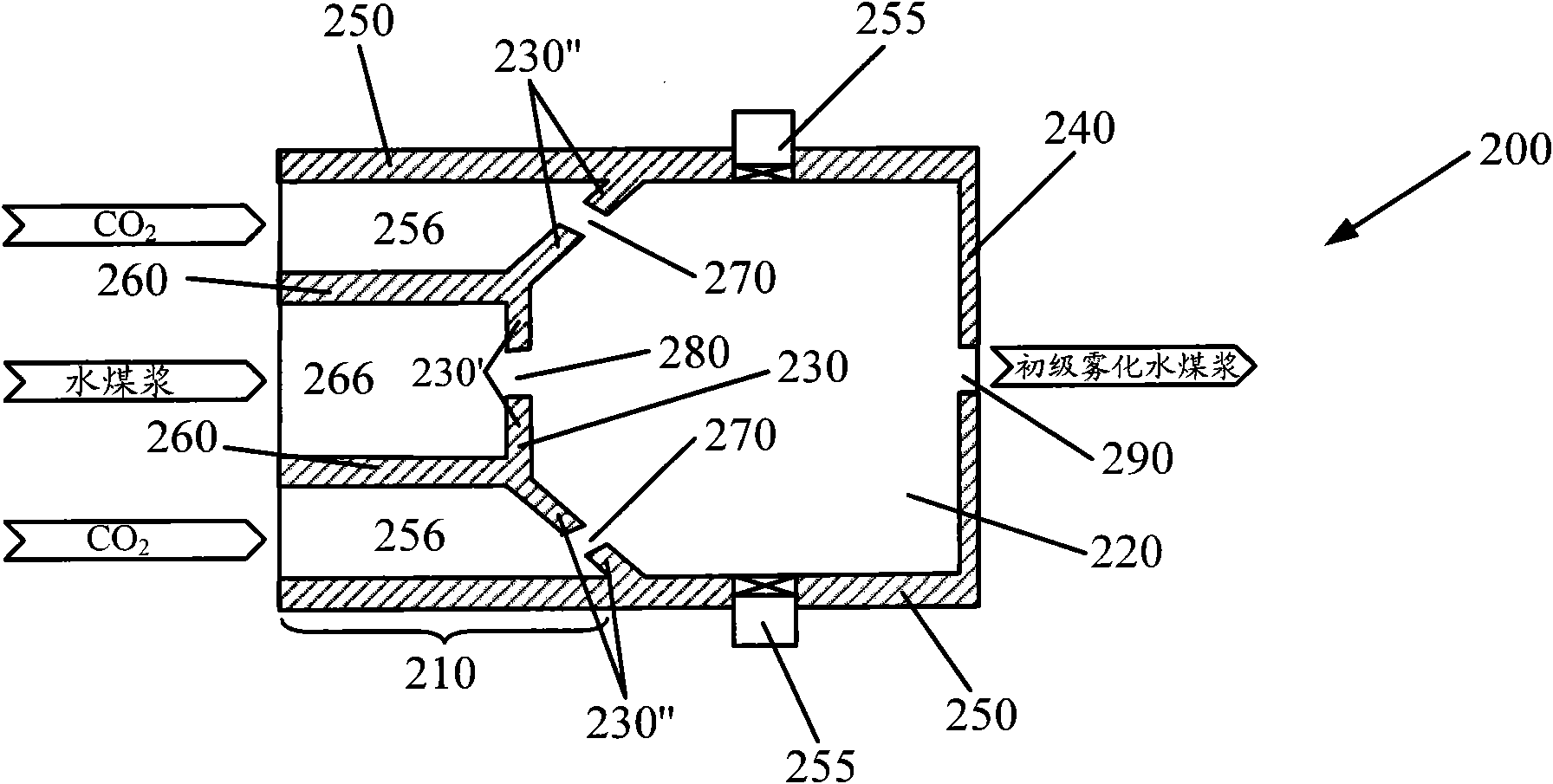

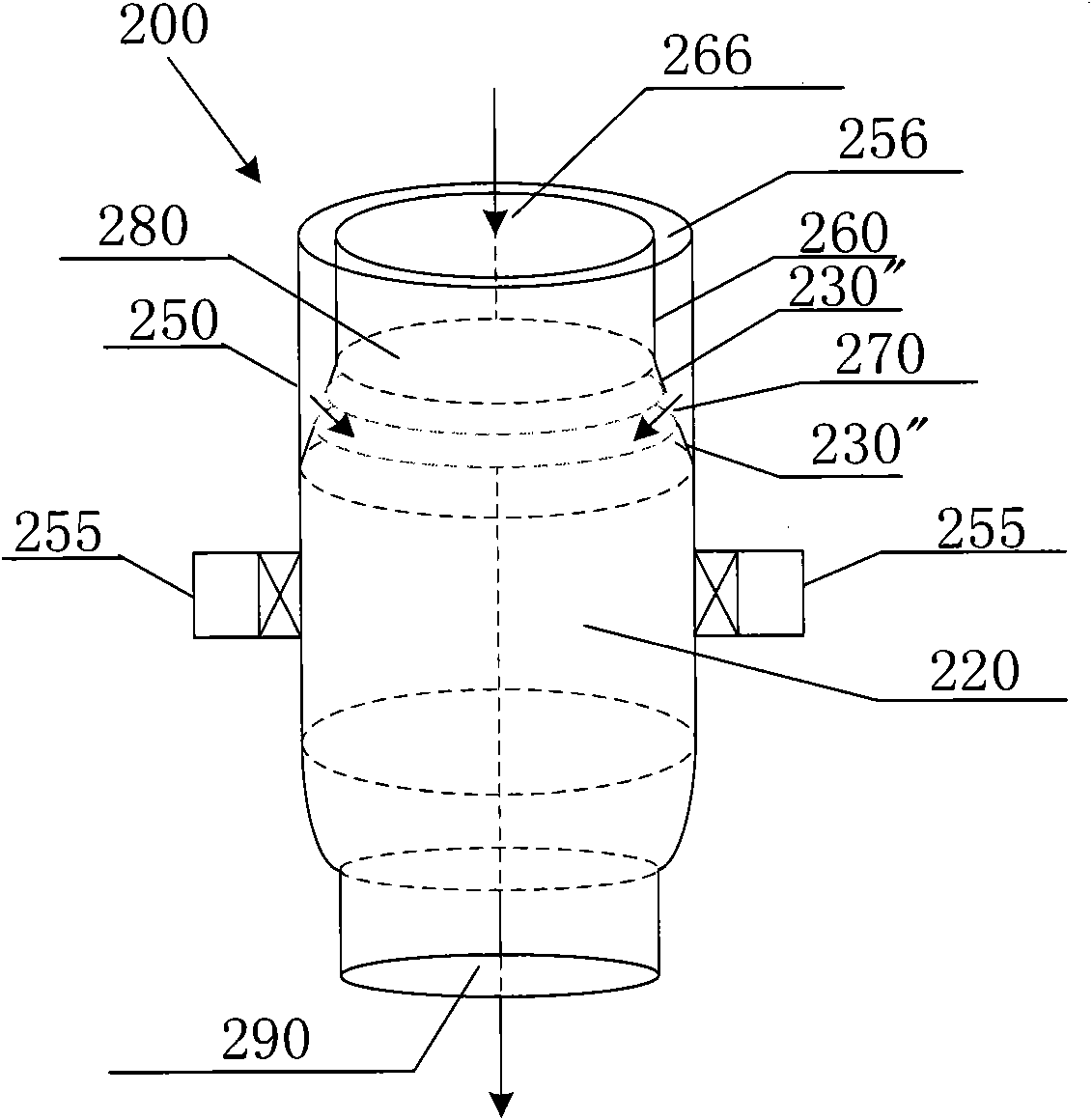

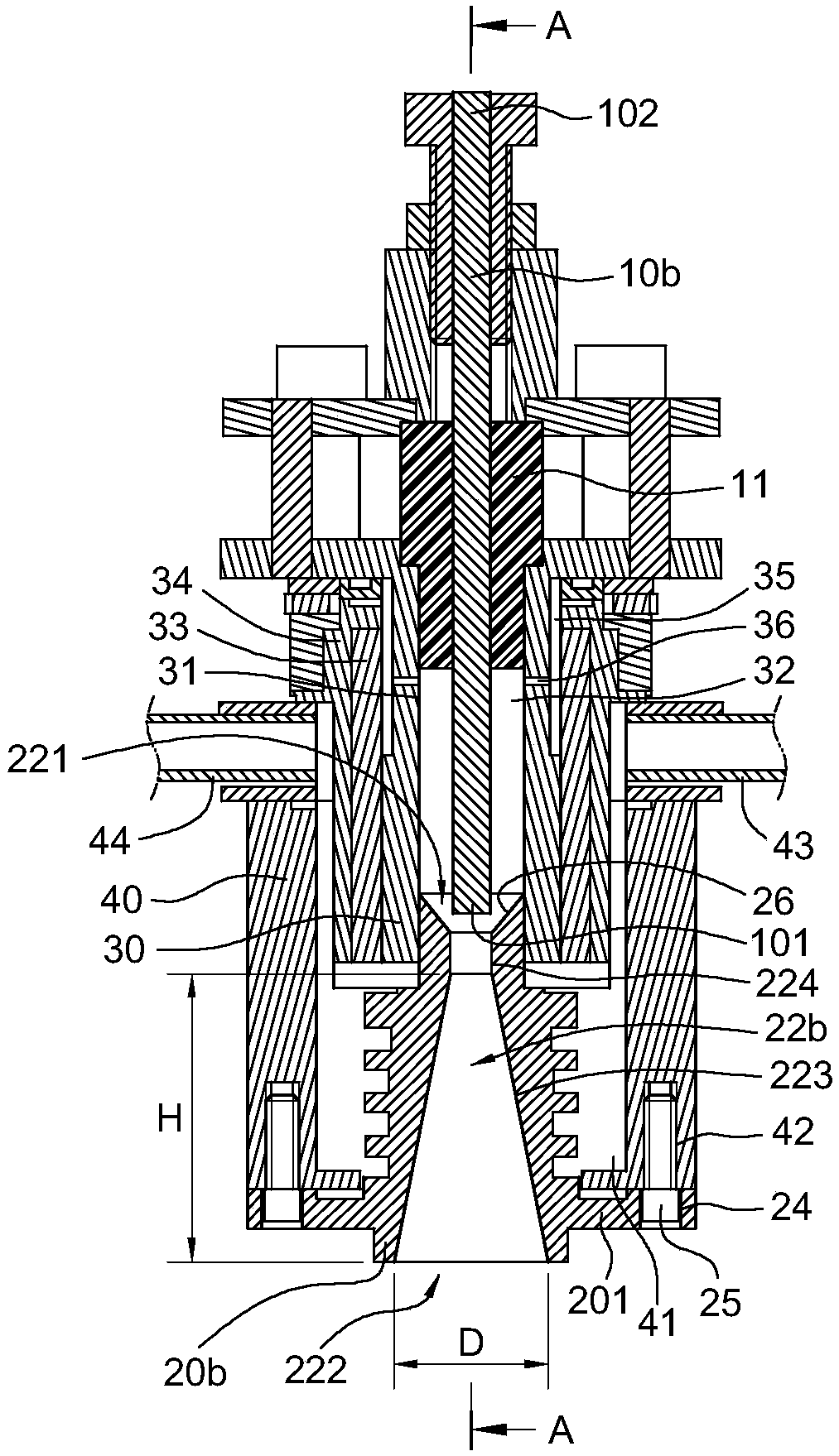

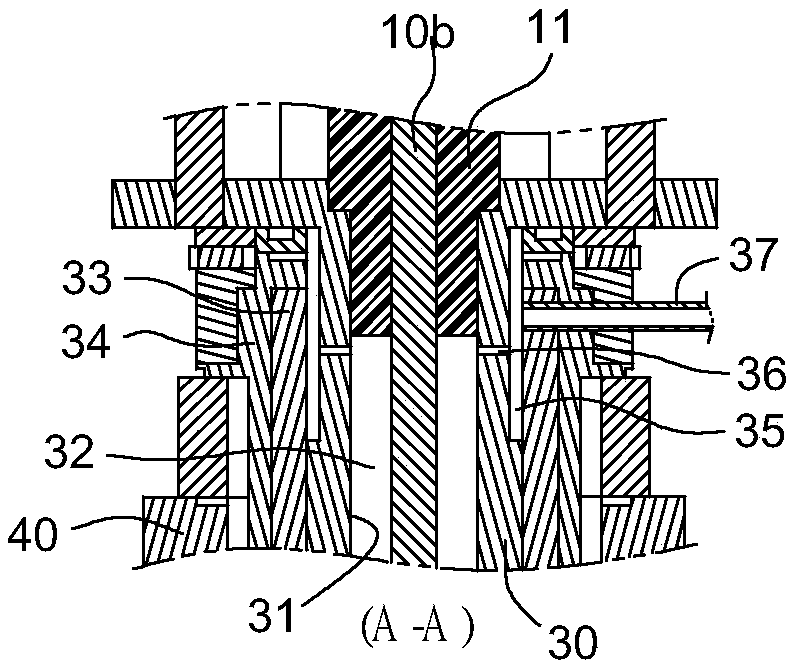

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

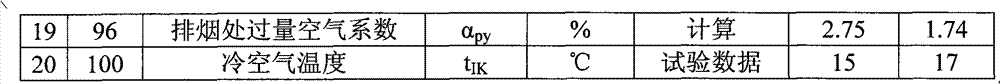

Steam combustion-supporting type torch burner

ActiveCN1959211AHigh smoke suppression effectExtend your lifeIncinerator apparatusGaseous fuel burnerCombustorTorch

A torch burner of steam combustion-assisting type consists of cylinder body, central jet pipe of steam, steam ring pipe, nozzle and jet pipe of steam-air. It is featured as setting nozzle jacketed on steam ring pipe far from top of cylinder body, aligning nozzle to entrance of jet pipe of steam-air and setting steam jet component far from high temperature region at top of burner.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

