Biomass steam boiler secondary air distribution system

A technology of air distribution system and steam boiler, which is applied to the transportation of non-flammable liquid/gas, combustion method, combustion equipment, etc. It can solve the problems of easy ignition of biomass fuel, easy damage of slag machine motor, and low thermal efficiency of boilers. Achieve the effect of reducing excess air coefficient, reducing maintenance rate and prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

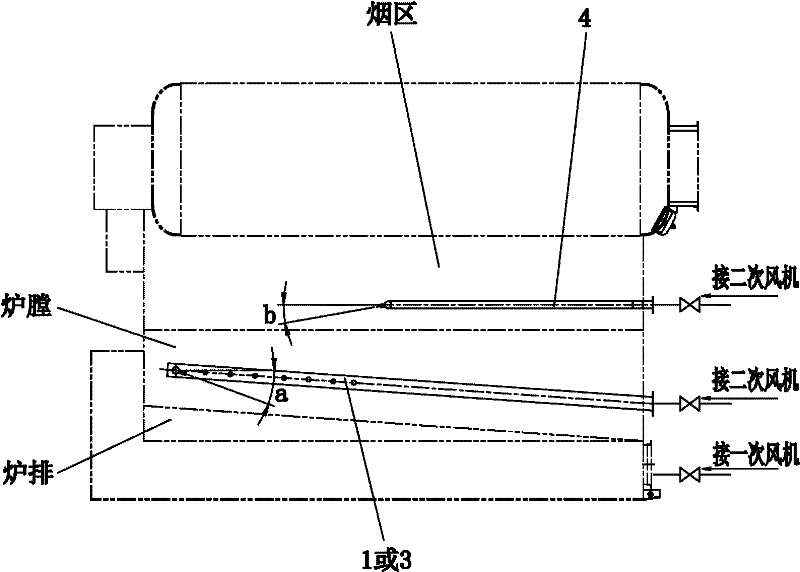

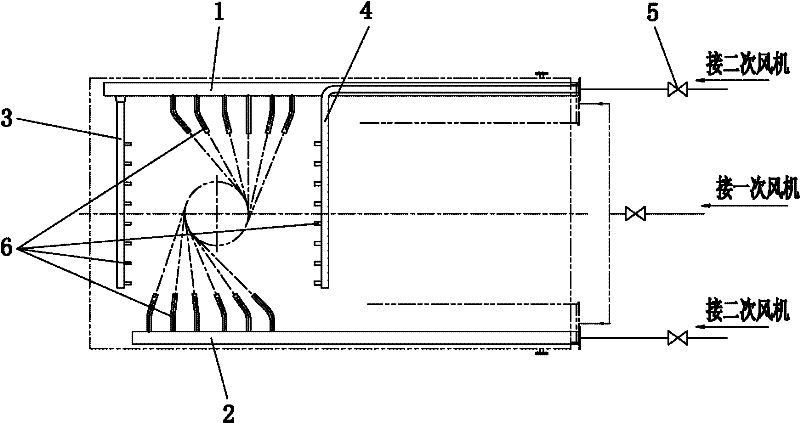

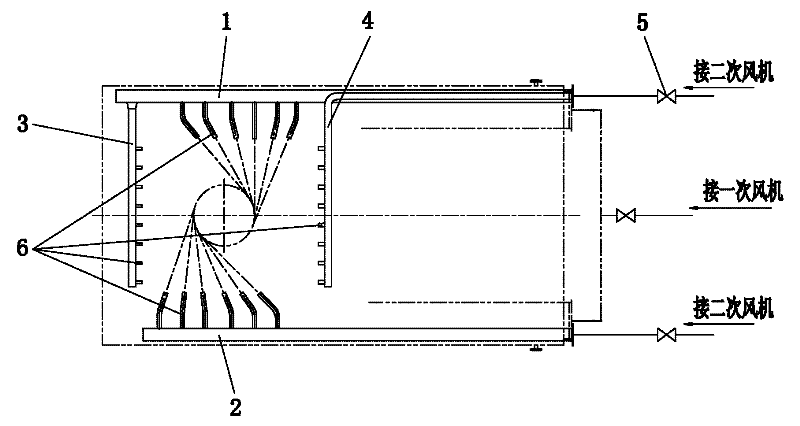

[0013] The secondary air distribution system of the biomass steam boiler consists of the left air duct 1, the right air duct 2, the front wall air duct 3 and the rear arch air duct 4. The left air duct 1 and the right air duct 2 are arranged on the top of the fire grate, and they are arranged longitudinally (the front and back direction of the furnace is the longitudinal direction, that is, the same as the forward direction of the fire grate) on the left and right sides of the fire grate. The center line of the left air duct 1 and the right air duct 2 is parallel to the longitudinal plane of the grate, that is, the grate plane is inclined, and the left air duct 1 and right air duct 2 are from the rear of the furnace to the front of the furnace The upper part is arranged obliquely upward, and the inclination angle is about 3-10°. The front wall air duct 3 is arranged above the fire grate and arranged horizontally (perpendicular to the direction of fire grate advance) above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com