Process nozzle and system for gasifying water coal slurry and application thereof

A process burner and coal-water slurry technology, applied in the field of coal gasification, can solve the problems of shortening the service life of the gas generator, burner erosion wear, burner abrasion, etc., and achieve the effect of effective protection and efficient cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

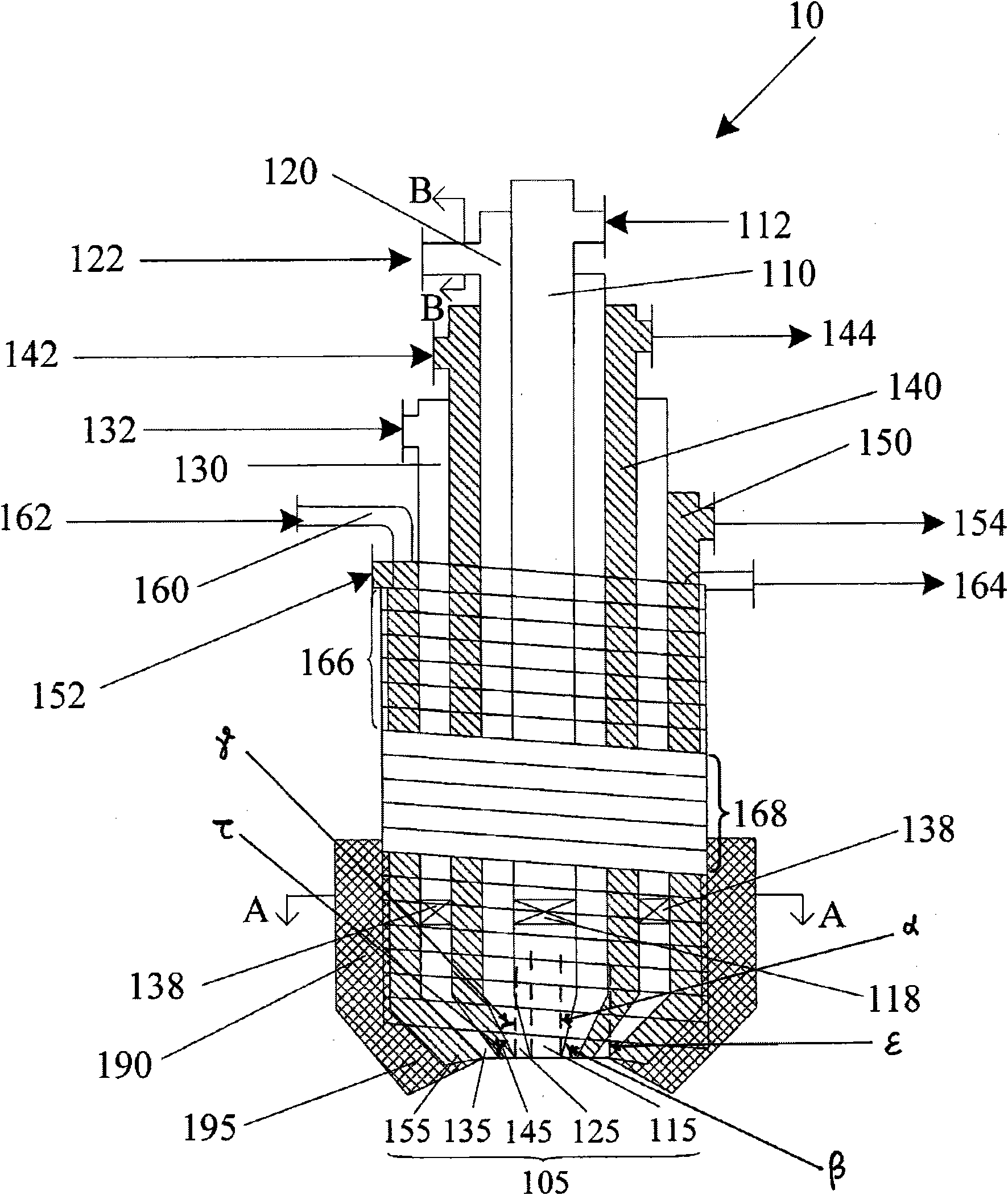

[0118] Such as figure 1 Shown, provide a kind of novel process burner 10 for coal-water slurry gasification of the present invention, specifically include:

[0119] First oxygen channel 110 (also referred to as central oxygen channel 110), this first oxygen channel includes first oxygen channel inlet 112 and first oxygen channel outlet 115; coal water slurry channel 120, this coal water slurry channel includes at least one water Coal slurry channel inlet 122 and coal water slurry channel outlet 125; The second cooling water jacket 140, this second cooling water jacket includes the second cooling water jacket inlet 142 and the second cooling water jacket outlet 144, the second The cooling water jacket 140 shrinks to the center line of the cylinder at the spout 105; the second oxygen channel 130 (also referred to as the outer epoxy channel 130), which includes the second oxygen channel inlet 132 and the second oxygen channel Exit 135.