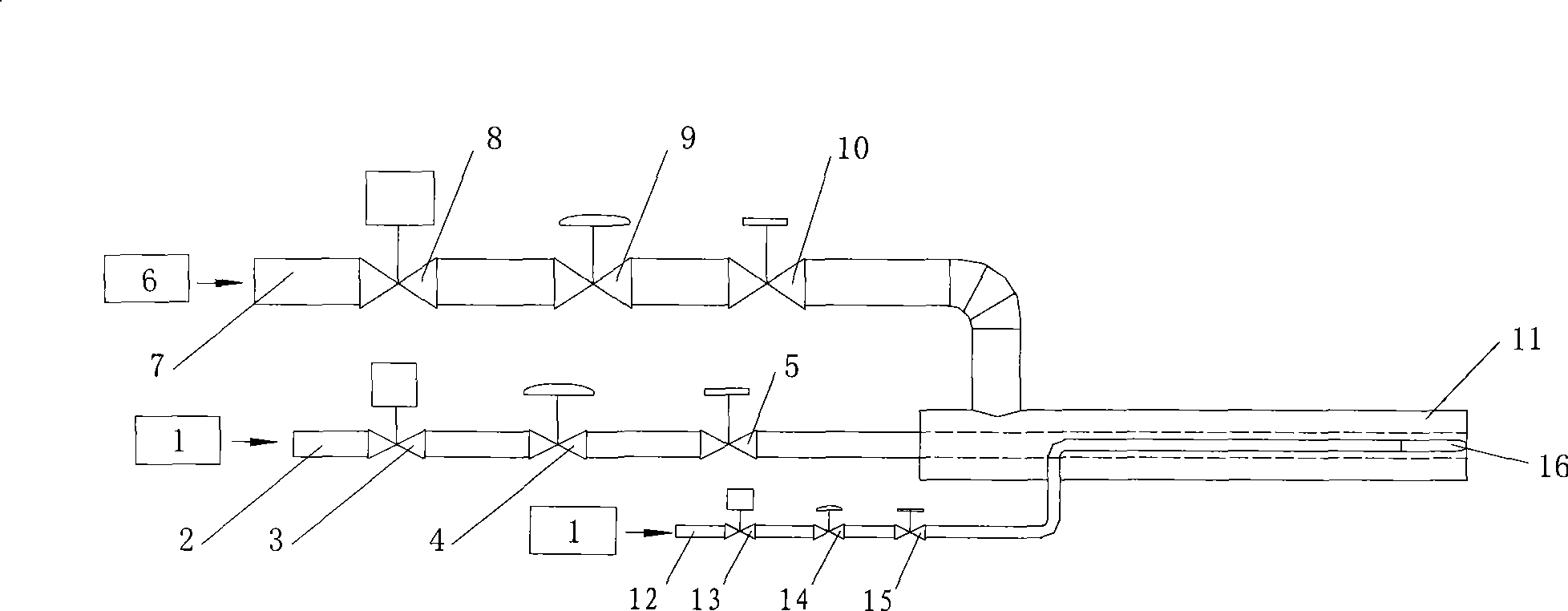

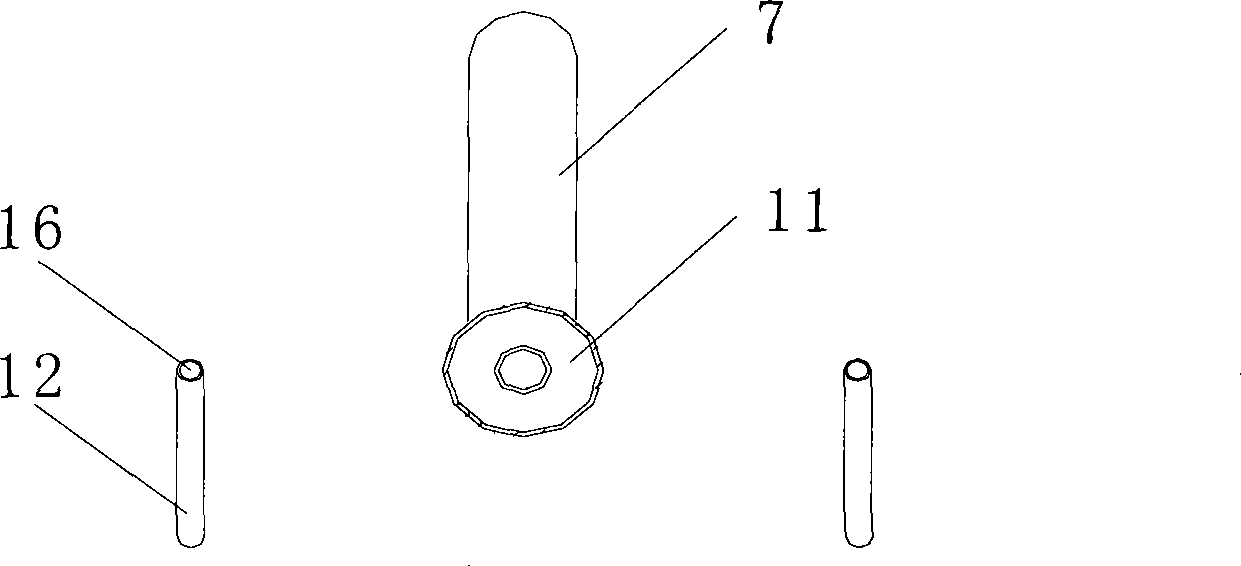

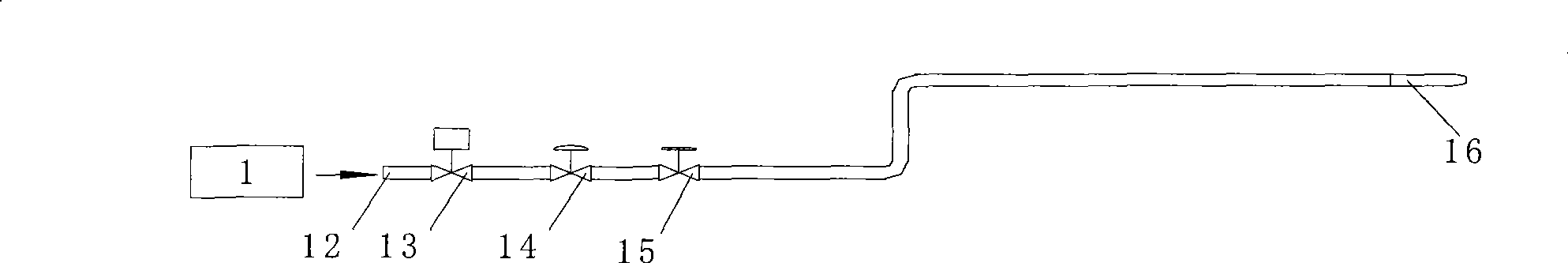

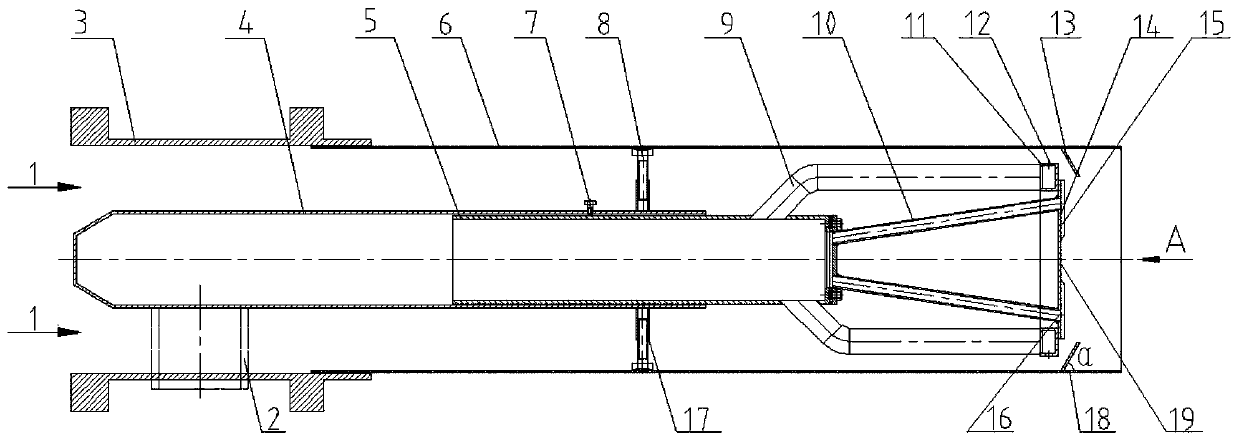

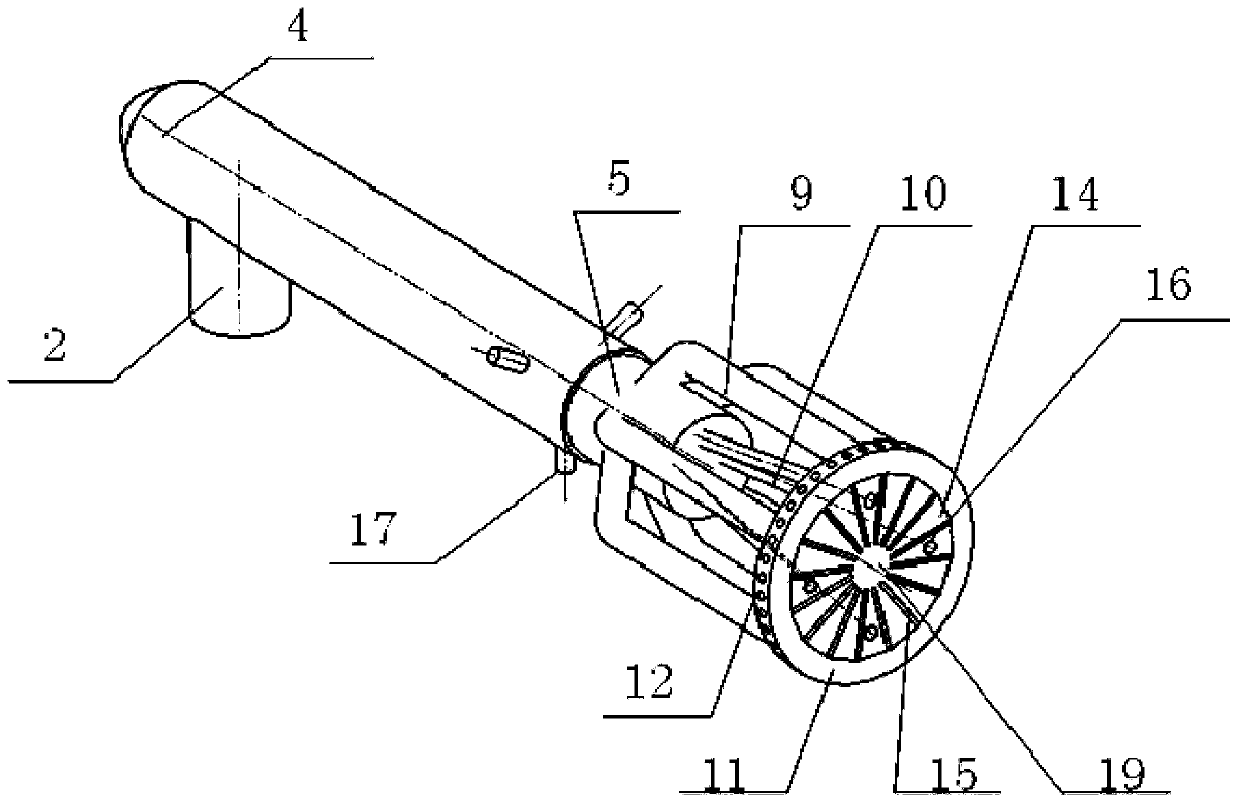

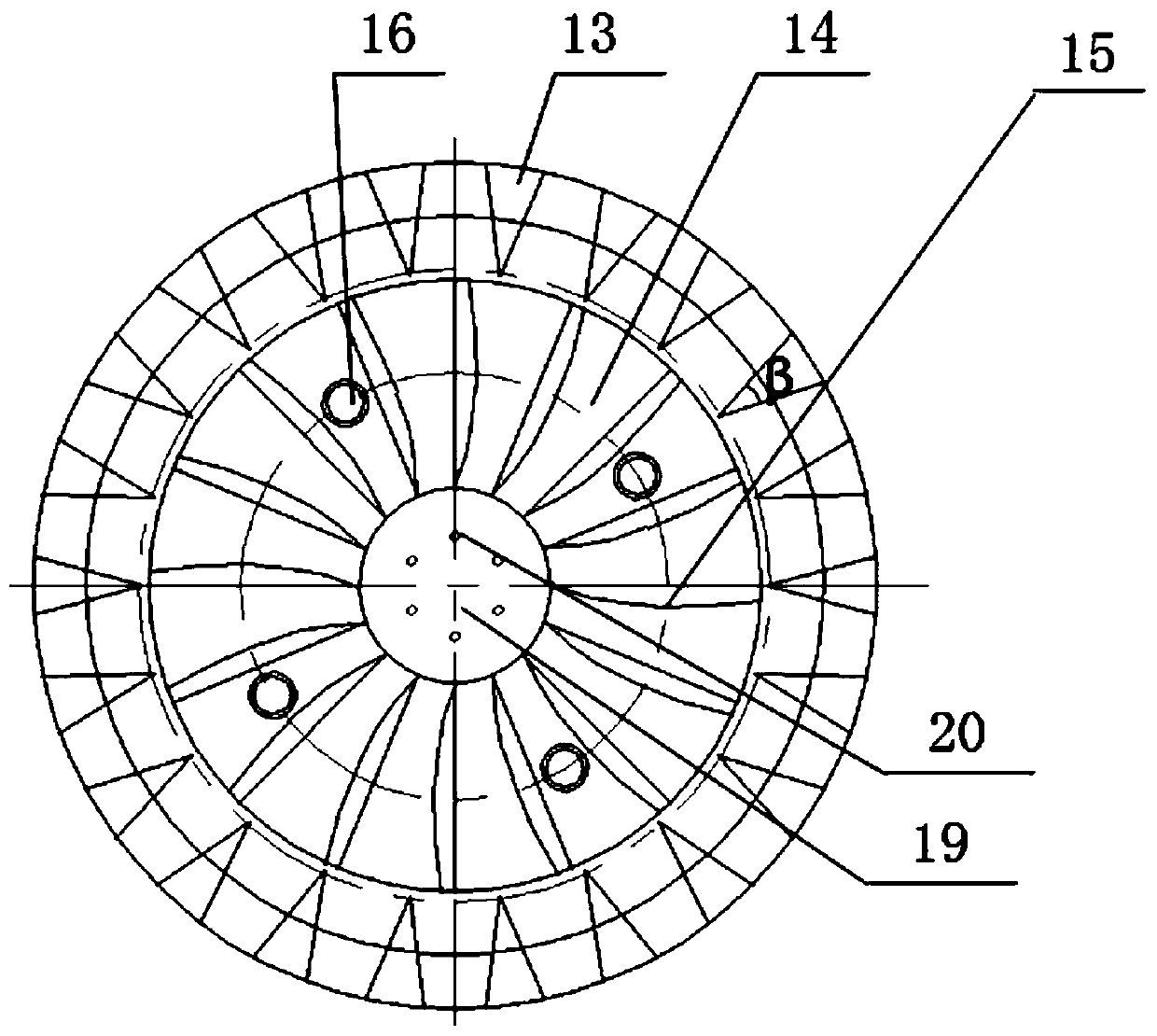

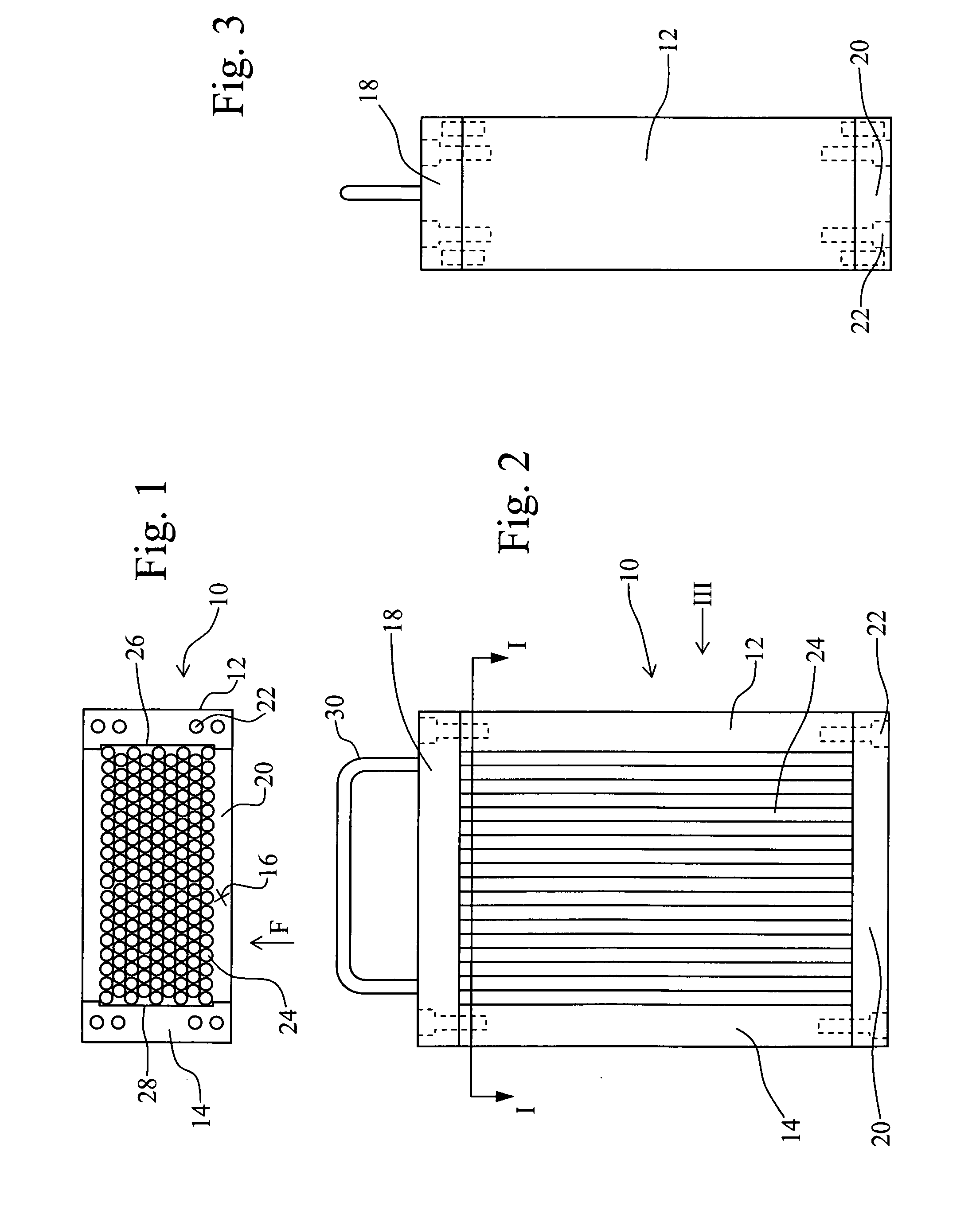

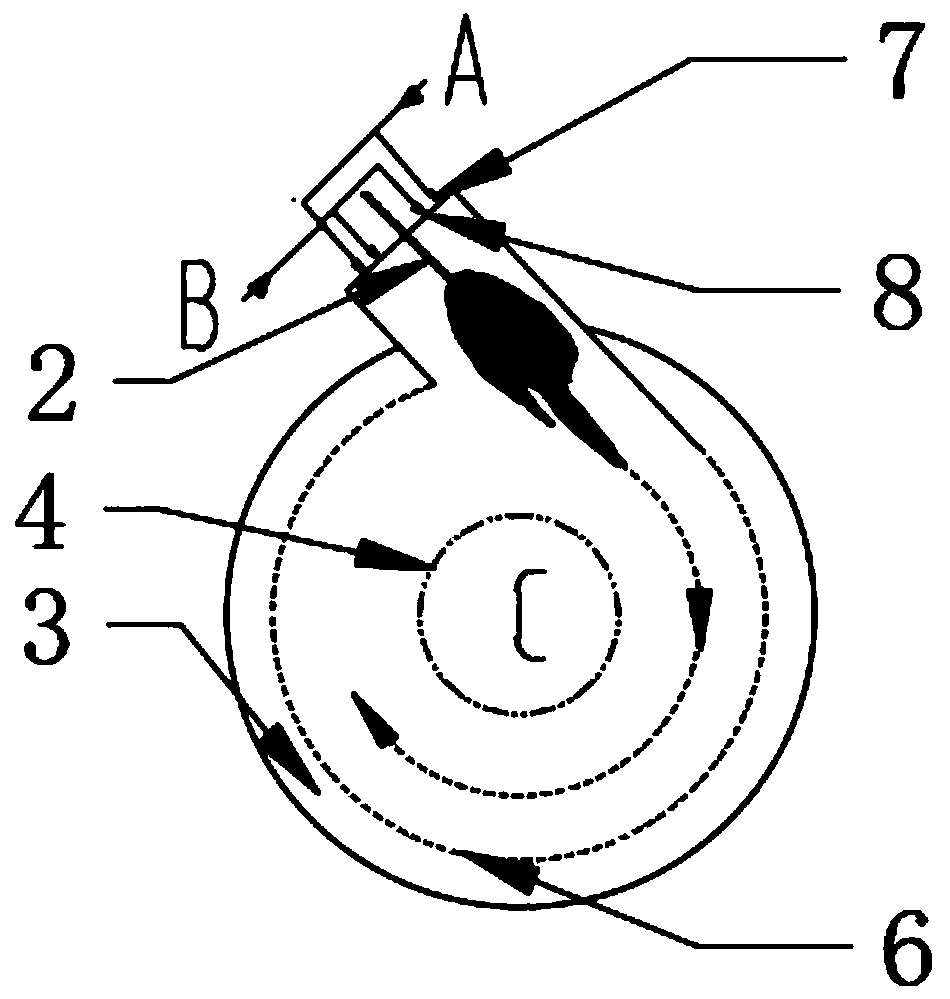

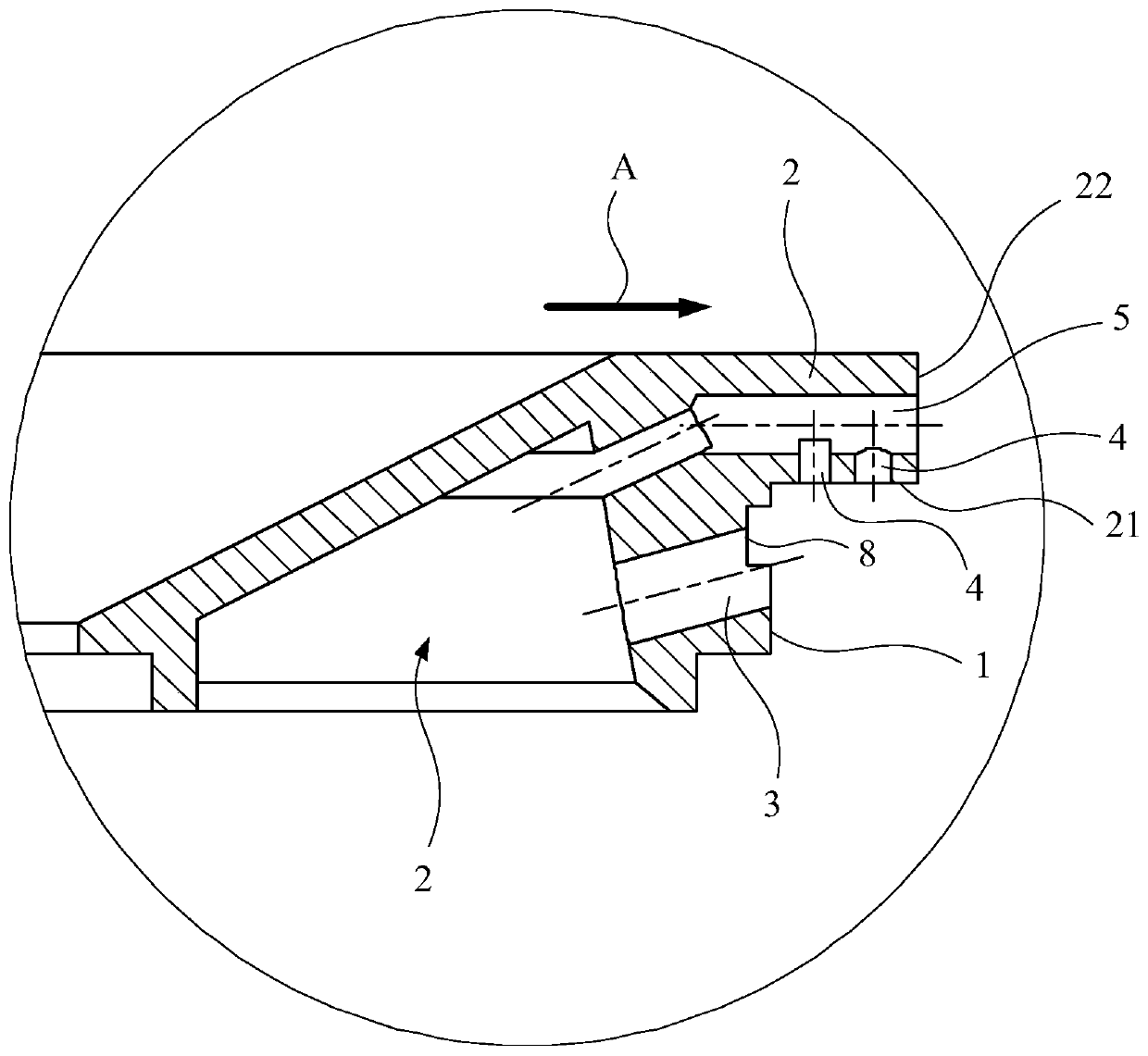

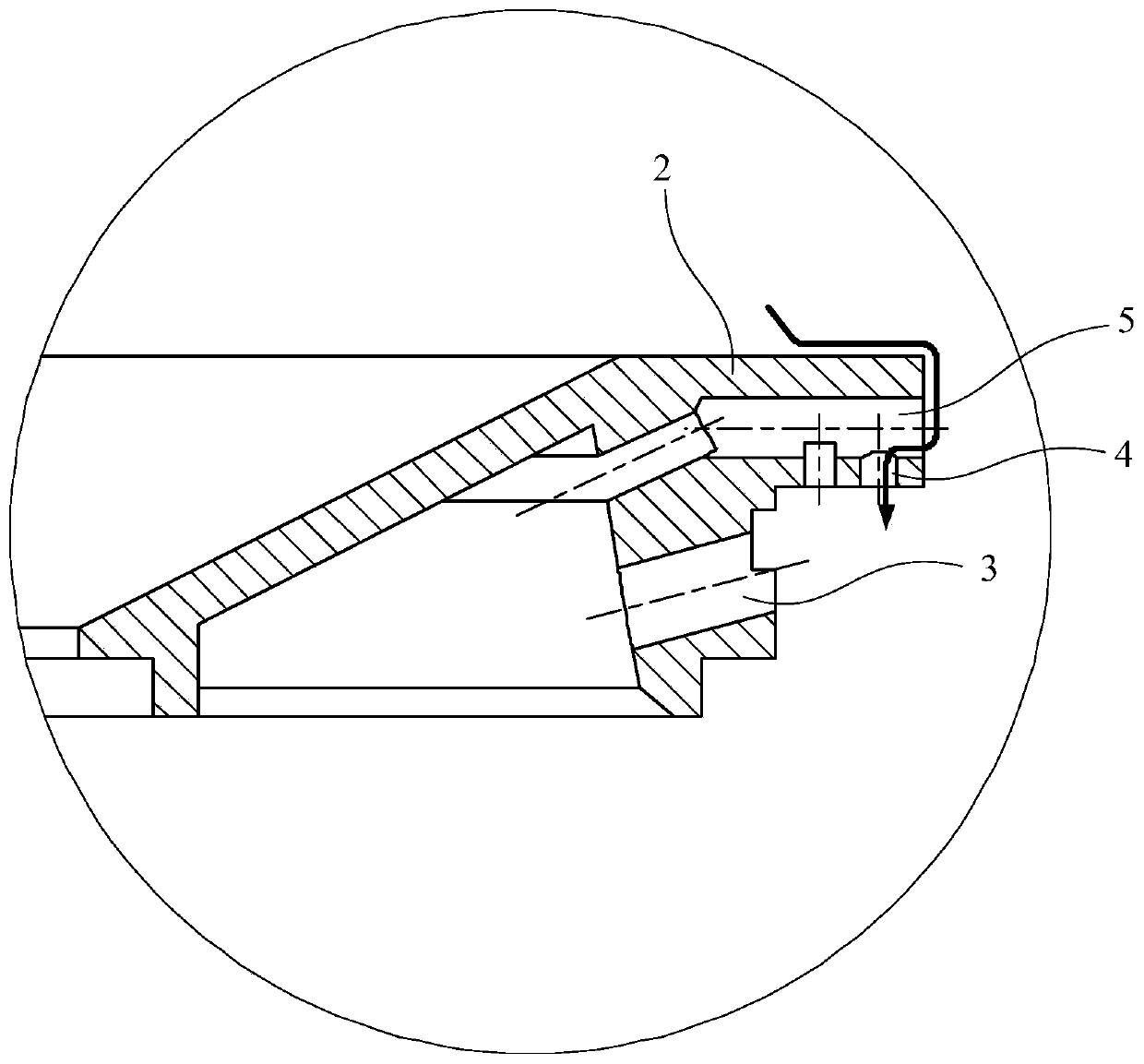

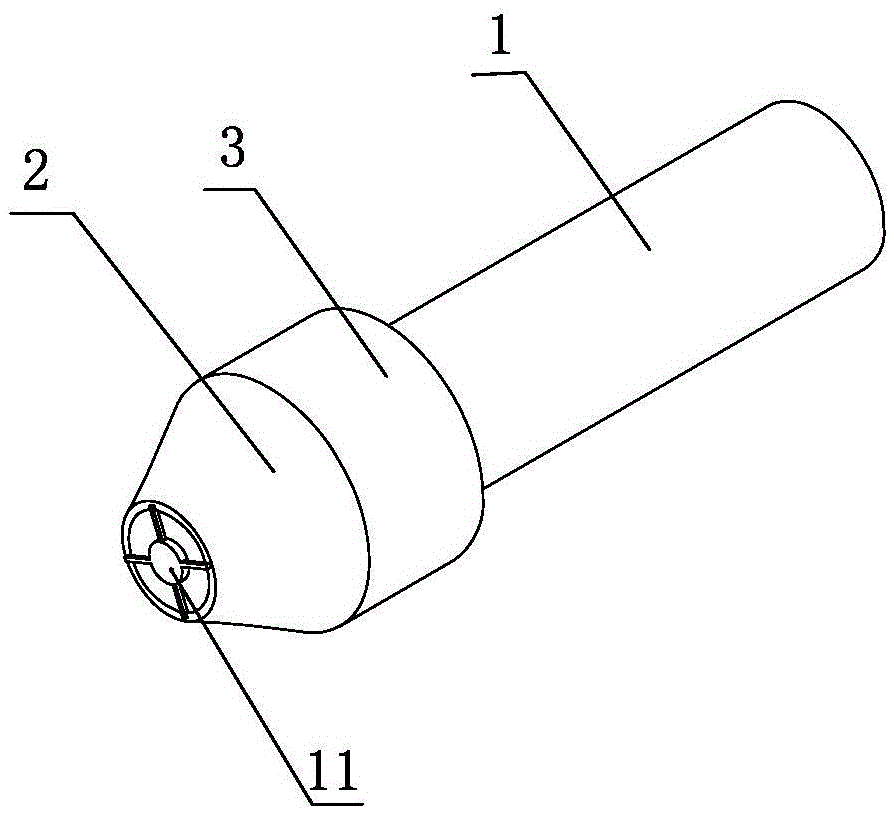

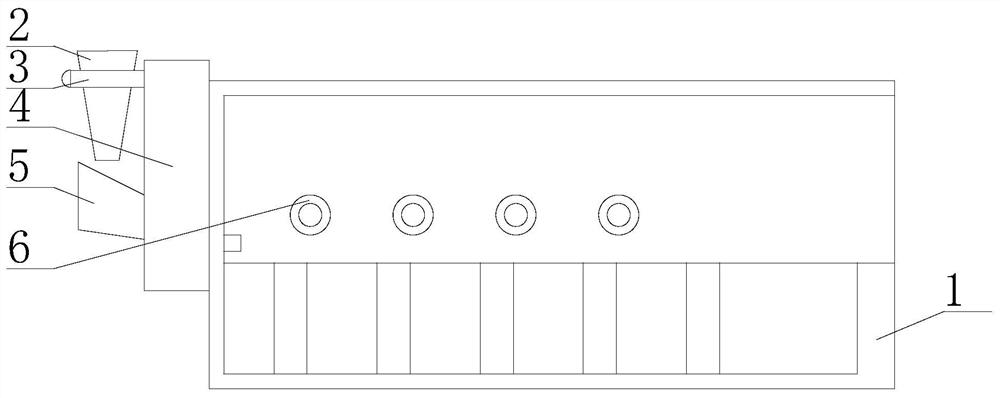

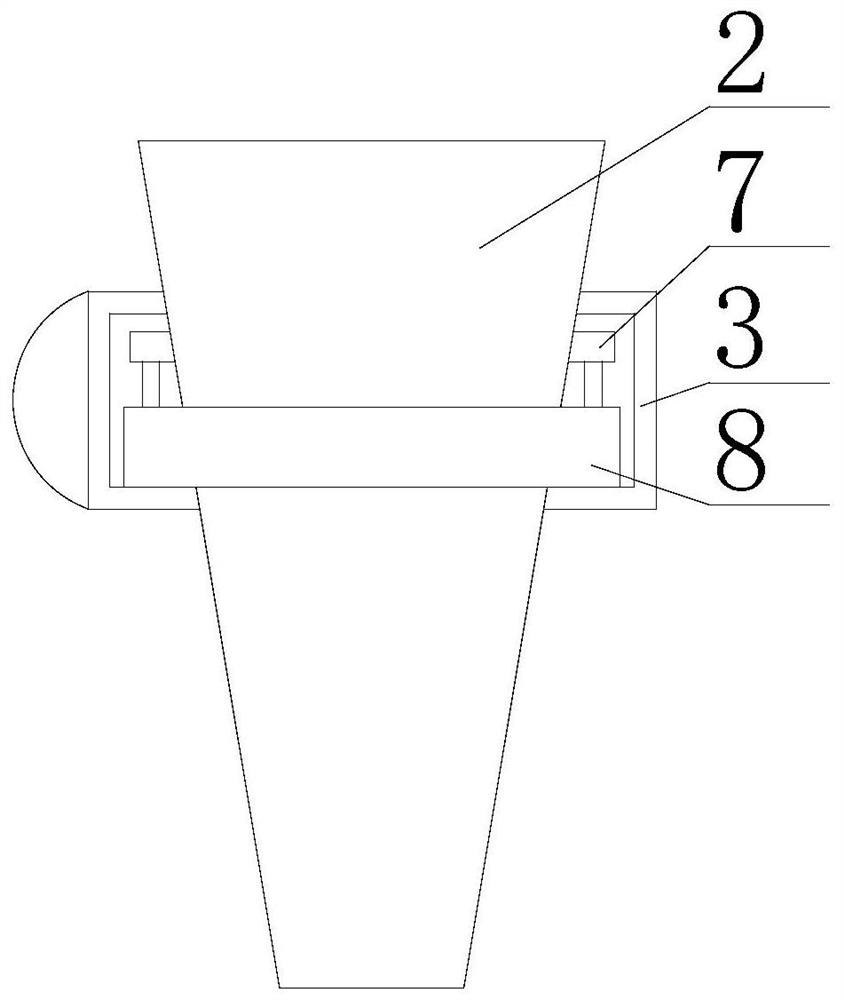

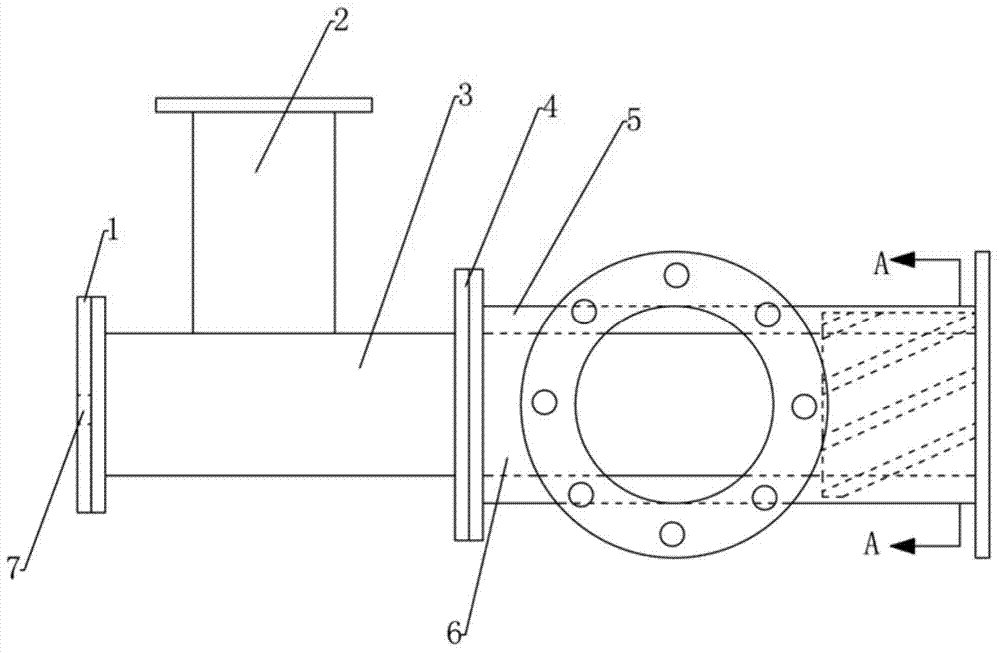

