Fuel step adding apparatus of glass melter total oxygen combustion

A technology of glass melting furnace and oxy-fuel combustion, which is applied in glass production, controlled combustion, and glass furnace equipment. Effects of overheating and increased coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

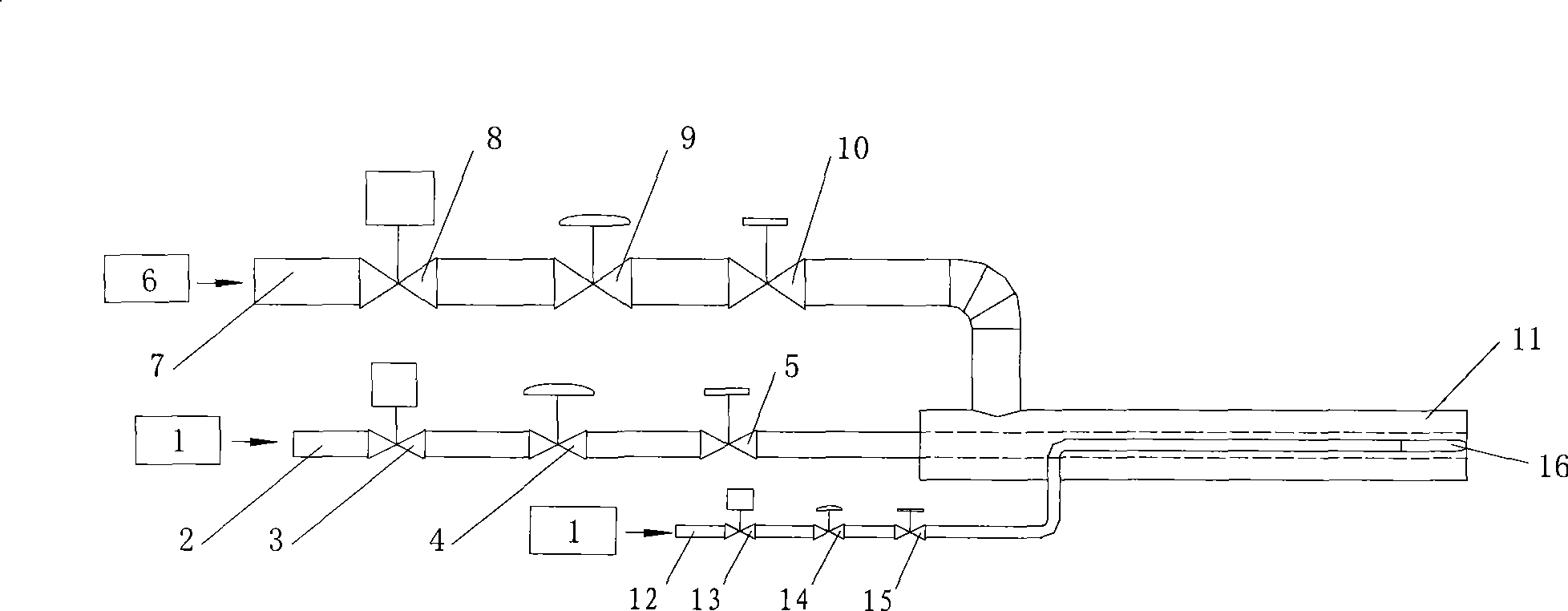

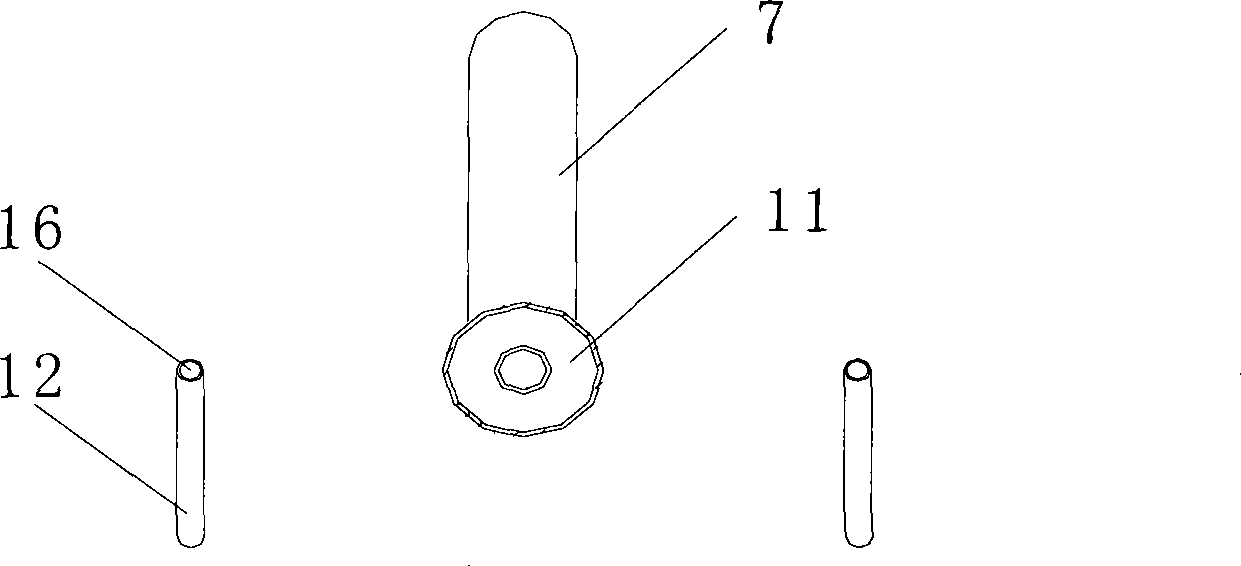

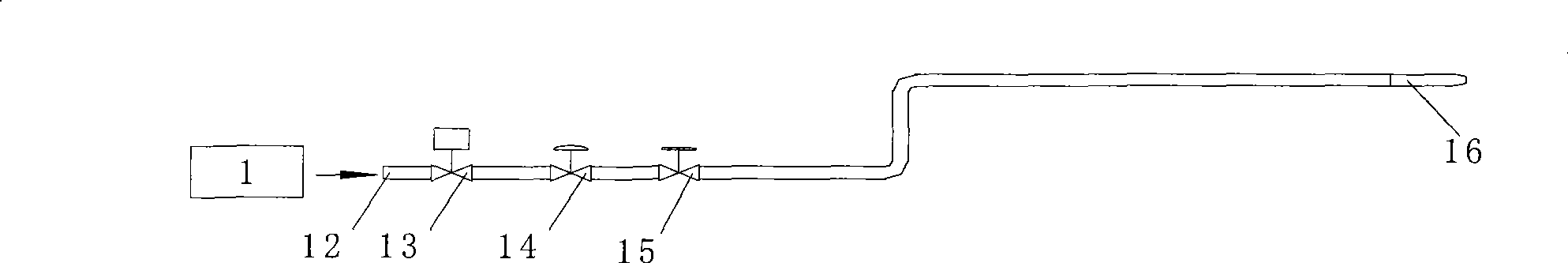

[0024] The oxy-combustion fuel stage adding device for a glass melting furnace provided by the present invention is horizontally installed on the breast wall of the glass melting furnace through nozzle bricks. Such as figure 1 As shown in Figure 4, the device is mainly composed of the main fuel pipe 2, the combustion-supporting oxygen pipe 7, the main burner 11 and the auxiliary fuel pipe 12, as well as the opening adjustment actuators, solenoid valves, Globe valve composition. There are two sets of auxiliary fuel pipes 12 with the same internal structure and symmetrically distributed on both sides of the main fuel pipe 2 . Among them: the pipe body of the main fuel pipe 2, the left end of which is connected to the fuel source 1 through a hose, and the opening adjustment actuator 3 of the fuel pipeline, the solenoid valve 4 of the main burner and the Main burner cut-off valve 5, further to the right this pipe body is connected with the main burner 11 sets of casing type stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com