[0120] Wherein, the first oxygen channel...

Embodiment 2

[0126] still as figure 1 As shown, the outer surface of the cooling water coil 160 of the process burner 10 in Embodiment 1 is located at the head of the process burner and is also covered with a high temperature resistant, wear and corrosion resistant shell 190, which is made of high temperature resistant, wear and corrosion resistant materials. Such as a wear-resistant ceramic layer, or using Hastenoy C-22, UMCo-50 and other materials for multiple protection, so that the process burner of the present invention is more durable.

[0127] Moreover, the cooling water coil 160 of the process burner 10 of the present invention is closely wound around the periphery of the first cooling water jacket 150 of the burner 10 , and the coils of each layer are welded together as a whole.

[0128] The burner head 105 and the cooling water coil 160 of the burner are made of materials with good wear resistance, thermal shock resistance and sulfur corrosion resistance. The burner head 105 is m...

Embodiment 3

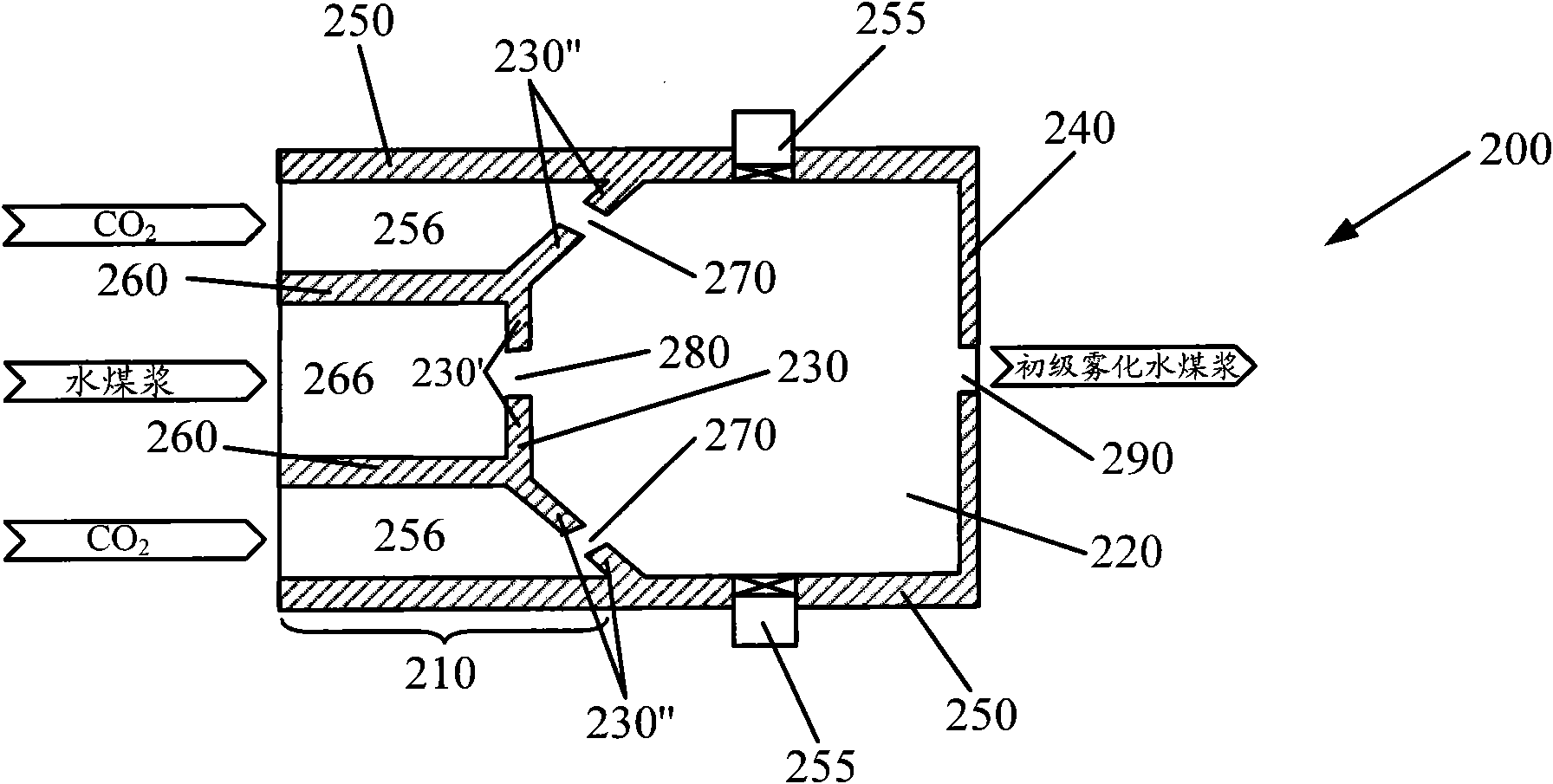