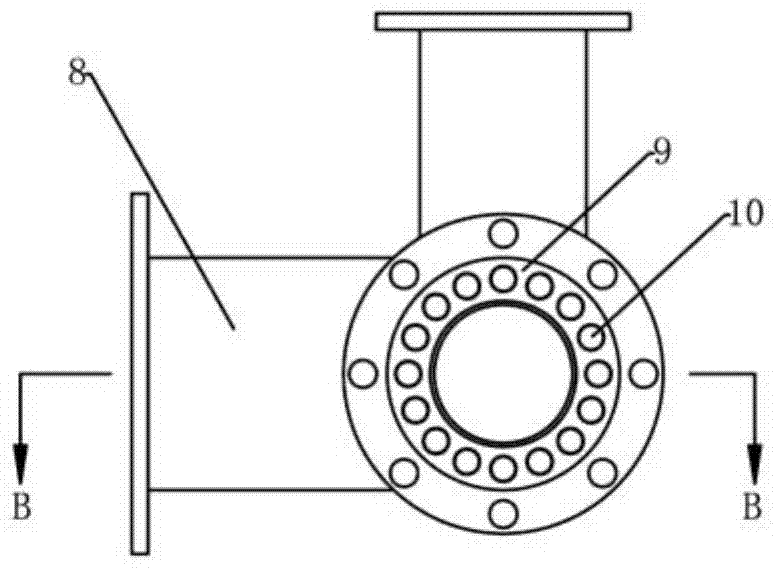

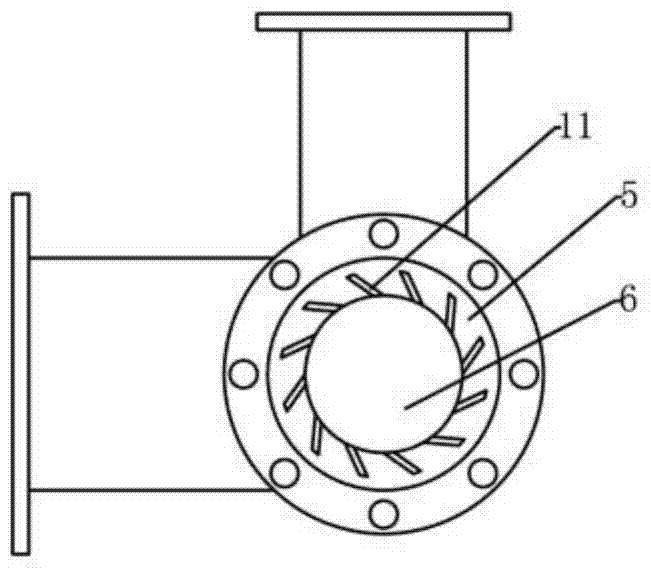

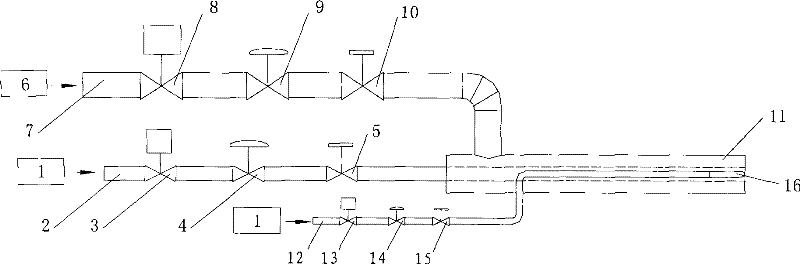

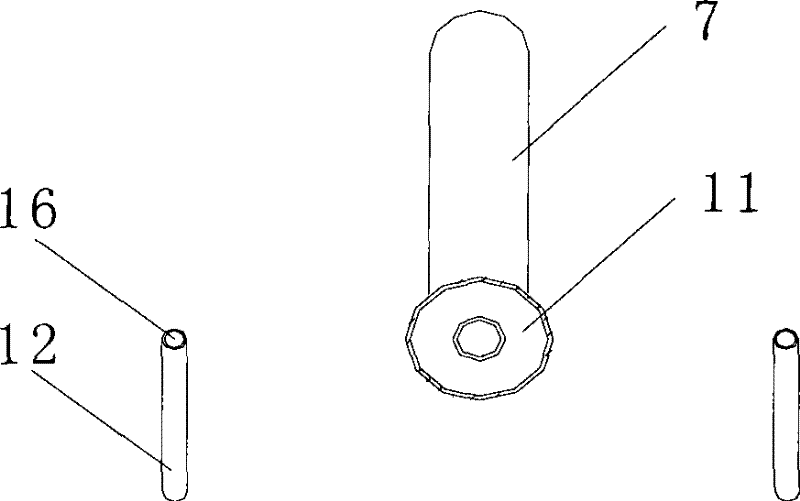

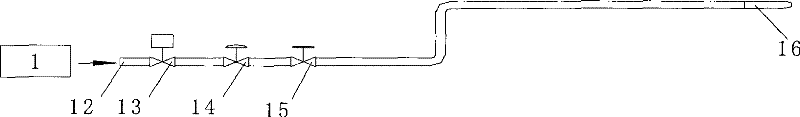

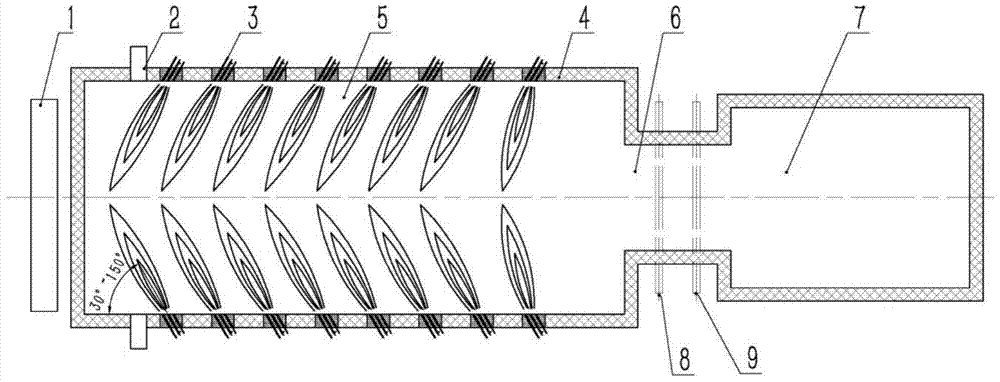

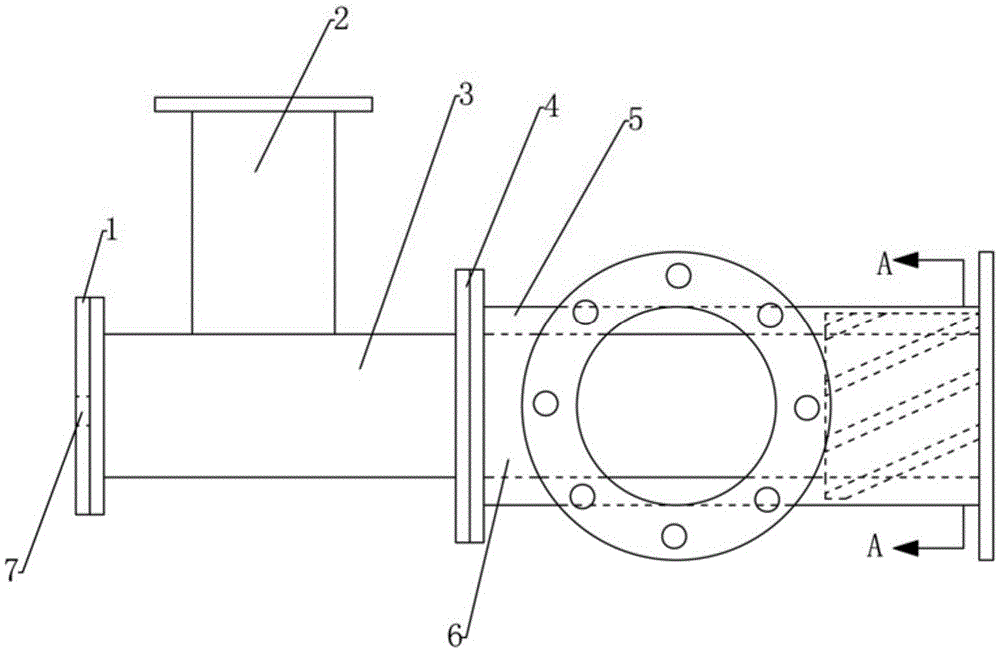

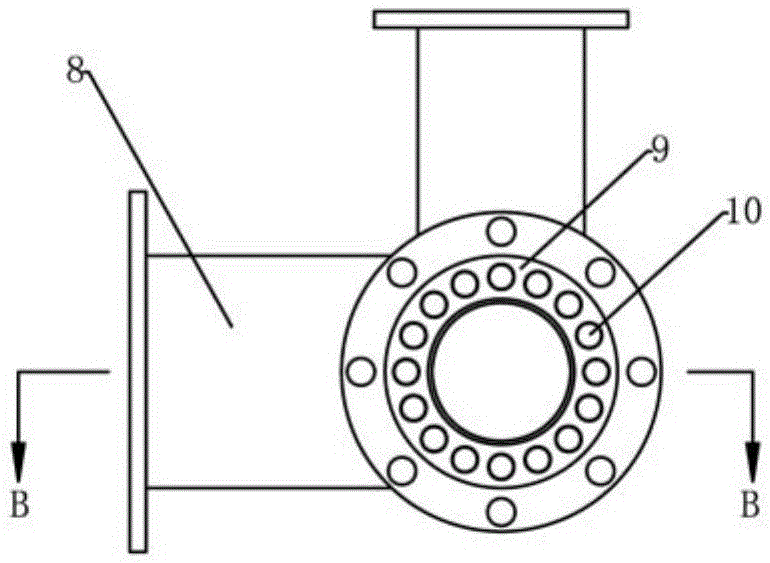

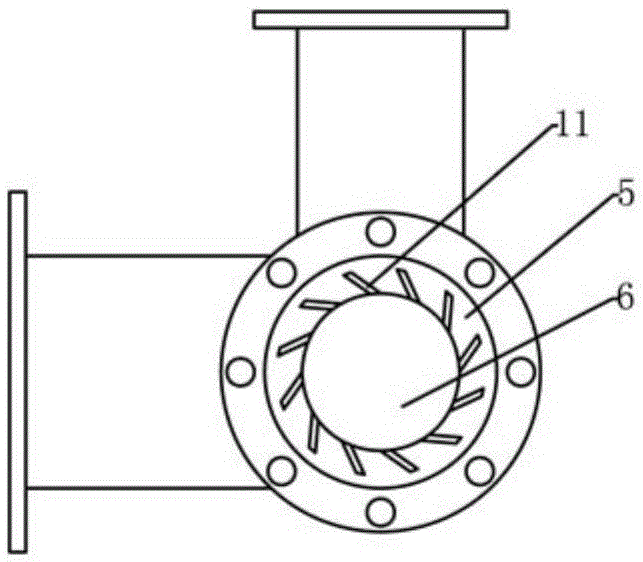

Fuel step adding apparatus of glass melter total oxygen combustion

InactiveCN101381196ASpread evenlyIncrease flame lengthGlass furnace apparatusCombustion regulationCombustorGlass melting

The invention provides a hierarchical adding device for total-oxygen combustion fuel of glass melting furnaces. The device mainly comprises a main fuel pipe (2), a combustion-supporting oxygen pipe (7), a main burner (11), minor fuel pipes (12), as well as valves which are connected with the bodies of the combustion-supporting oxygen pipe (7), the main fuel pipe and the minor fuel pipes and play a certain role in controlling and regulating, wherein the main burner (11) has a casing-type structure and is sleeved with the body of the right part of the main fuel pipe (2); two minor fuel pipes (12) are provided, are symmetrically distributed on two sides of the main burner (11), and are parallel to the main burner; and the right end of the body of the combustion-supporting oxygen pipe (7) is connected and communicated with the main burner through a bent pipe. The device regulates the length, coverage area, temperature and other parameters of flame by adjusting the amount of fuel used between the main burner and the two minor fuel pipes so as to ensure the complete combustion of the fuel, has the advantages of saving energy, reducing emission, benefiting environmental protection and the like, and is especially applicable to total-oxygen combustion glass melting furnaces which takes natural gas as fuel.

Owner:WUHAN UNIV OF TECH

High-temperature flue gas multi-stage backflow low-nitrogen combustor and combustion method thereof

PendingCN111023091AReduce the temperatureImprove stabilityGaseous fuel burnerThermodynamicsCombustor

The invention discloses a high-temperature flue gas multi-stage backflow low-nitrogen combustor and a combustion method thereof. The combustor comprises a shell, a fuel main pipe and a combustion head, wherein the fuel main pipe is arranged in the shell, and an air channel is formed between the fuel main pipe and the shell; the combustion head comprises a connecting pipe, a secondary fuel pipe, aprimary fuel pipe, a secondary fuel distribution ring pipe and a rotational flow disc; the secondary fuel distribution ring pipe is arranged on the periphery of the rotational flow disc in a concentric circle mode, and the secondary fuel distribution ring pipe and the rotational flow disc jointly serve as an outlet of the combustion head; and vortex plates are arranged on the inner wall surface ofthe front end of the shell, and the vortex plates are arranged at flue gas backflow holes in a one-to-one correspondence mode. Primary air and fuel gas enter the combustor through the air channel andthe fuel main pipe correspondingly; and the fuel gas is divided into primary fuel gas and secondary fuel gas through the primary fuel pipe and the secondary fuel pipe correspondingly. The primary fuel gas forms an on-duty flame at the center of the rotational flow disc. The secondary fuel gas and air form high-speed jet flow, and high-temperature flue gas is entrained to form multi-stage backflow. The high-temperature flue gas multi-stage backflow low-nitrogen combustor has the advantages of fuel grading, flame dispersion, low NOx combustion and the like.

Owner:TSINGHUA UNIV

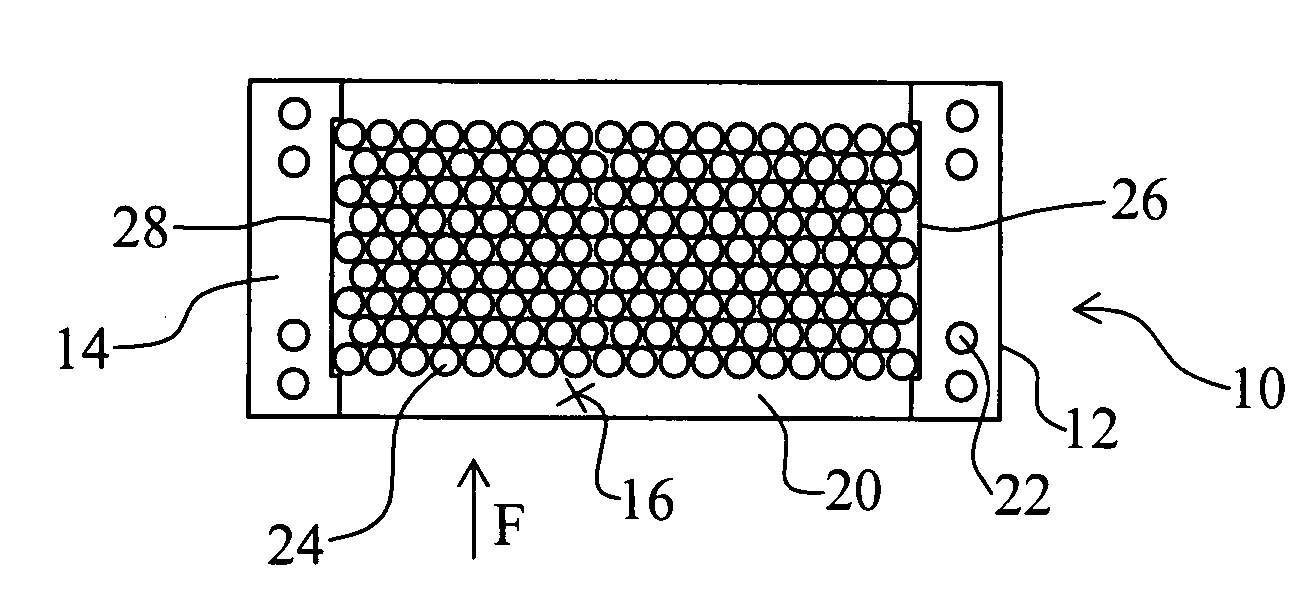

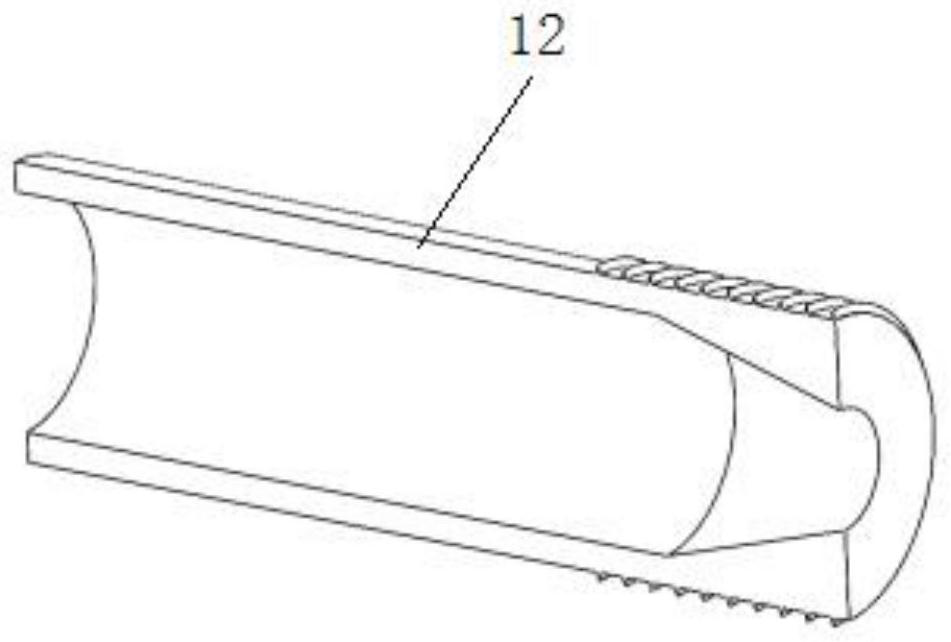

Flame arrester

InactiveUS20080164038A1Increase flow resistanceIncrease flame lengthFire rescueFire alarmsFlame arresterDetonation flame arrester

The flame arrester comprises a flow passage in which are disposed a plurality of generally aligned rods such that fluids flowing in the passage must pass between the rods. Rows of rods are used to construct the flame arrester element, ideally closely spaced and these present a natural surface over which air can flow with minimal flow resistance. The rods can be of any size and the gaps between them can be selected to arrest explosions due to different gases or vapours in air. The rod diameter can be altered to withstand different levels of explosion pressure, making it possible to construct both deflagration and detonation flame arresters. If tubes are used these can carry cooling fluid making the arrester more effective at coping with continuous burning. Rods in parallel rows can be offset with respect to the adjacent row. Suitable offset angles can vary.

Owner:READE CHARLES OSBORN

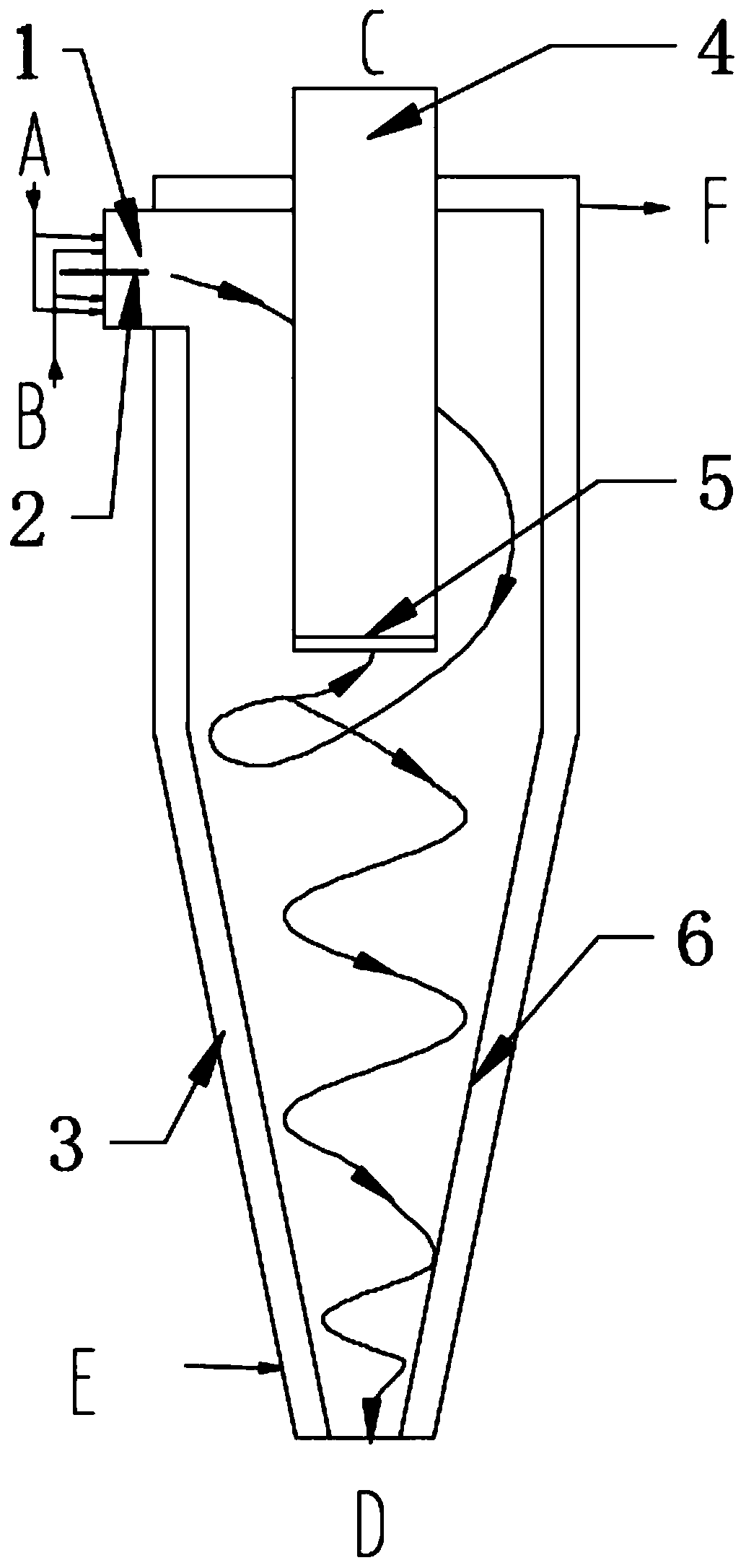

Supercritical hydrothermal combustion device and method

PendingCN111237784AFewer separation stepsMaximize processing powerIncinerator apparatusFiltration circuitsCombustion chamberSludge

A supercritical hydrothermal combustion device comprises a device body serving as a combustion chamber. A hydrothermal flame generator is arranged on the side face of the upper portion of the device body. Multiple high-pressure organic slurry nozzles and multiple high-pressure oxidizing agent nozzles are arranged on the hydrothermal flame generator. Igniters are arranged at outlets of the nozzles.A supercritical thermal fluid guide pipe penetrates into the device body from the top face of the device body. A residue slurry outlet is formed in the bottom of the device body. A residue separationassembly is arranged at the bottom of the supercritical thermal fluid guide pipe. Solid-phase residues generated by combustion of the hydrothermal flame generator and part of liquid phase products flow out from the residue slurry outlet, the rest of liquid phase products enter the supercritical thermal fluid guide pipe after being filtered by the residue separation assembly and flow out from a supercritical thermal fluid outlet at the top of the supercritical thermal fluid guide pipe, and the rough separation process of solid-phase and liquid-phase products is achieved. By means of the supercritical hydrothermal combustion device, rapid ignition, stable and clean combustion and afterburnt residue and flow efficient separation of fossil fuel (such as coal), urban / industrial sludge and other solid-phase or solid bearing fuel are achieved.

Owner:XI AN JIAOTONG UNIV

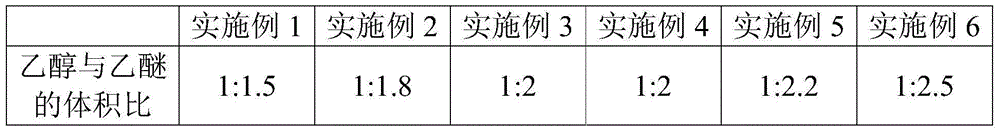

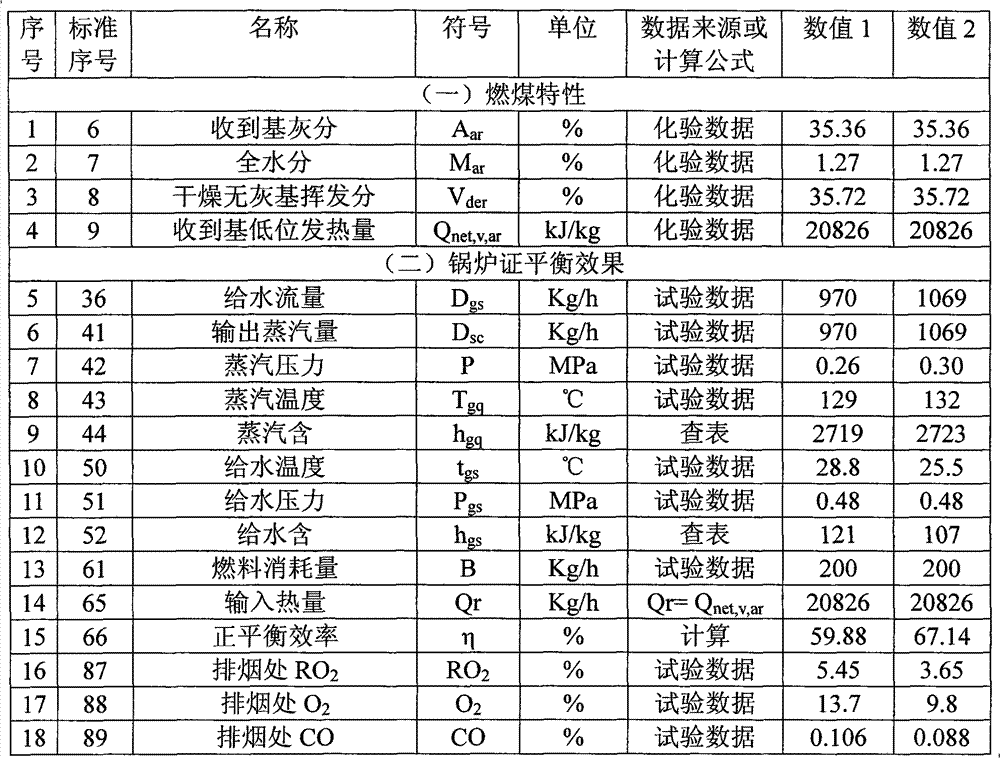

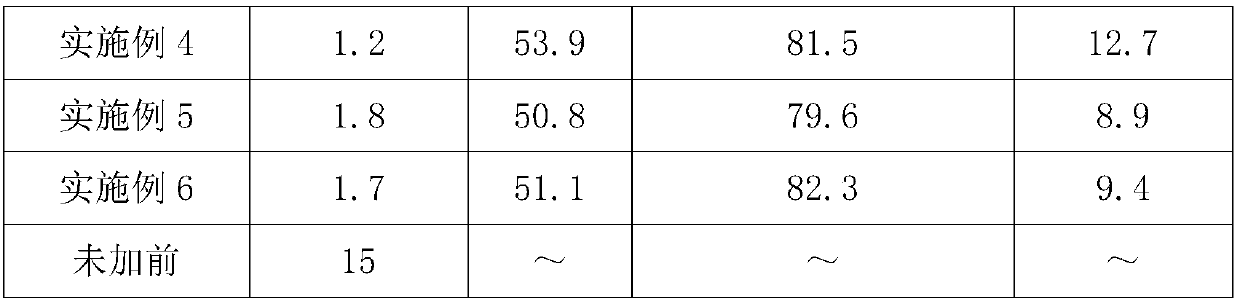

Environment-friendly coal-saving agent

InactiveCN104877730ASignificant coal saving effectReduce consumptionSolid fuelsSocial benefitsCombustion

The invention relates to the field of fire coal additive, in particular to environment-friendly coal-saving agent. The environment-friendly coal-saving agent includes 10 to 20 parts of combustion improver, 10 to 20 parts of oxygen supplier, 5 to 15 parts of catalyst, 0.8 to 1.6 parts of penetrating agent, 0.5 to 1.2 parts of dispersing agent, 1.6 to 3.2 parts of purificant and 0.8 to 3.2 parts of sulfur-fixing agent by weight. The environment-friendly coal-saving agent is obvious in coal saving effect, the coal saving effect can arrive at 24.35%, the coal consumption is reduced, the emission of carbon dioxide and the like harmful gas is greatly reduced, and the economical benefit and social benefit are high; the harmful gas is reduced by more than 70%, and the Greenman blackness is less than 1 grade.