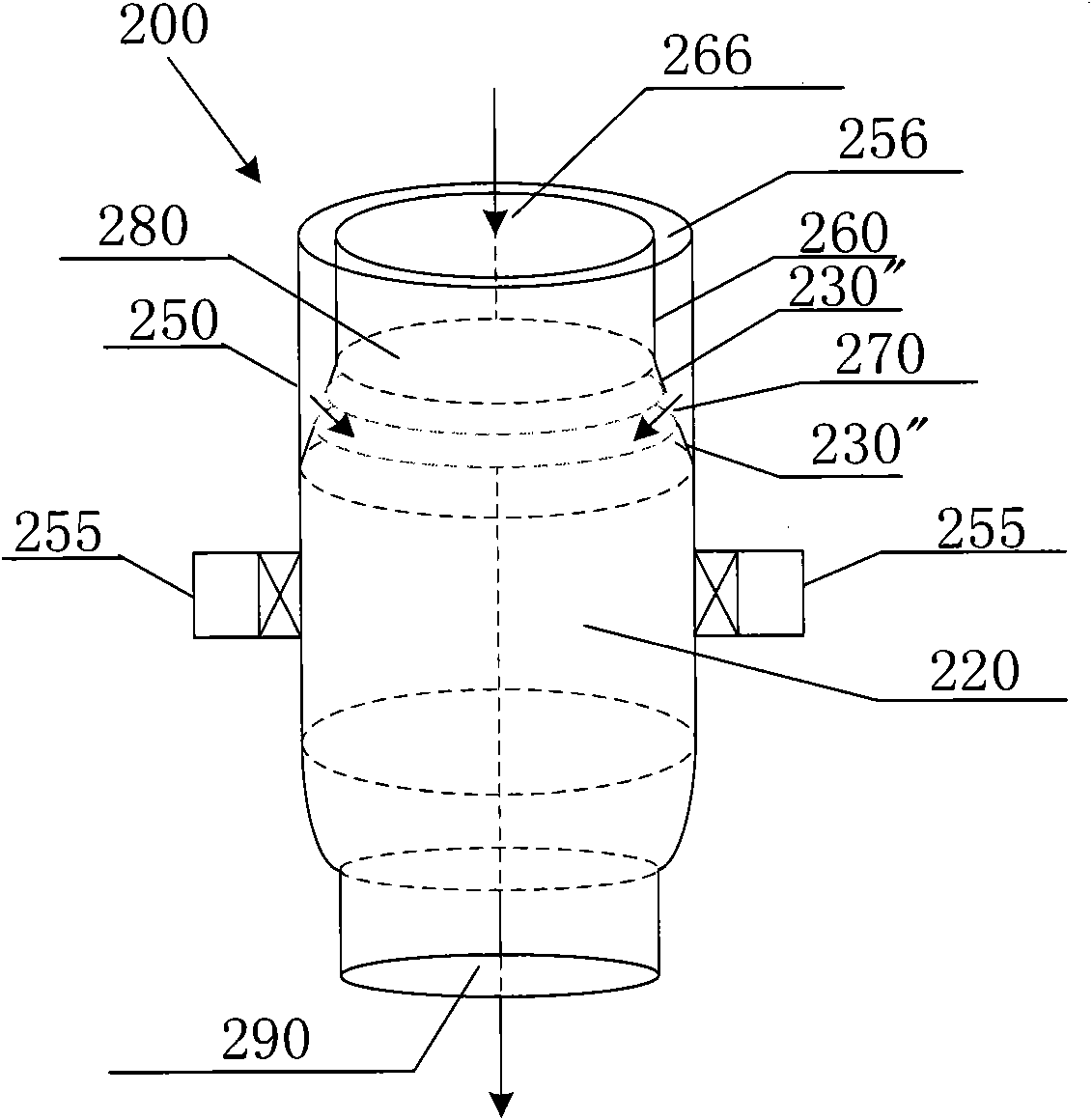

[0163] As the process nozzle 10 of embodiment 1, wherein the pipeline at the inlet 122 of the coal-water slurry channel is as Figure 3a As shown, the pipeline at the coal-water slurry channel inlet 122 is located in the tangential direction of the coal-water slurry channel 120, so that the coal-water slurry / carbon dioxide (primary atomized coal-water slurry) enters the water along the tangential direction of the cylindrical burner 10 Coal slurry annular channel 120.

[0164] Similarly, as shown in 3b, the pipeline at the inlet 122 of the coal-water slurry channel is located in the tangential direction of the coal-water slurry channel 120 and has double inlet channels 122 .

[0165] In order to further strengthen the effect of the natural spiral flow produced by the guidance of the feed pipeline, the tangential direction pipeline located at the coal-water slurry channel 120 at the inlet 122 of the coal-water slurry channel can have a plurality of inlet channels 122, such as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com