Owner:ZHANGJIAGANG WUHU NEW MATERIAL TECH DEV

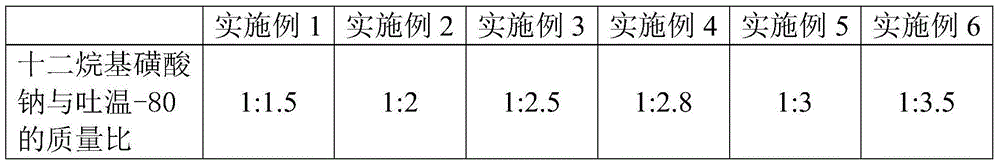

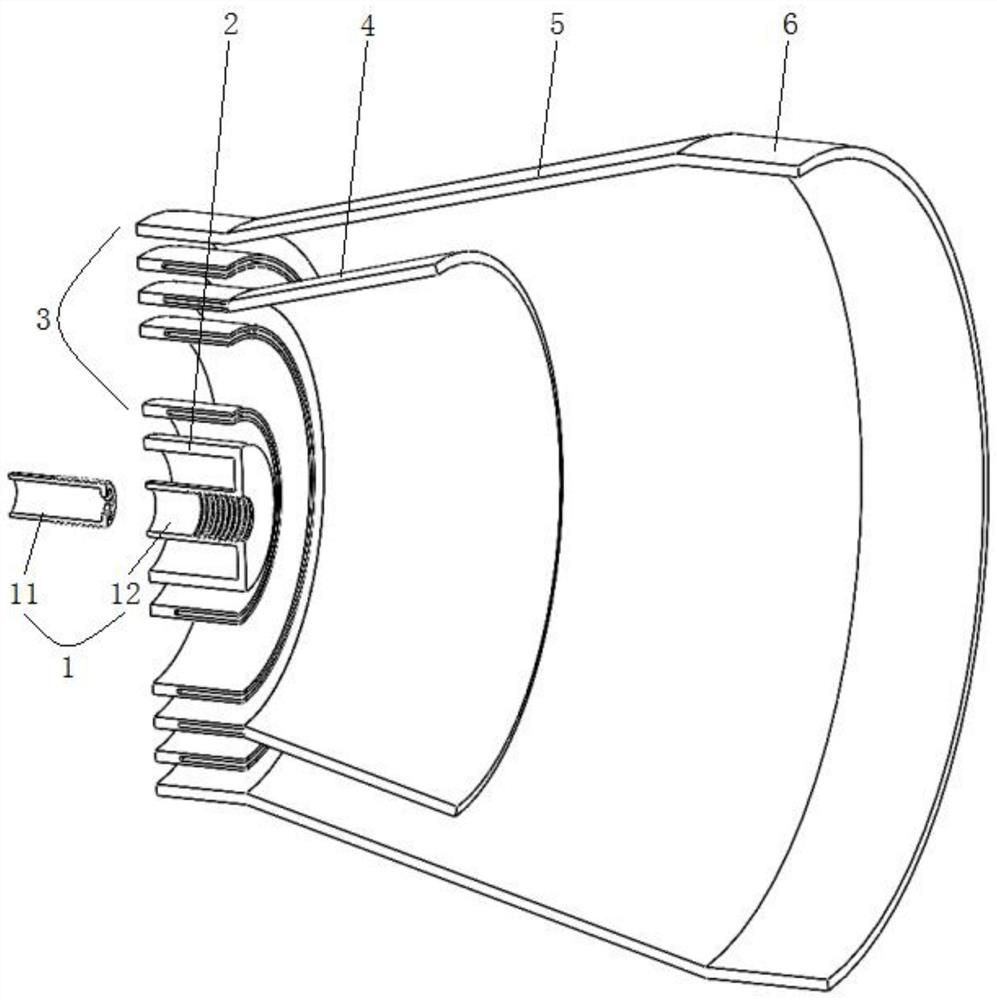

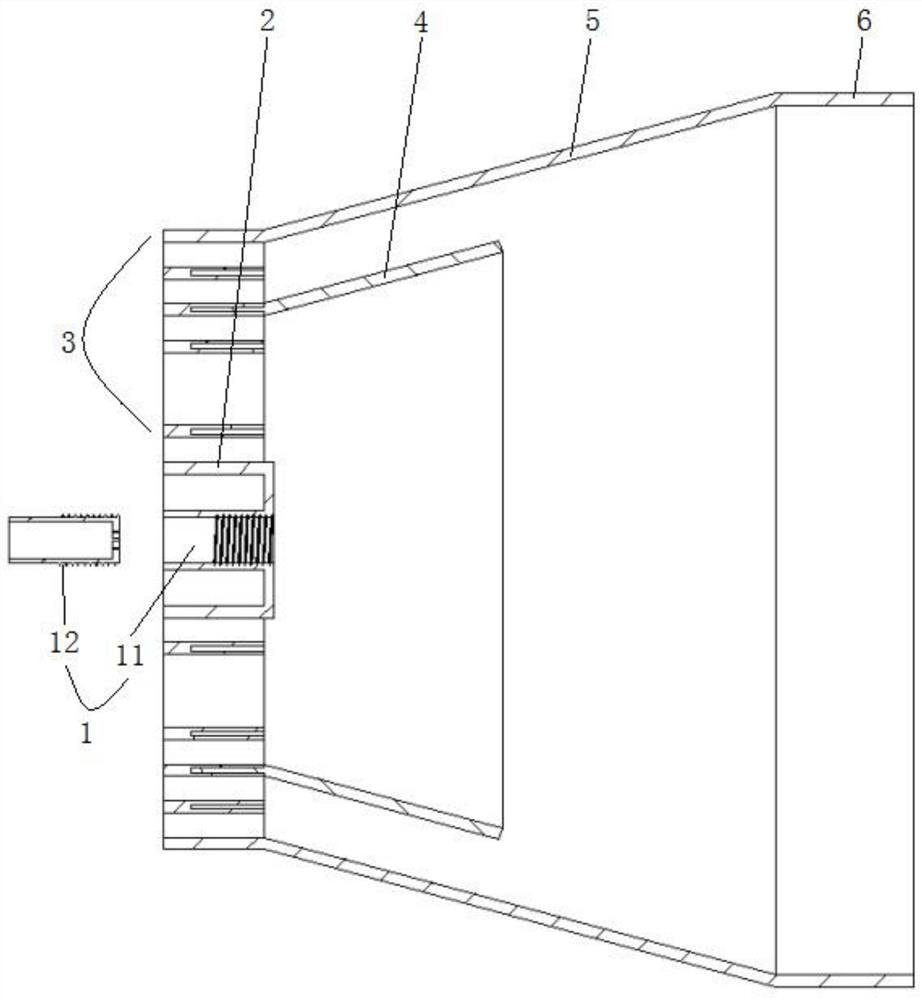

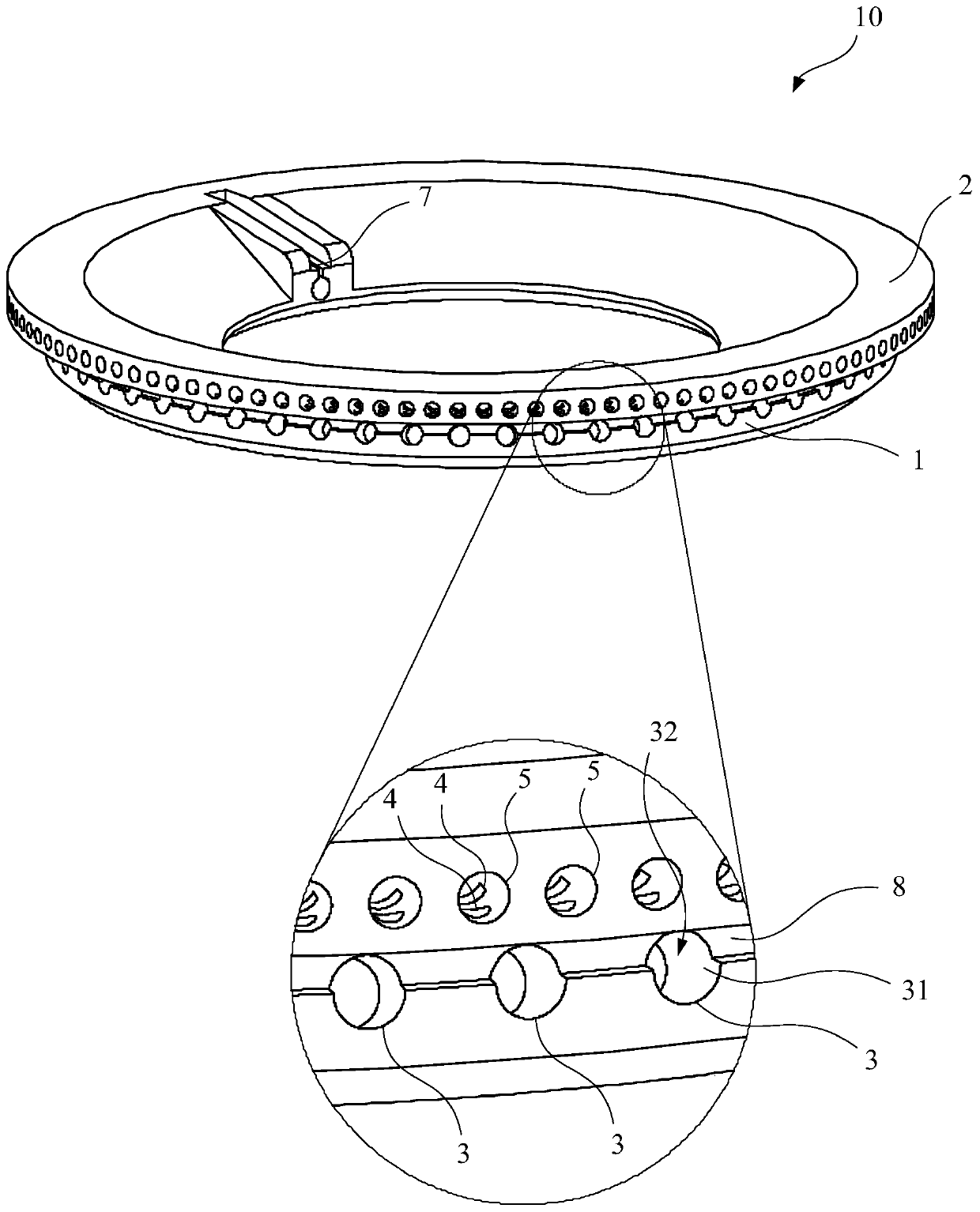

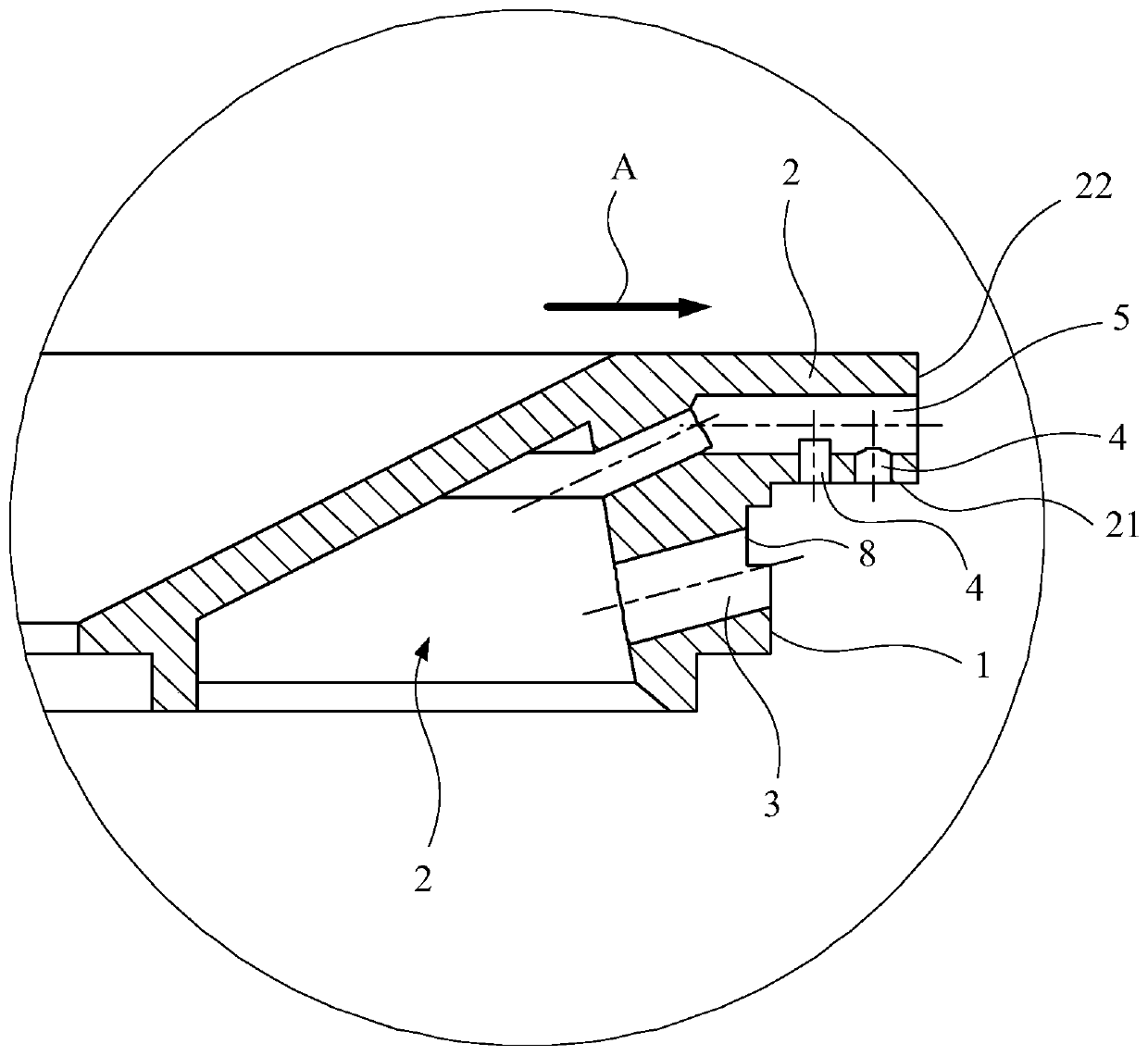

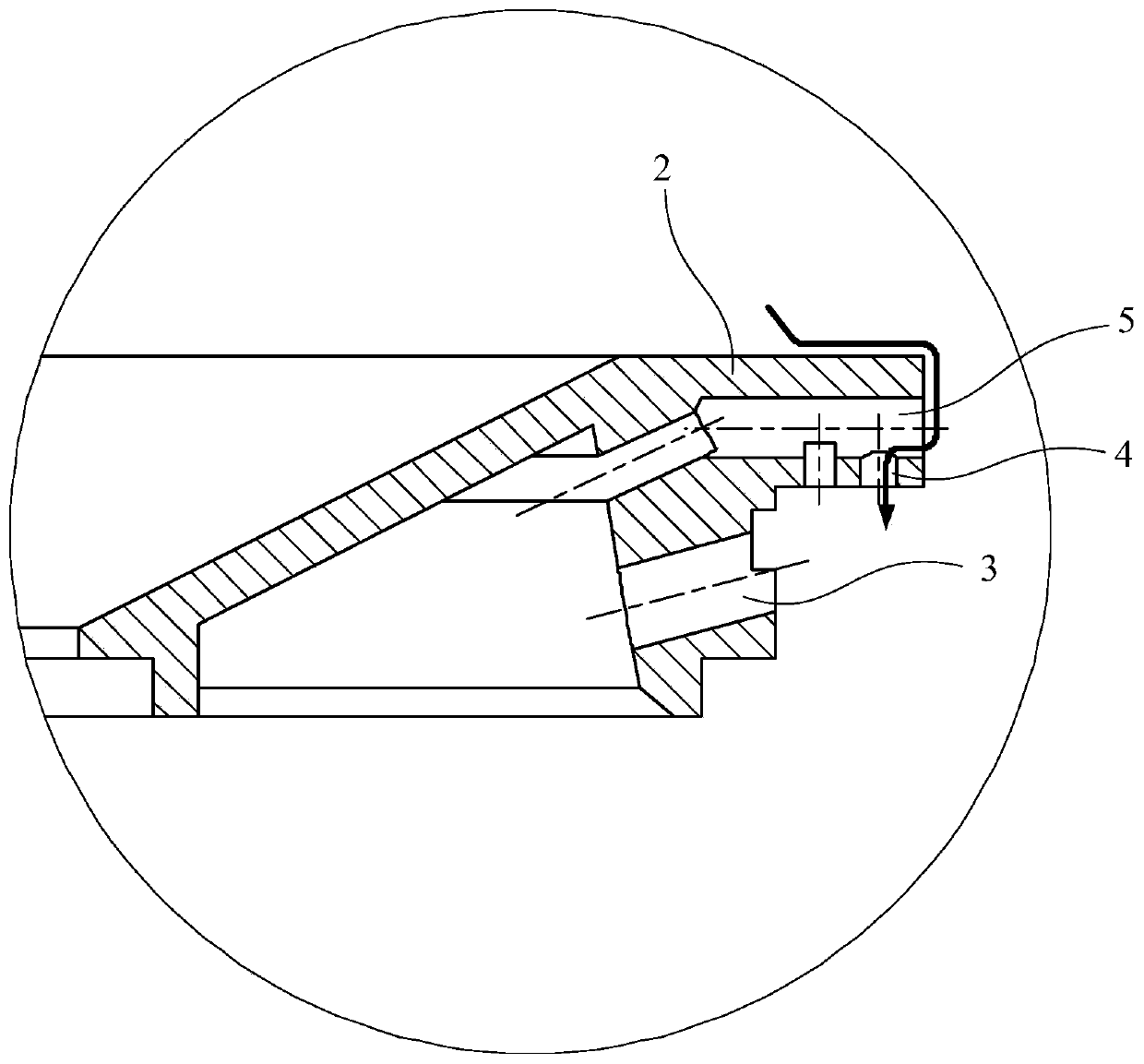

Stove fire cover

ActiveCN110220195AImprove heating efficiencyIncrease flame lengthBurner safety arrangementsDomestic stoves or rangesEngineeringHeating efficiency

The invention discloses a stove fire cover. The side wall of the stove fire cover is provided with an outward extending waterproof brim. The stove fire cover is provided with main fire holes and flamestabilizing holes. The main fire holes are distributed in the side wall and located below the waterproof brim. The flame stabilizing holes are formed in the lower surface of the waterproof brim towards the main fire holes. According to the stove fire cover, the flame stabilizing holes for stabilizing flames of the main fire holes are formed in the specific positions of the lower surface of the waterproof brim so that the length of the flames of the main fire holes located in the lower end of the waterproof brim can be increased, the flames can further outwards extend, and accordingly, under the situation that the extending length of the waterproof brim is large, the flames can be prevented from being hindered by the waterproof brim, so that the heating efficiency of the stove fire cover is improved, and meanwhile the off-flame situation can be avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Environment-friendly coal saving agent

The invention discloses an environment-friendly coal saving agent composed of the following substances in parts by weight: 15-18 parts of catalyst, 20-25 parts of modifier, 5-10 parts of smoke suppressor, 15-20 parts of purificant, 1-3 parts of combustion improver, 2-6 parts of expanding agent and 10-15 parts of sulphur-fixing agent. All the components of the environment-friendly coal saving agent disclosed by the invention are matched with each other to change smoke generated in the coal combustion process into coal gas to be combusted together with coal, so that the flame is hugely increased, and the flame length, the combustion density and the combustion area are greatly increased, thus the efficiency of a boiler is increased, a great deal of coal is saved, a great deal of discharged smoke and harmful gas are reduced, and the double effects of saving energy and protecting the environment are achieved.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

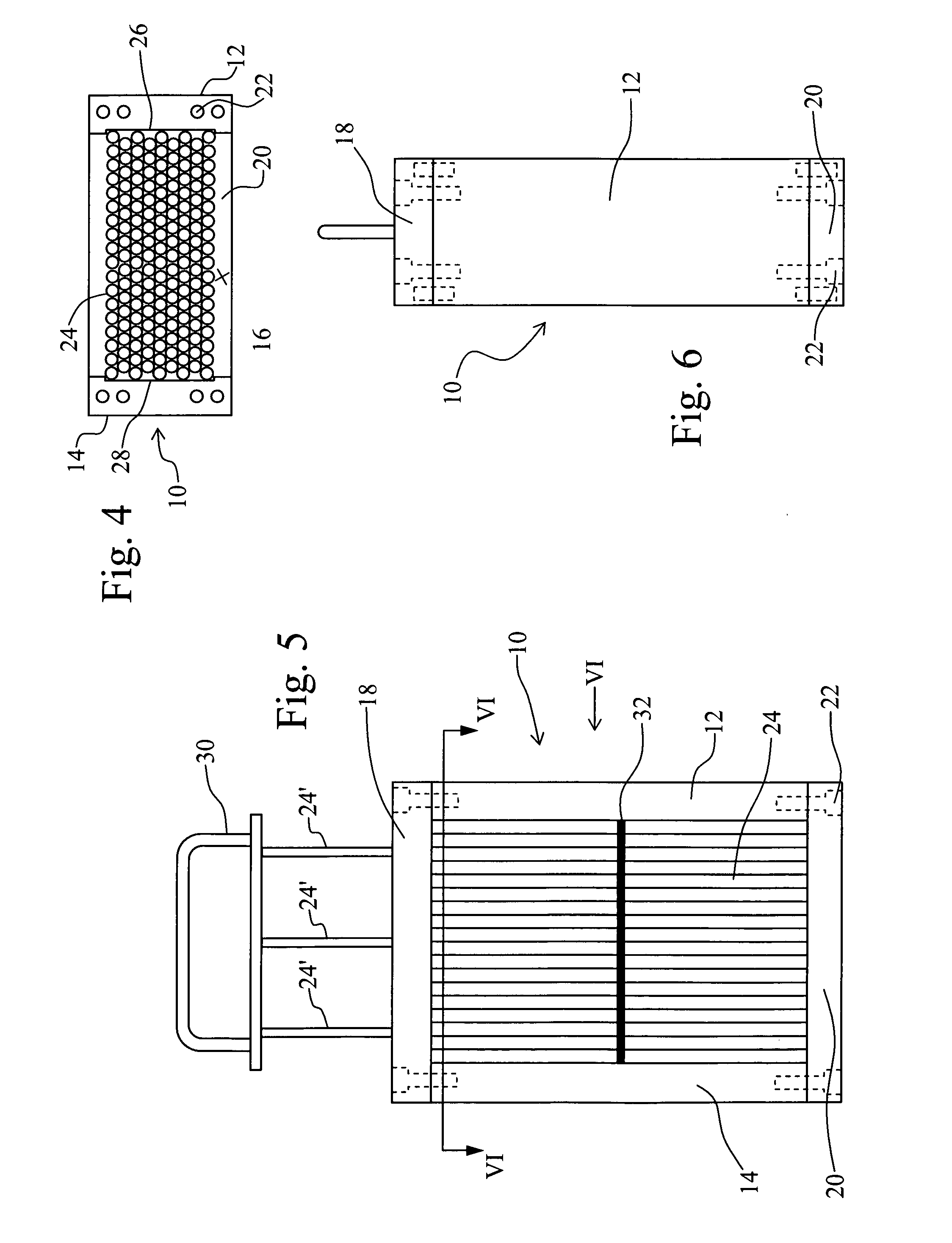

Multi-channel dense-thin separation type single cone burner and using method thereof

PendingCN111895398AIncrease mixing rateFire stablePulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to a multi-channel dense-thin separation type single cone burner and a using method thereof. The burner comprises a pulverized coal supply mechanism, a transition channel, a multi-stage air assembly, at least one deflector, a combustion stabilizing chamber and a rectifying chamber, wherein the multi-stage air assembly comprises N air ducts, the Nth air duct is connected withthe combustion stabilizing chamber and the rectifying chamber sequentially, the pulverized coal supply mechanism comprises an air and pulverized coal pipe and a reach-lean separator, the air and pulverized coal pipe communicates with the combustion stabilizing chamber, the reach-lean separator is detachably connected to the air and pulverized coal pipe, and the transition channel is arranged at aninterval in the first air duct; each air duct is of a double-layer hollow structure, and one end of at least one deflector is inserted into the corresponding air duct; and at least one direct flow channel is formed between each deflector and the combustion stabilizing chamber, a flare is formed at the other end of each deflector, and the angle of each flare is the same as that of the combustion stabilizing chamber. Air can be divided into N strands to enter a burner body, turbulence intensity at the airflow boundary is high, the mixing speed of air and pulverized coal is increased, the pulverized coal is stably ignited, and high-efficiency and low-nitrogen burning of the pulverized coal can also be ensured.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Environment-friendly coal-saving modifier

The invention discloses an environment-friendly coal-saving modifier which is prepared from the following components in parts by weight: 9-15 parts of catalyst, 25-30 parts of elm wood dust powder, 36-45 parts of camphor tree wood dust powder, 12-16 parts of oak wood dust powder, 9-14 parts of isocyanate, 3-9 parts of urea-formaldehyde resin, 10-15 parts of plant fiber, 2-9 parts of mixed solvent, 5-20 parts of inorganic thickener, 5-10 parts of toughener, 1-3 parts of combustion improver and 10-15 parts of sulfur-fixing agent. The environment-friendly coal saving agent can convert flue gas generated in the coal combustion process into coal gas due to the interaction among the components; when being together combusted with coal, the coal saving material can enhance the flame, reduces the discharge of abundant smoke dust and harmful gas, and has the dual effects of energy saving and environment protection.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

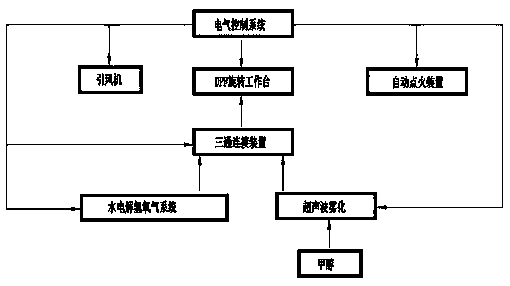

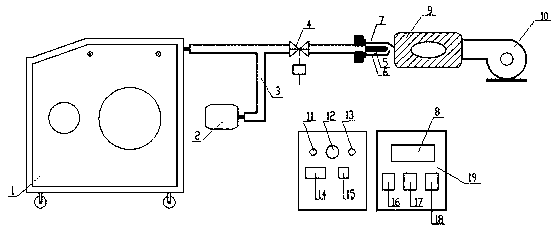

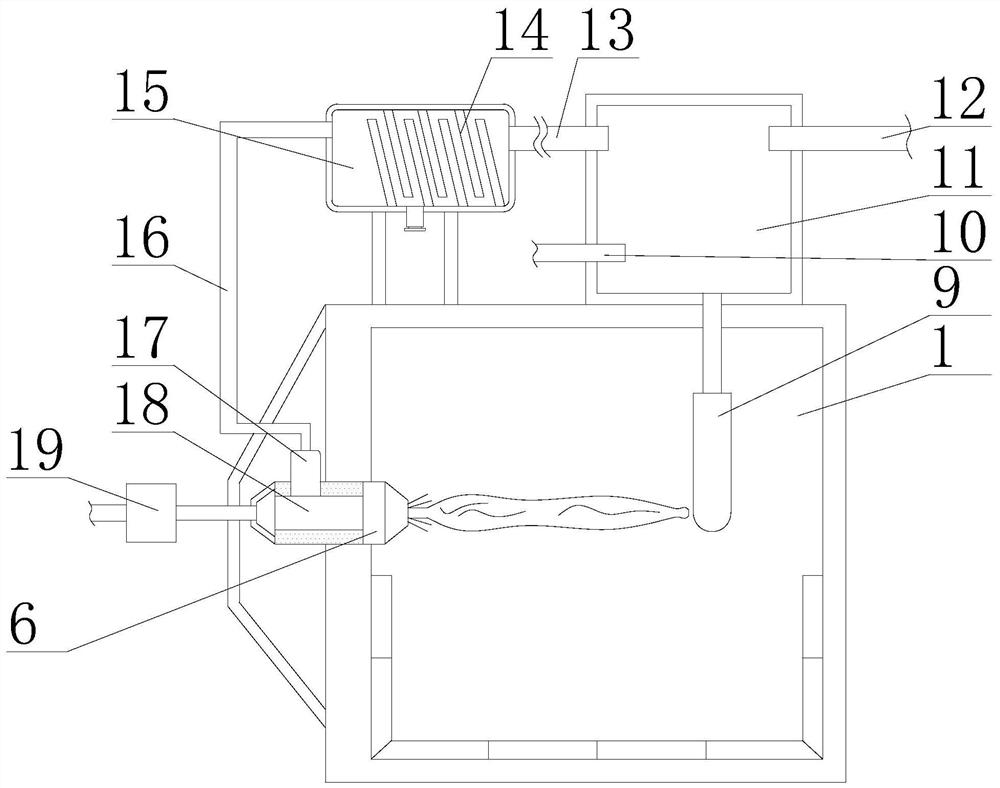

Decarbonization method and device for diesel engine exhaust gas carbon granule collector

PendingCN110107380AReduce the temperatureWon't hurtExhaust apparatusSilencing apparatusEngineeringCarbon deposit

The invention discloses decarbonization method and device for a diesel engine exhaust gas carbon granule collector (Diesel Particulate Filter, DPF). The decarbonization method comprises the steps of producing an oxyhydrogen gas through water electrolysis, mixing the oxyhydrogen gas with methyl alcohol subjected to ultrasonic atomization, combusting under the control of an automatic methyl alcohol,ejecting through a fire nozzle, utilizing an induced draft fan on the back part of a DPF rotating work table for forming an air channel, enabling an induced draft fan for combusting and cleaning theinner wall of the carbon granule collector, combusting and melting carbon deposits on the inner wall of the carbon granule collector by utilizing the catalytic combustion characteristics of activatedhydrogen ions and hydroxyl ions, and discharging under the washout of moisture formed after hydroxyl ion combustion. The decarbonization method provided by the invention has the advantages of high decarbonization efficiency, no damage on the inner wall of the carbon granule collector, low us cost, no pollution on the environment and the like. The device provided by the invention comprises an oxyhydrogen gas oxyhydrogen gas system, a methyl alcohol ultrasonic atomization device, a three-way connector, an automatic igniter, a combustion nozzle, the DPF rotating work table, the induced draft fanand an electrical control device.

Owner:湖南冠拓科技股份有限公司

Green environment-friendly coal saving material

The invention discloses a green environment-friendly coal saving material which is characterized by comprising the following components in parts by weight: 20-30 parts of catalyst, 14-16 parts of modifier, 7-9 parts of smoke suppressor, 1-9 parts of cleansing agent, 5-20 parts of inorganic thickener, 5-10 parts of toughener, 5-15 parts of flame retardant, 2-4 parts of mica powder, 1-6 parts of kieselguhr, 0.5-1.5 parts of ceramic powder, 3-10 parts of n-butanol, 6-9 parts of dimethylbenzene, 1-3 parts of pigment, 5-10 parts of smoke suppressor, 15-20 parts of cleansing agent and 10-15 parts of sulfur-fixing agent. By interactions among the components of the environment-friendly coal saving agent disclosed by the invention, flue gas generated in the coal combustion process is converted into coal gas, and the coal gas and coal are combusted together, so that the flame is enlarged severely, thereby reducing the discharge of abundant smoke dust and harmful gas and having the dual effects of energy saving and environment protection.

Owner:QINGDAO GUOQIANG ENVIRONMENTAL PROTECTION TECH

Environment friendly coal-saving agent

InactiveCN101486939BReduce the frequency of dust removalImprove efficiencySolid fuelsFuel additivesSuppressorSulfur

The invention discloses an environmental-protection coal saving agent and relates to a coal saving agent, which solves the defects that the existing coal saving agent has large additive amount, pollutes the environment and does not meet the Greenman blackness. By weight percentage, the environmental-protection coal saving agent comprises 5 to 10 percent of activator, 30 to 40 percent of modifier,5 to 10 percent of smoke suppressor, 5 to 10 percent of purificant, 2 to 8 percent of oxidant, 30 to 35 percent of swelling agent and 5 to 10 percent of sulfur fixing agent. The environmental-protection coal saving agent has the advantages of small additive amount, environmental protection, wide application scope and simple use. The additive amount of the coal saving agent is only 3 permillage ofthe weight of coal, but the energy-saving rate reaches more than 10.81 percent; and the harmful gas is reduced more than 70 percent and the Greenman blackness is less than 1 class.

Owner:HEILONGJIANG WEIDE ENERGY SAVING TECH DEV

Plant material composite coal-saving agent

InactiveCN104046404AImprove efficiencyEmission reductionSolid fuelsCross-linkEnvironmental resistance

The invention discloses a plant material composite coal-saving agent which is characterized by being prepared from the following substances in parts by weight: 25-26 parts of cis-butenedioic acid, 14-20 parts of acrylic stearate, 16-18 parts of mulberry wood powder, 3-8 parts of a sulphur-fixing agent, 3-8 parts of octadecanoic acid, 2-8 parts of cross-linking agent sulfur, 10-20 parts of an emulsion, 5-9 parts of titanium dioxide, 5-9 parts of diatomite, 3-7 parts of quartz sands, 6-9 parts of wood fibers, 5-8 parts of graphite powder and 2-6 parts of swelling agent. Components of the environment-friendly coal-saving agent disclosed by the invention are matched with each other, and smoke generated in the coal combustion process is converted into a coal gas which is jointly combusted with coal, so that the flame soars. Furthermore, discharge of a lot of soot and harmful gases is reduced, so that a double effect of saving energy sources and protecting the environment is realized.

Owner:QINGDAO GUOHANG XIANGYU TECH SERVICE

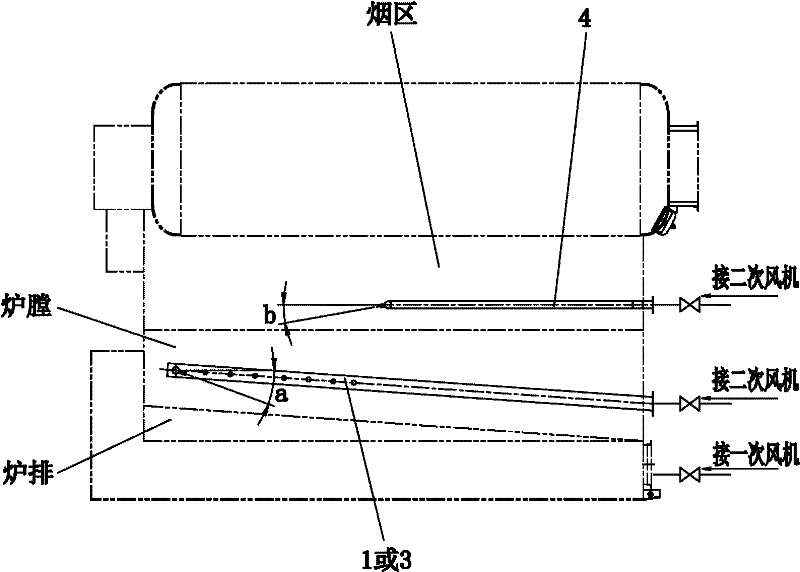

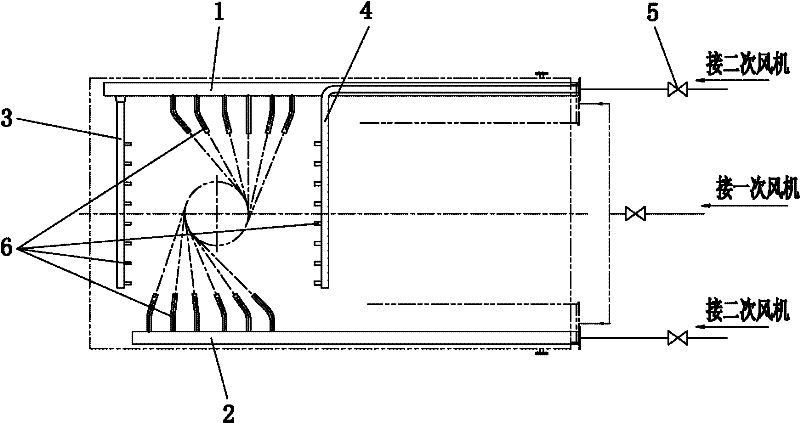

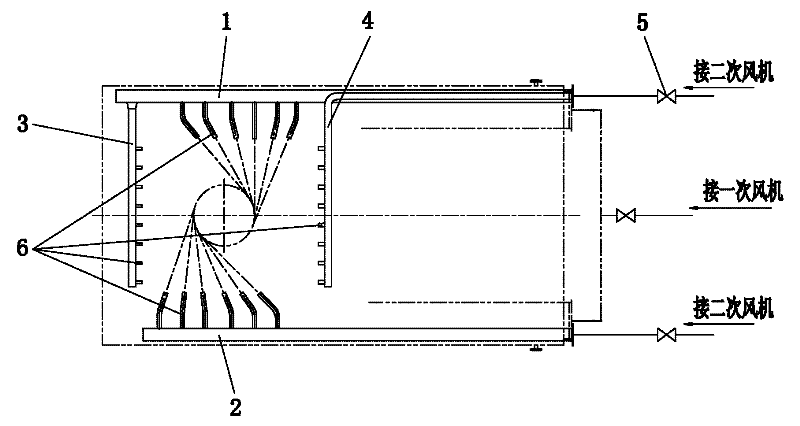

Biomass steam boiler secondary air distribution system

InactiveCN102261668AImprove efficiencyPromote environmental protectionNon-combustible gases/liquids supplyDistribution systemBiomass particle

The invention discloses a secondary air distribution system of a biomass steam boiler, which is composed of a left air pipe, a right air pipe, a front wall air pipe and a rear arch air pipe, and the left air pipe and the right air pipe are arranged on the grate above and longitudinally arranged on the left and right sides of the fire grate, the front wall air duct is arranged above the fire grate and horizontally arranged below the front wall of the furnace, and the rear arch air duct is horizontally arranged in the smoke area and arranged above the rear arch of the furnace , on the fire-facing surfaces of the left air duct, right air duct, front wall air duct and rear arch air duct located in the combustion center of the furnace, there are several air nozzles facing the combustion center of the furnace. The air duct on the left side and the air duct on the right side spray air to the left and right of the combustion center, and the air duct on the front wall and the rear arch air duct spray air to the front and rear of the combustion center, so that the combustion of biomass particles and air can be fully combusted, reducing the excess air coefficient. Reduced black smoke.

Owner:GUANGZHOU DEVOTION THERMAL TECH

Efficient flame burner

The invention relates to an efficient flame burner. The problems that combustible gas jetted by a burner is insufficient in combusting, and the length of flames is not enough are solved. The efficient flame burner comprises a sleeve, a gas mixing mechanism and a jetting pipe; the sleeve comprises a gas pipe and a combustion-supporting pipe, the tail end of the gas pipe is communicated with a volatilization pipe, and through holes are evenly formed in the periphery of the volatilization pipe; and the gas mixing mechanism comprises a fairing and a rotating wheel, wherein the fairing comprises a rear fairing body and a front fairing body. The rear fairing body is fixedly welded to the tail end of the combustion-supporting pipe through a connecting pipe; and the rotating wheel comprises a supporting frame and blades, the jetting pipe is of a conical hollow structure, and a flow guide piece is arranged at the front end of the jetting pipe. The problem that insufficient mixing is caused by parallel blowing of two strands of air flows of combustion-supporting gas and combustible gas is solved, and the combustible gas can be sufficiently combusted.

Owner:SHANDONG IRON & STEEL CO LTD

Automatic control device of glass kiln

InactiveCN111847840AIncrease air intakeIncrease flame lengthCharging furnaceGlass furnace apparatusAutomatic controlEngineering

The invention relates to the technical field of glass kiln control equipment. The invention further discloses an automatic control device of a glass kiln. The automatic control device comprises a kilnbody, a side face supporting plate is fixedly mounted on the left side face of the kiln body, a weighing supporting base is fixedly mounted on the left side of the side face supporting plate, a cylindrical measuring scale is fixedly mounted at the bottom of an inner cavity of the weighing supporting base, and a supporting sleeve base is fixedly connected to the top of the cylindrical measuring scale. According to the automatic control device of the glass kiln, a sealing steel cylinder is arranged in the kiln body, a gas storage box is arranged above the kiln body, and a gas bag is matched with a spring, so when the flame length of a flame spray gun cannot touch the sealing steel cylinder, the temperature of the sealing steel cylinder is reduced, and thus the gas bag communicated with thegas storage tank is compressed, a valve plate is driven by the spring to move, the gas inflow amount of the valve seat is increased, the flame length is increased until a balance state is achieved, and the flame length can be quickly and accurately controlled.

Owner:来安县华阳玻璃制品有限公司

Coal saving material

The invention discloses a coal saving material, which is characterized by comprising the following substances by weight: 20-30 parts of a catalyst, 0-15 parts of a sulfur-fixing agent, 15-19 parts of octadecanoic acid, 1-5 parts of a crosslinking agent sulfur, 5-10 parts of an accelerator, 50-60 parts of high styrene, 30-50 parts of polystyrene, 5-9 parts of a combustion improver, 30-60 parts of silicone modified epoxy resin, 50-80 parts of an inorganic filler, 5-20 parts of an inorganic thickener, 1-2 parts of an yttrium nitrate catalyst and 2-6 parts of a swelling agent. Components in the environment-friendly coal saving agent provided by the invention cooperate with each other to convert flue gas produced in the coal combustion process into coal gas, which combusts with coal, so that the flame is increasing, and emissions of dust and harmful gas are decreased substantially; therefore, the coal saving material plays dual roles of energy saving and environmental protection.

Owner:QINGDAO GUOQIANG ENVIRONMENTAL PROTECTION TECH

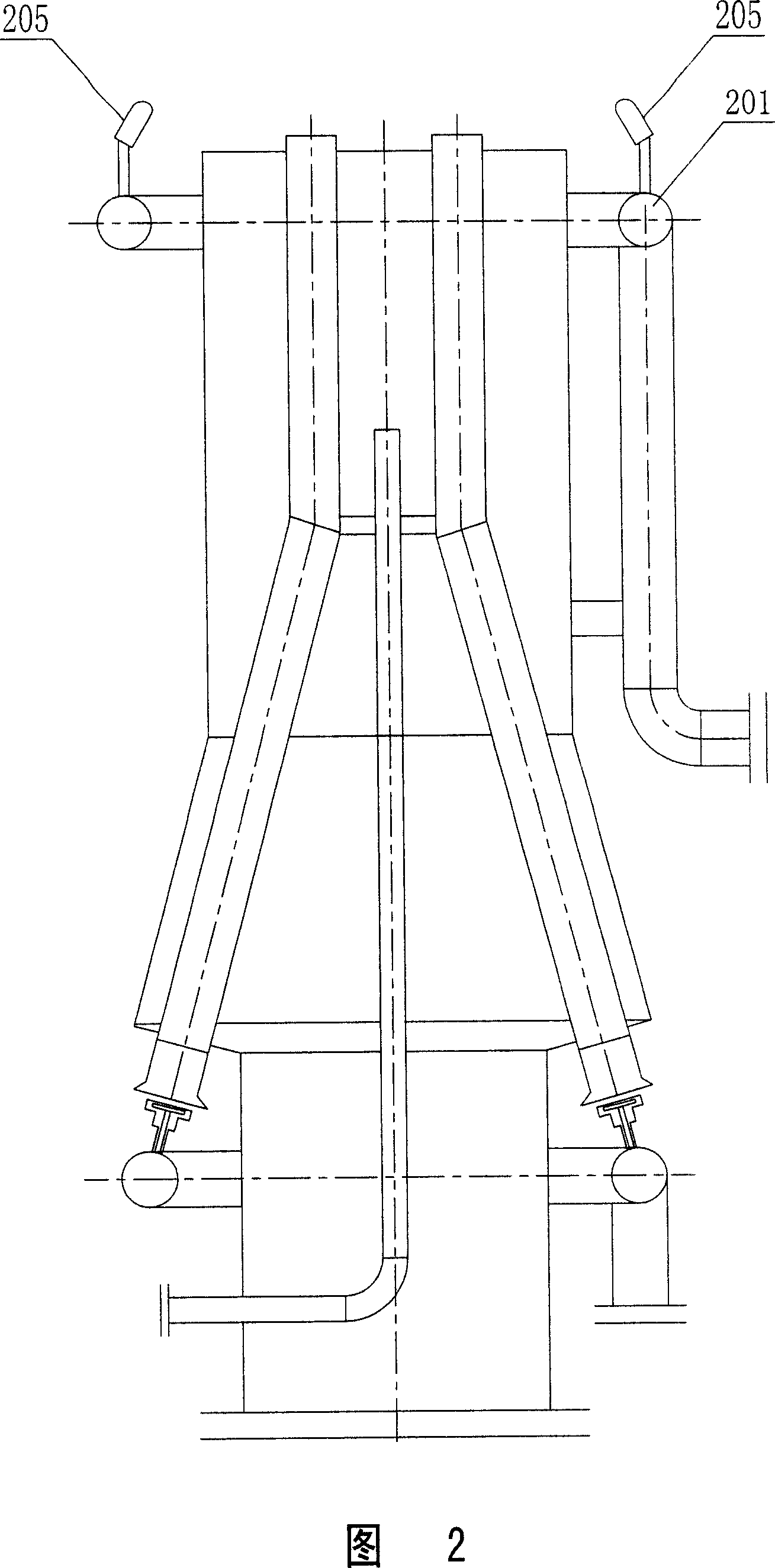

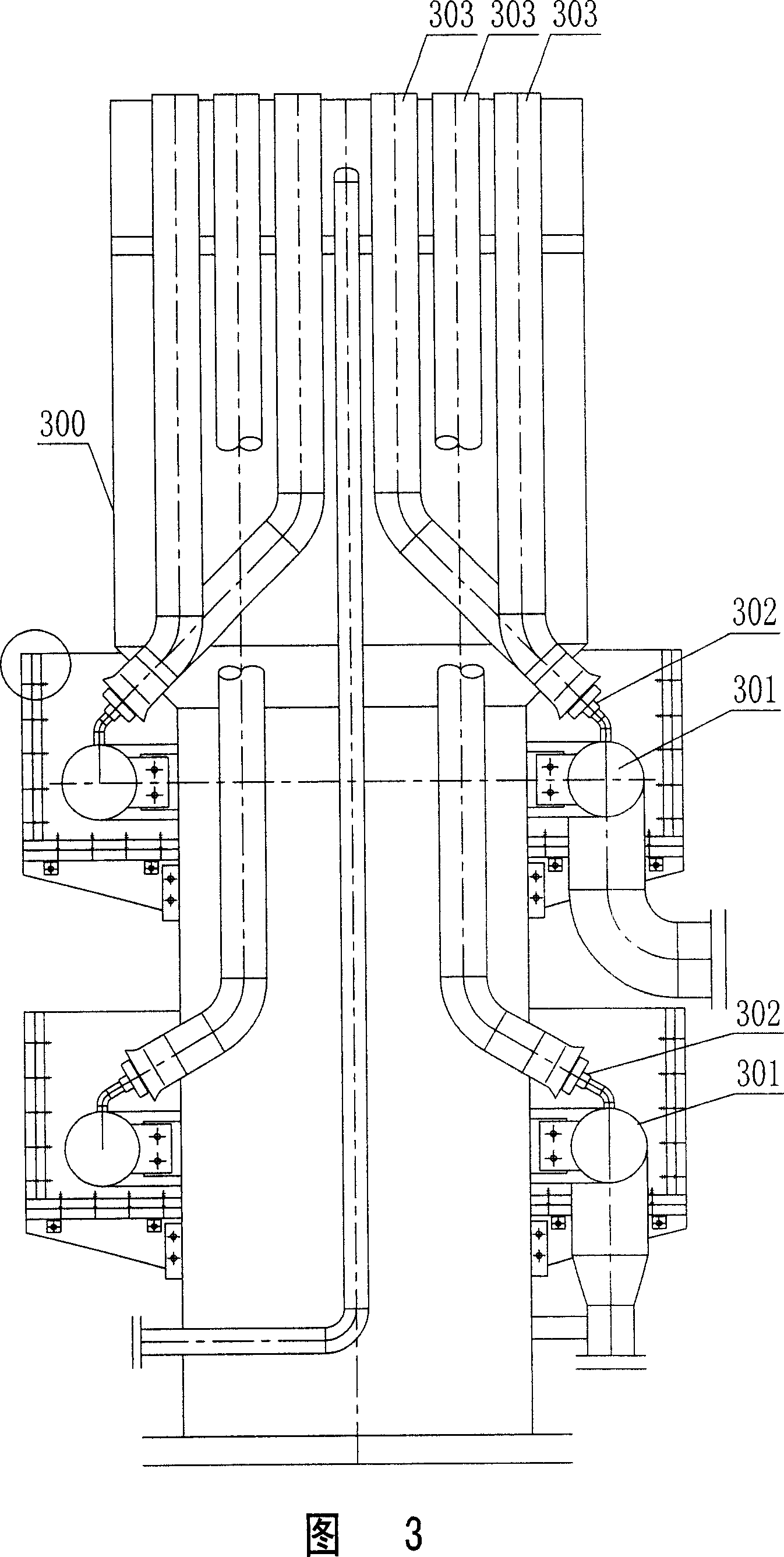

Process nozzle and system for gasifying water coal slurry and application thereof

ActiveCN102031152BEvenly distributedReduced Diffusion ResistanceLiquid spraying apparatusGranular/pulverulent flues gasificationBrickCombustion

The invention provides a process nozzle and a system for gasifying water coal slurry. The process nozzle comprises a first oxygen channel, a water coal slurry channel, a second oxygen channel, a first cooling water jacket and a cooling water coil, wherein the first oxygen channel comprises a first oxygen channel inlet and a first oxygen channel outlet; the water coal slurry channel comprises at least one water coal slurry channel inlet and a water coal slurry channel outlet; the second oxygen channel comprises a second oxygen channel inlet and a second oxygen channel outlet; the first cooling water jacket comprises a first cooling water jacket inlet and a first cooling water jacket outlet; and the cooling water coil comprises a cooling water coil inlet and a cooling water coil outlet. The process nozzle is characterized in that: the first oxygen channel is positioned at the central position of the process nozzle; the water coal slurry channel is positioned between the first oxygen channel and the second oxygen channel and surrounds the periphery of the first oxygen channel; and the second oxygen channel surrounds the periphery of the water coal slurry channel. The process nozzle reduces the length of combustion flame more effectively, reduces the ablation of flame on a refractory brick, promotes the mixing and atomization of water coal slurry and oxygen and improves gasification efficiency.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Low-quality coal pyrolysis device

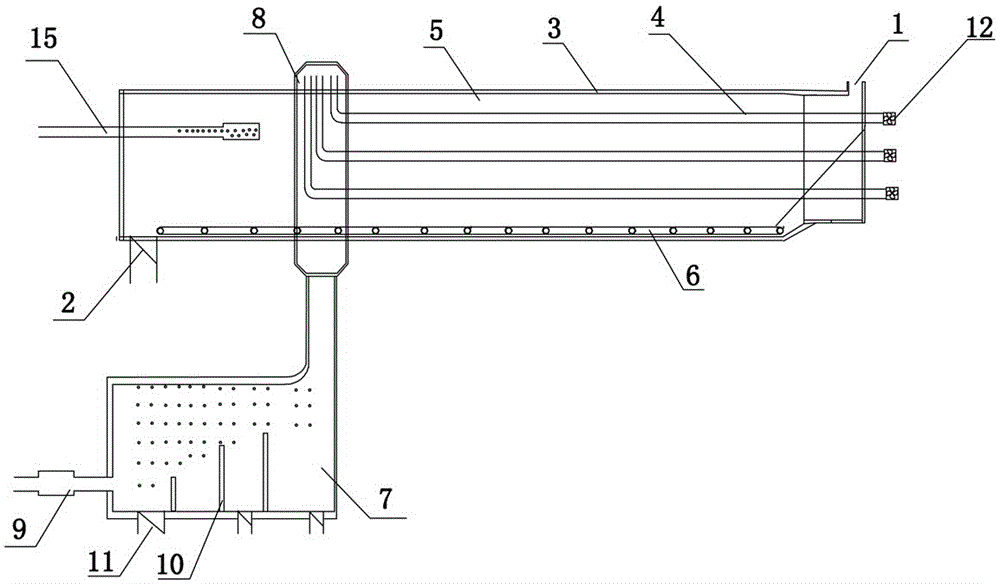

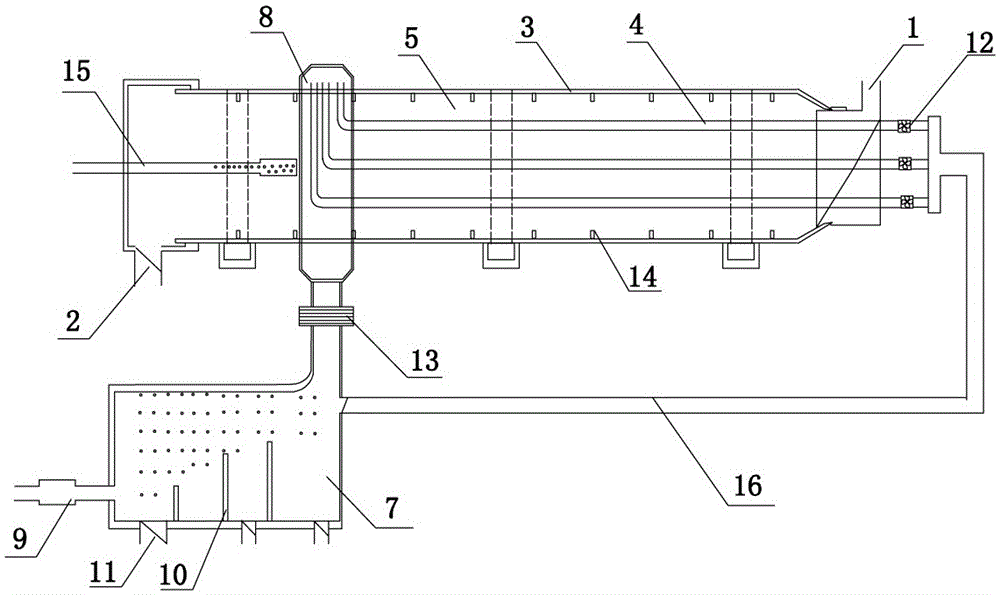

ActiveCN105131990AAddressing Economic Problems with Significant LossesSolve economic problemsSpecial form destructive distillationDecompositionEngineering

The invention discloses a low-quality coal pyrolysis device. The low-quality coal pyrolysis device comprises a closed kiln body with a feed hole and a discharge hole, a high-temperature gas pipeline is arranged in the closed kiln body, a low-quality coal advancing and decomposing channel is formed between the high-temperature gas pipeline and the inner wall of the closed kiln body, and a decomposition gas collecting pipe communicated with the low-quality coal advancing and decomposing channel is arranged on the closed kiln body; the low-quality coal pyrolysis device further comprises a high-temperature gas generating device which is communicated with the high-temperature gas pipeline through a high-temperature gas distributing cover, and the high-temperature gas distributing cover is circumferentially connected with the closed kiln body in a sealing mode. According to the low-quality pyrolysis device, the high-temperature gas generating device is arranged and connected with the high-temperature gas pipeline through the high-temperature gas distributing cover, so that the reliability and stability of the low-quality coal pyrolysis device are improved fundamentally.

Owner:郭秀梅

Preparation method of coal-saving agent used for nitrogen fixation type cement short kiln

ActiveCN109628196ALower reaction energyIncrease the amount of liquid phaseSolid fuelsProcess systemsRare earth

The invention discloses a preparation method of a coal-saving agent used for a nitrogen fixation type cement short kiln. 30-50 parts of rare earth tailings, 10-20 parts of magnesium hydroxide, 15-25 parts of hydrated aluminum oxide are mixed and ground to obtain a mixture; 5-15 parts of aromatic condensates, 5-15 parts of organosilicon polymers and 2-10 parts of zinc borate are added into the mixture, uniform mixing is conducted, and the coal-saving agent used for the nitrogen fixation type cement short kiln is obtained. According to the process system of calcining cement with short flame andrapid burning, high-burning-value coal used in a short-flame kiln is added into the coal-saving mixture coal used in the nitrogen-fixing cement kiln for mixed combustion, compared with combustion of the same amount of raw coal, the NO(x) in coal-burning flue gas is reduced by 50-60%, and the energy consumption of combustion of cement clinker is comprehensively reduced by 5-15%, the formation amount and discharge amount of NO(x) can also be effectively reduced, and the nitrogen fixing effect of the clinker can thus be improved.

Owner:HUBEI UNIV OF TECH

Bauxite shaft kiln combustion device

InactiveCN103542409AIncrease outlet pressureWell mixedGaseous fuel burnerVertical furnacesCombustionPulp and paper industry

The invention relates to a bauxite shaft kiln combustion device which comprises a fuel channel, a hot air channel and a combustion plate. One end of the fuel channel is sealed through a cover plate, a maintenance hole is formed in the cover plate, the other end of the fuel channel is communicated with the hot air channel through a flange, a fuel inlet is formed in the fuel channel, the hot air channel is a double-layer casing pipe, the double-layer casing pipe comprises an inner pipe and an outer pipe, the annular space between the inlet end of the inner pipe and the inlet end of the outer pipe is sealed through a steel board, the inner pipe and the outlet end of the outer pipe are fixed together through the combustion plate, a hot air inlet is formed in the outer pipe, and a plurality of baffle boards which are obliquely arranged along the outer surface of the inner layer of the casing pipe are arranged on the outer surface of the inlet end of the inner pipe. The bauxite shaft kiln combustion device can improve combustion efficiency, energy is saved by more than 30%, consumption is reduced by more than 30%, carbon emissions are reduced, and environmental pollution is reduced.

Owner:河南省新密市久隆耐火材料有限公司

stove cover

ActiveCN110220195BImprove heating efficiencyIncrease flame lengthBurner safety arrangementsDomestic stoves or rangesStructural engineeringHeating efficiency

The invention discloses a stove fire cover. The side wall of the stove fire cover is provided with an outward extending waterproof brim. The stove fire cover is provided with main fire holes and flamestabilizing holes. The main fire holes are distributed in the side wall and located below the waterproof brim. The flame stabilizing holes are formed in the lower surface of the waterproof brim towards the main fire holes. According to the stove fire cover, the flame stabilizing holes for stabilizing flames of the main fire holes are formed in the specific positions of the lower surface of the waterproof brim so that the length of the flames of the main fire holes located in the lower end of the waterproof brim can be increased, the flames can further outwards extend, and accordingly, under the situation that the extending length of the waterproof brim is large, the flames can be prevented from being hindered by the waterproof brim, so that the heating efficiency of the stove fire cover is improved, and meanwhile the off-flame situation can be avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Fuel step adding apparatus of glass melter total oxygen combustion

InactiveCN101381196BSpread evenlyIncrease flame lengthGlass furnace apparatusCombustion regulationCombustorGlass melting

The invention provides a hierarchical adding device for total-oxygen combustion fuel of glass melting furnaces. The device mainly comprises a main fuel pipe (2), a combustion-supporting oxygen pipe (7), a main burner (11), minor fuel pipes (12), as well as valves which are connected with the bodies of the combustion-supporting oxygen pipe (7), the main fuel pipe and the minor fuel pipes and play a certain role in controlling and regulating, wherein the main burner (11) has a casing-type structure and is sleeved with the body of the right part of the main fuel pipe (2); two minor fuel pipes (12) are provided, are symmetrically distributed on two sides of the main burner (11), and are parallel to the main burner; and the right end of the body of the combustion-supporting oxygen pipe (7) is connected and communicated with the main burner through a bent pipe. The device regulates the length, coverage area, temperature and other parameters of flame by adjusting the amount of fuel used between the main burner and the two minor fuel pipes so as to ensure the complete combustion of the fuel, has the advantages of saving energy, reducing emission, benefiting environmental protection and the like, and is especially applicable to total-oxygen combustion glass melting furnaces which takes natural gas as fuel.

Owner:WUHAN UNIV OF TECH

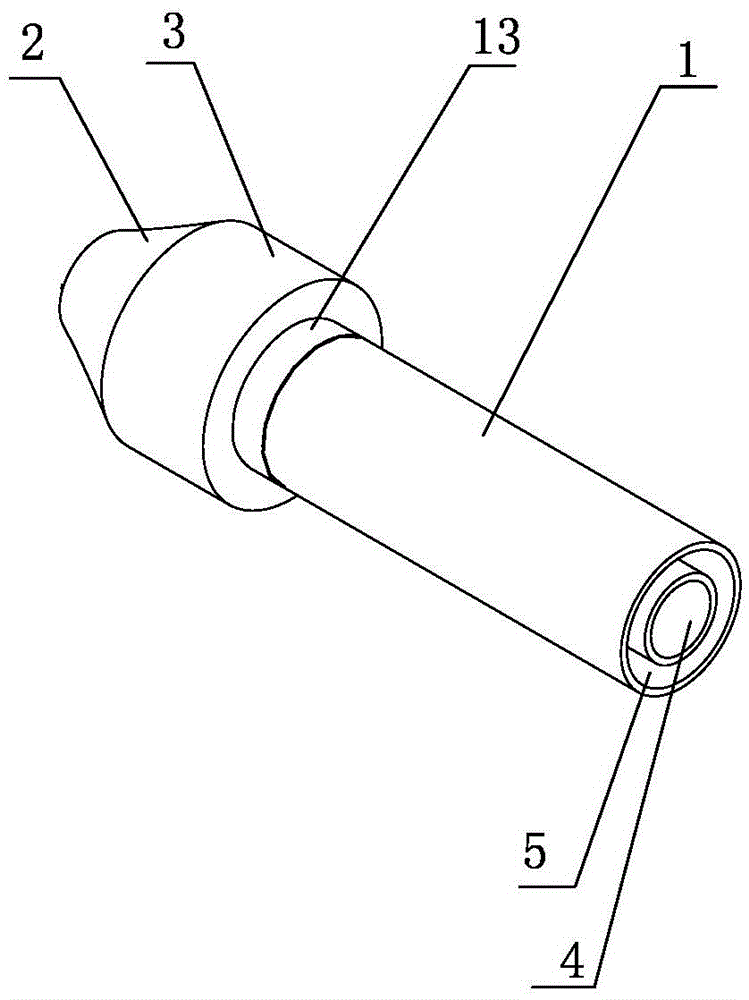

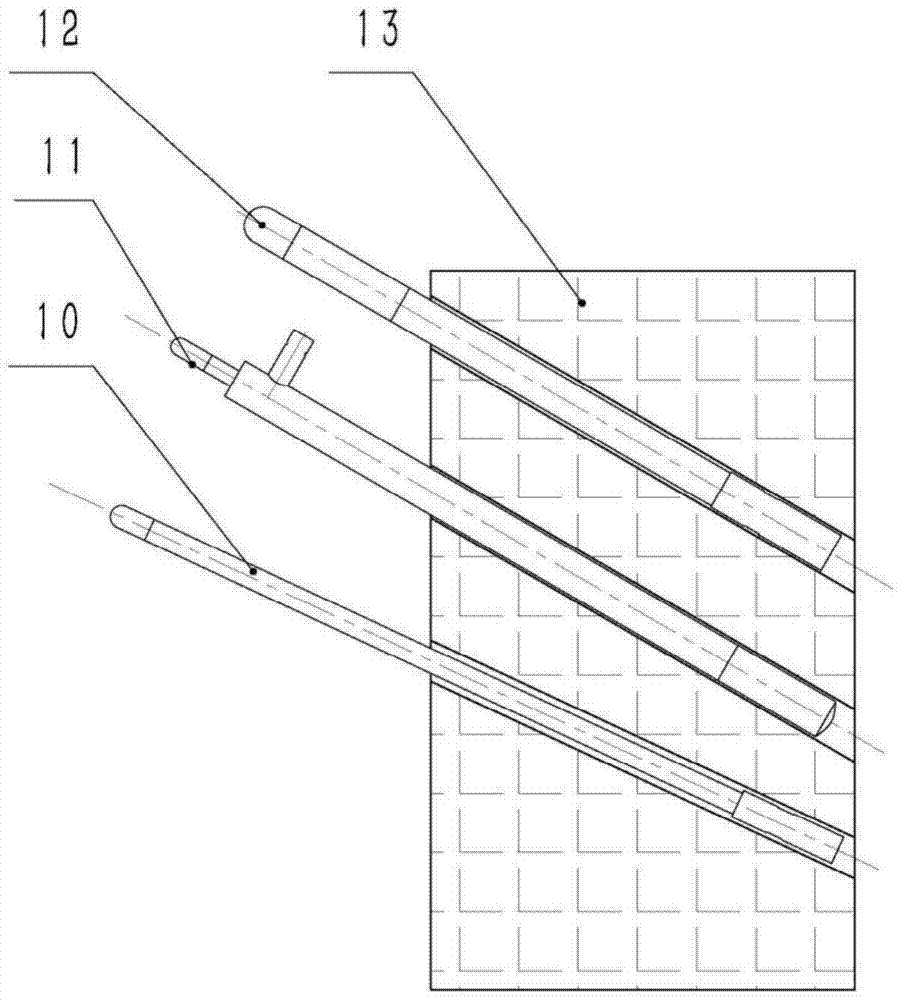

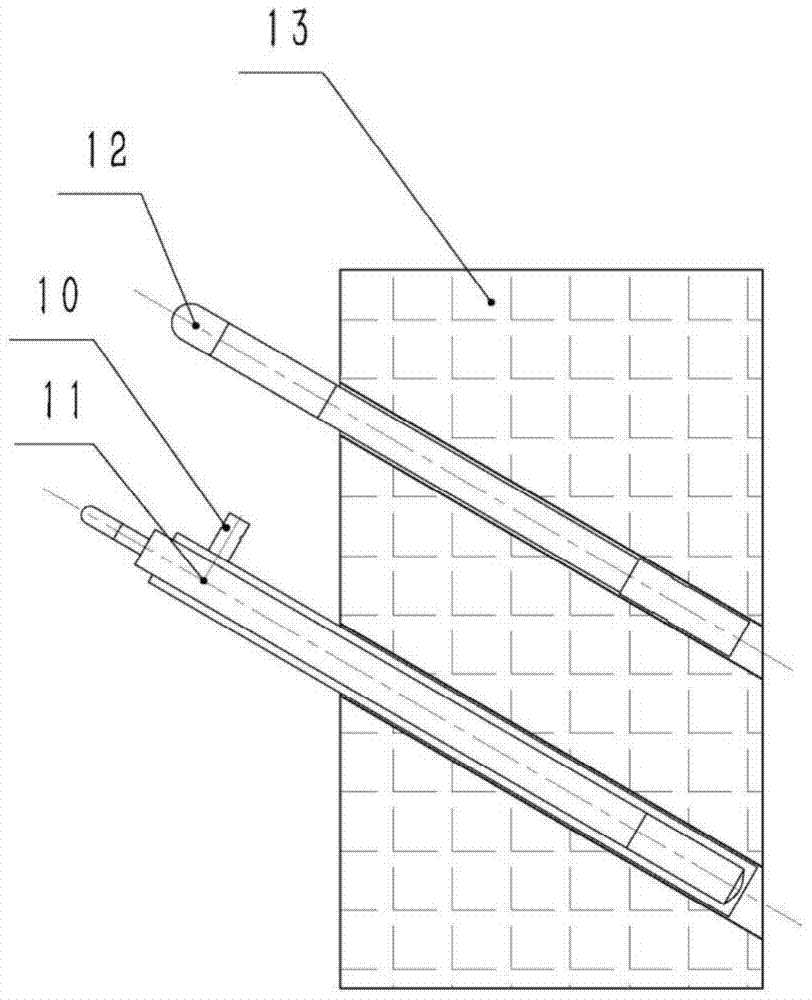

Flame-adjustable burner, and installation structure and application method thereof

PendingCN108759460AShorten the travel distanceFree from high temperature burningRotary drum furnacesCombustorEngineering

The invention relates to a flame-adjustable burner, and an installation structure and an application method thereof. The flame-adjustable burner comprises a burner body, air pipes, gas pipes and flowmeasuring and adjusting devices, wherein the air pipes and the gas pipes are connected with the burner body; the flow measuring and adjusting devices are arranged on the air pipes and the gas pipes. The burner body is provided with a center air duct, an inner ring gas duct, an inner ring air duct, an outer ring gas duct and an outer ring air duct from inside to outside in sequence. The flame-adjustable burner provided by the invention is adjustable in flame length, contour and air-fuel ratio. Gas and distributed air can be uniformly and completely mixed. While the calcinations temperature is satisfied, and low-NOx emission can be realized; moreover, the flame-adjustable burner is capable of being automatically adjusted, safe and controllable in the burning process. The flame-adjustable burner has two working positions and can meet the requirements for normal operation and ignition, realize angle fine adjustment through a flexible seal and ensure that flames do not sweep a kiln liner.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

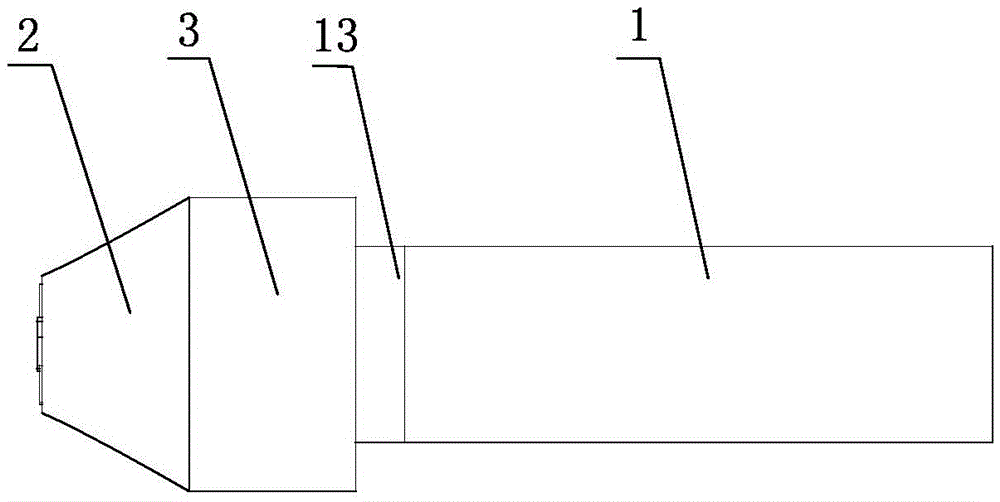

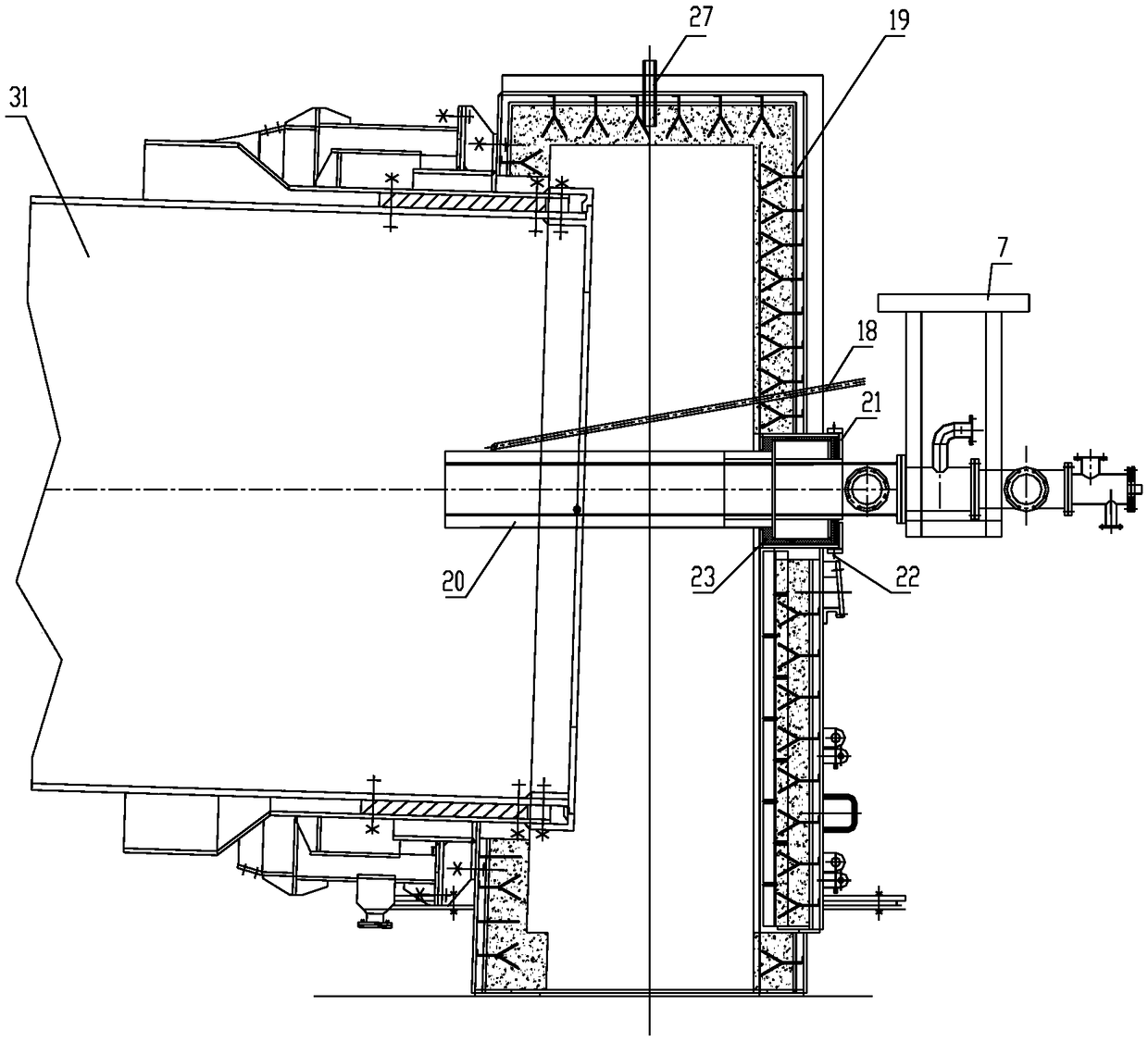

A kind of multi-oxygen oblique flame burning method and burning device of flat glass melting furnace

ActiveCN105217932BSimple structureFlexible and convenient layoutGlass furnace apparatusGlass productionFlat glassCombustor

The invention relates to an oxygen-rich inclined-flame combustion method of a flat glass melting furnace and a combustion device. The combustion device comprises a feeder nose, a melting part, a neck and a cooling part. A breast wall is arranged outside the melting part. The breast wall, close to left and right sides of the feeder nose, is provided with smoke vents. Several oxygen-rich inclined-flame combustors are arranged at intervals at left and right sides of the breast wall. The included angle between flame of the oxygen-rich inclined-flame combustors and the breast wall is 30-150 degrees. Each oxygen-rich inclined-flame combustor contains a spray gun and a burner block, wherein the spray gun comprises an oxygen spray gun and a fuel spray gun. The oxygen-rich inclined-flame combustor also comprises a control part which adopts subsection control. According to a temperature curve of a glass melting furnace, distribution ratio of each section of combustor for conveying fuel is set. By an oxygen-rich inclined-flame combustion mode, temperature field and airflow field inside the glass melting furnace are optimized, heat exchange efficiency can be enhanced, erosion of exhaust gas to furnace crown is minimized, and service life of the glass melting furnace is prolonged.

Owner:王立臣

Bauxite shaft kiln combustion device

InactiveCN103542409BIncrease outlet pressureWell mixedGaseous fuel burnerVertical furnacesCombustionCoesite

Owner:河南省新密市久隆耐火材料有限公司

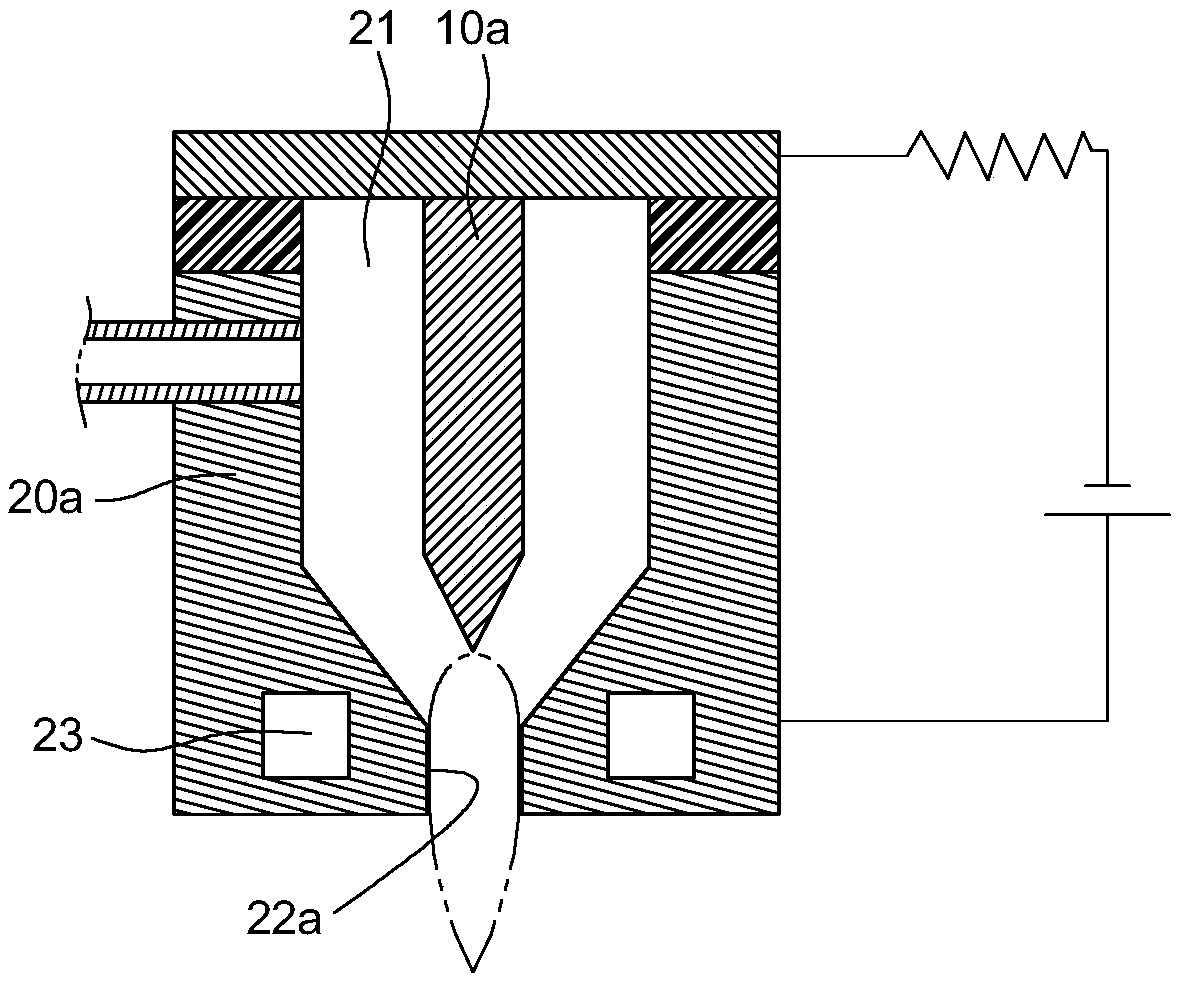

Electricity thick liquid torch trigger device

Owner:ORIENT SERVICE

Modified furfural residue biomass coal saving agent

ActiveCN113862055AAchieve reuseIncrease economic value addedSolid fuelsWaste based fuelActive agentEngineering

The invention discloses a modified furfural residue biomass coal-saving agent. Modified furfural residues are taken as a main raw material and compounded with an active agent and an oxygen producer to obtain the biomass coal-saving agent, and the coal-saving agent has the effects of catalytic combustion and efficient sulfur fixation, and is simple to operate, low in cost and beneficial to industrial popularization.

Owner:SHANDONG ZHONGSEN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com